OM-284794 Page 19

F

Complete Parts List is available at www.MillerWelds.com

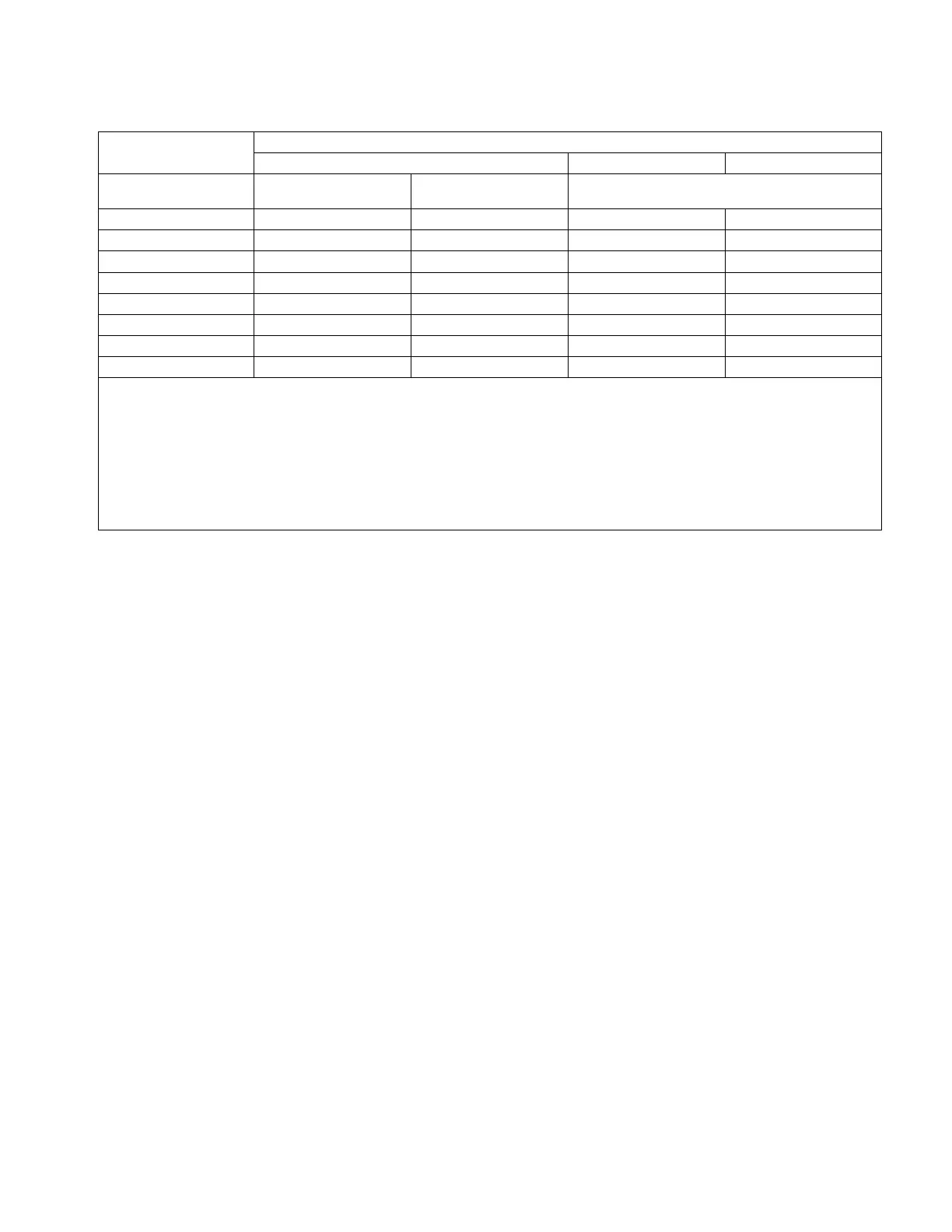

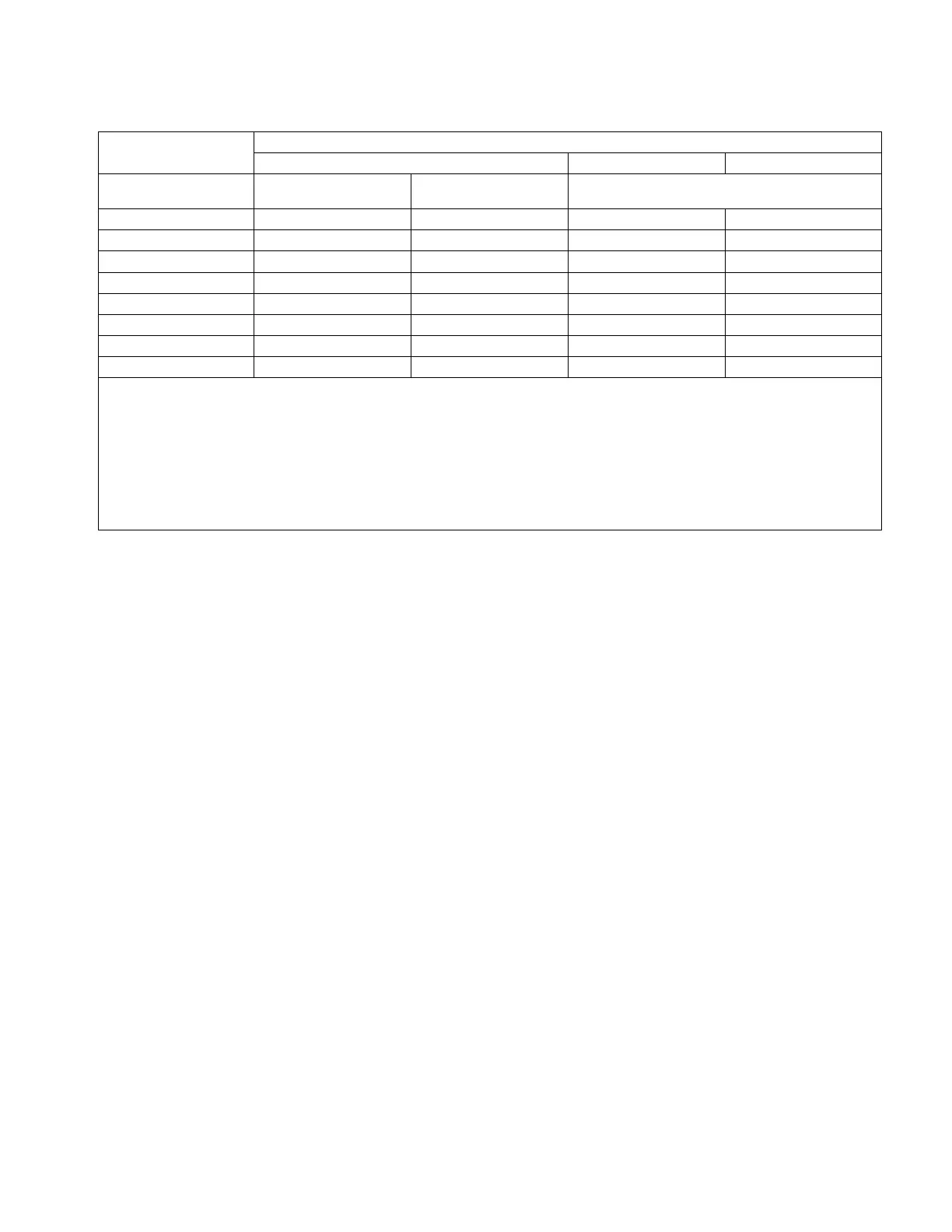

5-2. Selecting Cable Sizes

1

NOTICE – The Total Cable Length in Weld Circuit (see table below) is the combined length of both weld cables. For example, if the power source

is 100 ft (30 m) from the workpiece, the total cable length in the weld circuit is 200 ft (2 cables x 100 ft). Use the 200 ft (60 m) column to determine

cable size.

Weld Cable Size

2

and Total Cable (Copper) Length in Weld Circuit Not Exceeding

100 ft (30 m) or Less

4

150 ft (45 m) 200 ft (60 m)

Welding Amperes

3

10 - 60% Duty Cycle

AWG (mm

2

)

60 - 100% Duty Cycle

AWG (mm

2

)

10 - 100% Duty Cycle

AWG (mm

2

)

100 4 (20) 4 (20) 4 (20) 3 (30)

150 3 (30) 3 (30) 2 (35) 1 (50)

200 3 (30) 2 (35) 1 (50) 1/0 (60)

250 2 (35) 1 (50) 1/0 (60) 2/0 (70)

300 1 (50) 1/0 (60) 2/0 (70) 3/0 (95)

350 1/0 (60) 2/0 (70) 3/0 (95) 4/0 (120)

400 1/0 (60) 2/0 (70) 3/0 (95) 4/0 (120)

500 2/0(70) 3/0 (95) 4/0 (120) 2x2/0 (2x70)

1

This chart is a general guideline and may not suit all applications. If cable overheats, use next size larger cable.

2

Weld cable size (AWG) is based on either a 4 volts or less drop or a current density of at least 300 circular mils per ampere.

( ) = mm

2

for metric use.

3

Select weld cable size for pulsing application at peak amperage value.

4

For distances longer than 100 ft (30 m) and up to 200 ft (60 m), use direct current (DC) output only. For distances longer than those shown in

this guide, see AWS Fact Sheet No. 39, Welding Cables, available from the American Welding Society at http://www.aws.org.

Loading...

Loading...