OM-284794 Page 17

F

Complete Parts List is available at www.MillerWelds.com

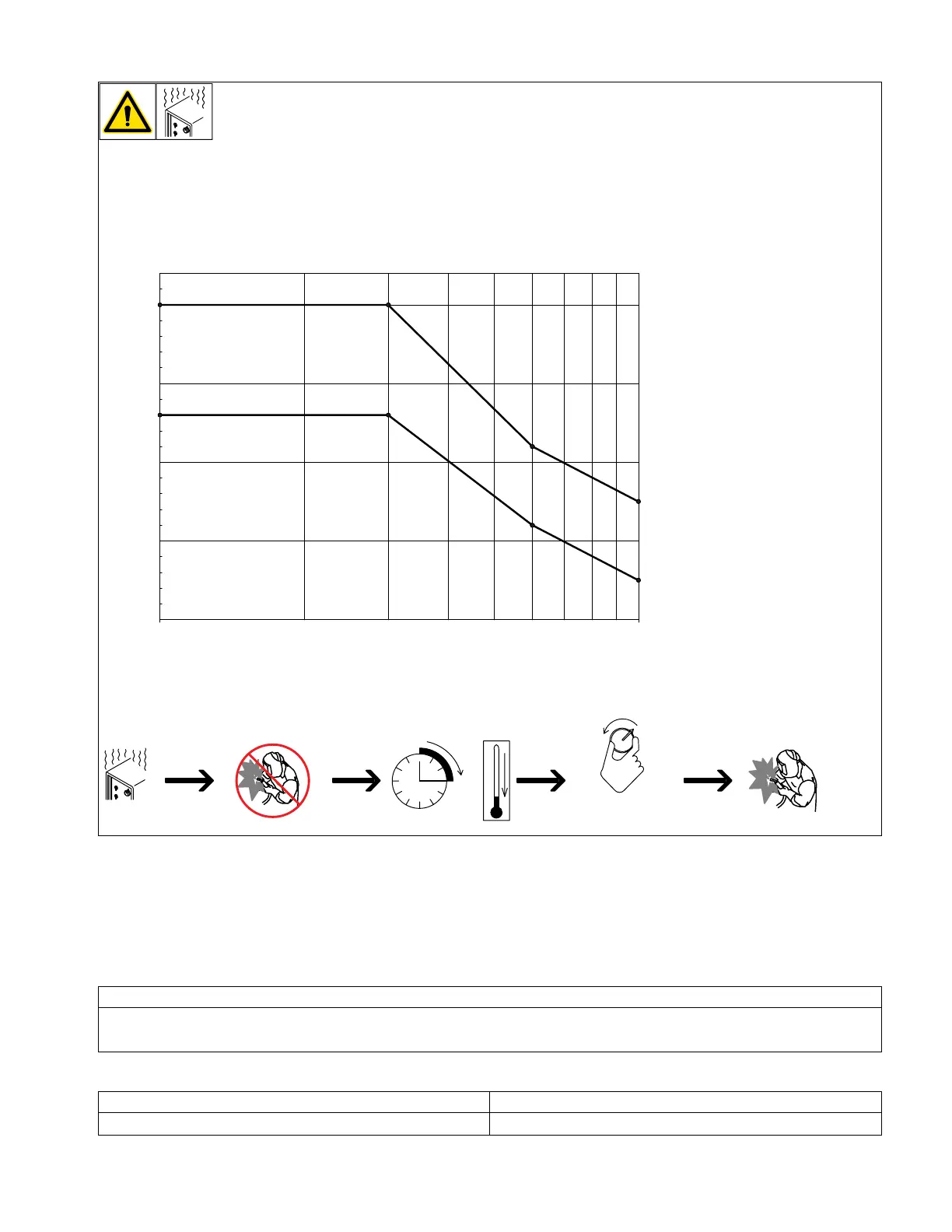

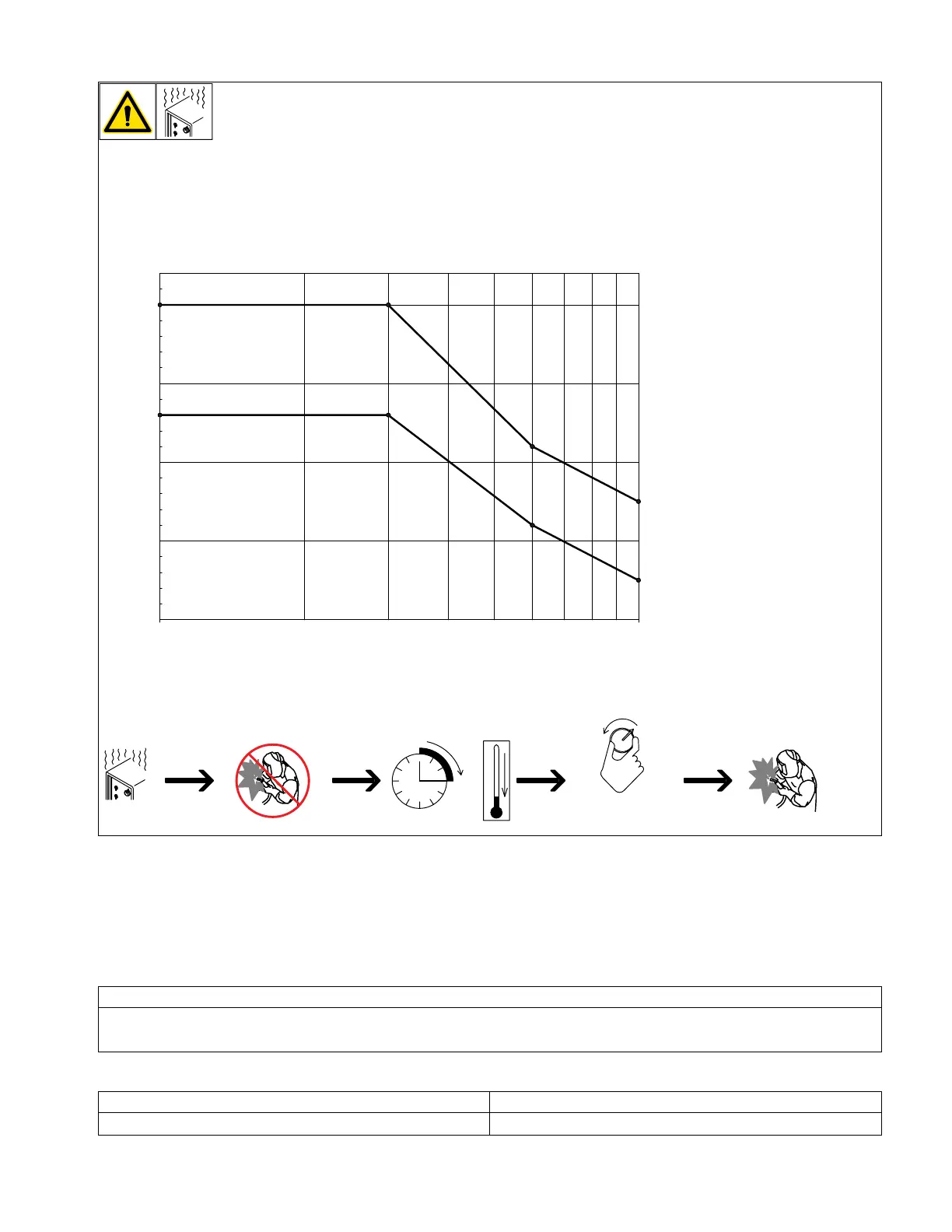

4-8. Duty Cycle And Overheating

Duty Cycle is percentage of 10 minutes that

unit can weld at rated load without

overheating.

If unit overheats, output stops, a Help mes-

sage is displayed (see Section 8-4), and cool-

ing fan runs. Wait fifteen minutes for unit to

cool. Reduce amperage or voltage, or duty

cycle before welding.

NOTICE – Exceeding duty cycle can damage

machine or torch and void warranty.

0

10 60 100

150

200

250

Output Current (A)

300

30

TIG

247219-B

STICK

Rated Duty Cycle (%)

Overheating

0

15

A or V

OR

Reduce Duty Cycle

Minutes

4-9. Static Characteristics

The static (output) characteristics of the welding power source can be described as drooping during the SMAW and GTAW processes. Static

characteristics are also affected by control settings (including software), electrode, shielding gas, weldment material, and other factors. Contact

the factory for specific information on the static characteristics of the welding power source.

4-10. Environmental Specifications

A. IP Rating

IP Rating

IP23

This equipment is designed for outdoor use.

B. Temperature Specifications

Operating Temperature Range* Storage/Transportation Temperature Range

14 to 104°F (-10 to 40°C) -4 to 131°F (-20 to 55°C)

*Output is derated at temperatures above 104°F (40°C).

Loading...

Loading...