OM-284794 Page 14

F

Complete Parts List is available at www.MillerWelds.com

SECTION 4 – SPECIFICATIONS

4-1. Serial Number And Rating Label Location

The serial number and rating information for the power source is located on the rear of the machine. Use the rating labels to determine input

power requirements and/or rated output. For future reference, write serial number in space provided on back cover of this manual.

4-2. Software Licensing Agreement

The End User License Agreement and any third-party notices and terms and conditions pertaining to third-party software can be found at

https://www.millerwelds.com/eula and are incorporated by reference herein.

4-3. Information About Default Weld Parameters And Settings

NOTICE – Each welding application is unique. Although certain Miller Electric products are designed to determine and default to certain typical

welding parameters and settings based upon specific and relatively limited application variables input by the end user, such default settings are

for reference purposes only; and final weld results can be affected by other variables and application-specific circumstances. The appropriate-

ness of all parameters and settings should be evaluated and modified by the end user as necessary based upon application-specific require-

ments. The end user is solely responsible for selection and coordination of appropriate equipment, adoption or adjustment of default weld

parameters and settings, and ultimate quality and durability of all resultant welds. Miller Electric expressly disclaims any and all implied warran-

ties including any implied warranty of fitness for a particular purpose.

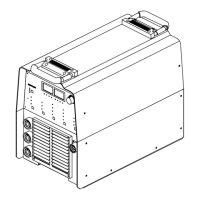

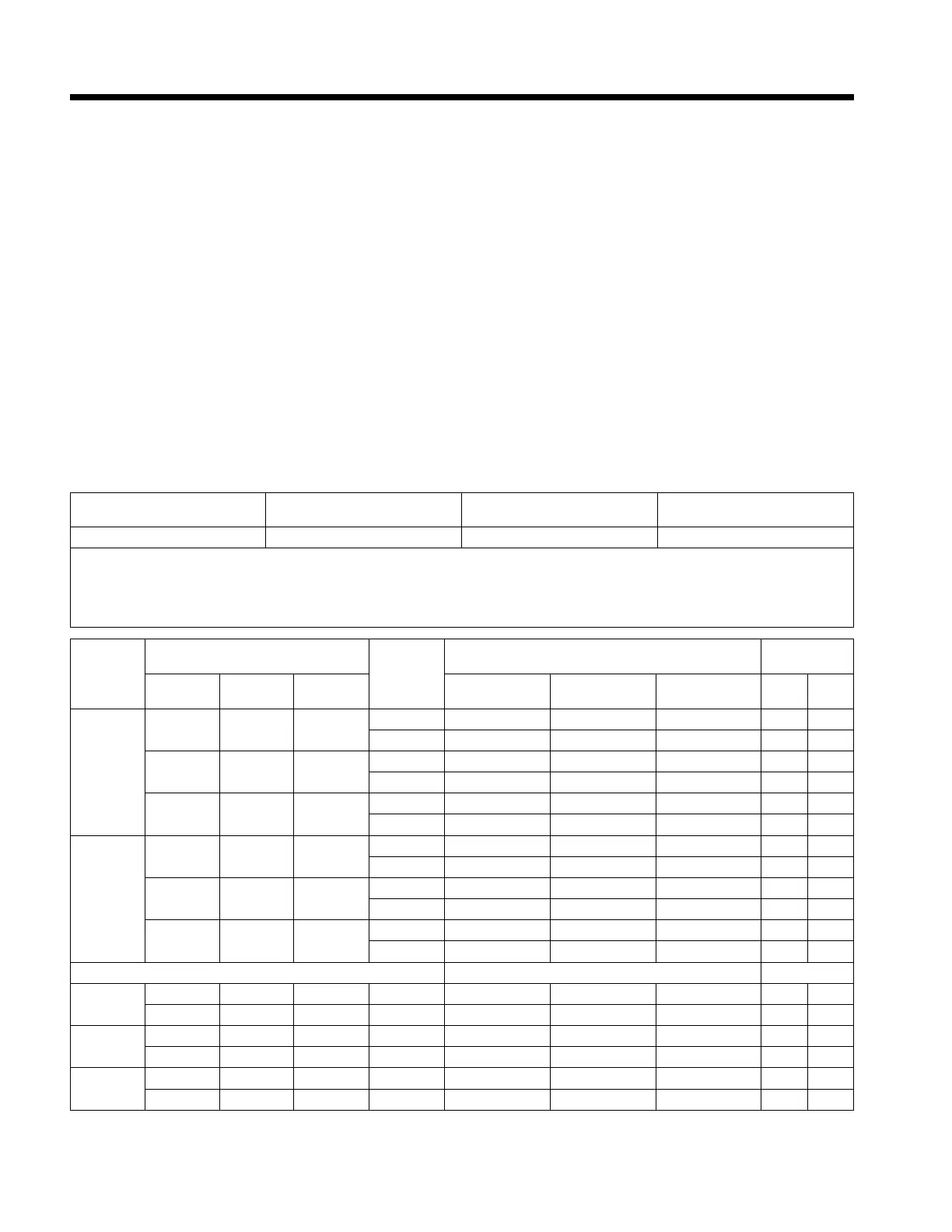

4-4. Welding Power Source Specifications

F

This equipment will deliver rated output at an ambient air temperature up to 104° F ( 40° C).

F

Do not use information in unit specifications table to determine electrical service requirements. See Sections 5-6, 5-7 and 5-8 for informa-

tion on connecting input power.

Welding Amperage Range Max Open-Circuit Voltage

(U

0

)

Low Open-Circuit Voltage

(U

0

)

Rated Peak Striking Voltage

(U

p

)

5-300

1

60 8-15

2

14KV

3

1

Welding range for Stick process is 5-230 amperes. For TIG, the amperage range is tungsten diameter dependent (see Section ).

2

Low open-circuit voltage while in TIG Lift Arc

™

, or while in Stick with low open-circuit voltage selected.

3

Arc starting device is designed for manual guided operations.

Process

Output Ratings

Phase

Current Draw (A) At Rated

Input Voltages (V)

Input Power

Current

(A)

Voltage

(V)

Duty

Cycle

208V 240V 480V kW kVA

STICK

230 28.4 30%

1 44 37 18 8.8 9

3 25 22 11 8.6 8.9

160 26.4 60%

1 27 24 12 5.5 5.7

3 16 14 7 5.5 5.7

125 25 100%

1 20 18 9 4.1 4.2

3 12 11 5 4.2 4.3

TIG*

300 22 30%

1 47 41 19 9.4 9.7

3 27 23 11 9.2 9.7

210 18.4 60%

1 27 24 12 5.5 5.7

3 16 14 7 5.5 5.9

175 17 100%

1 22 19 9 4.1 4.2

3 13 11 6 4.3 4.8

Power Draw (W)

Idle OCV

0 60 — 1 90 89 116 — —

0 60 — 3 94 94 131 — —

Idle w/

Output Off

— — — 1 29 30 63 — —

— — — 3 31 34 64 — —

Idle Cooler

On

— — — 1 189 211 250 — —

— — — 3 197 221 278 — —

*Includes cooler power draw.

Loading...

Loading...