OM-284794 Page 36

F

Complete Parts List is available at www.MillerWelds.com

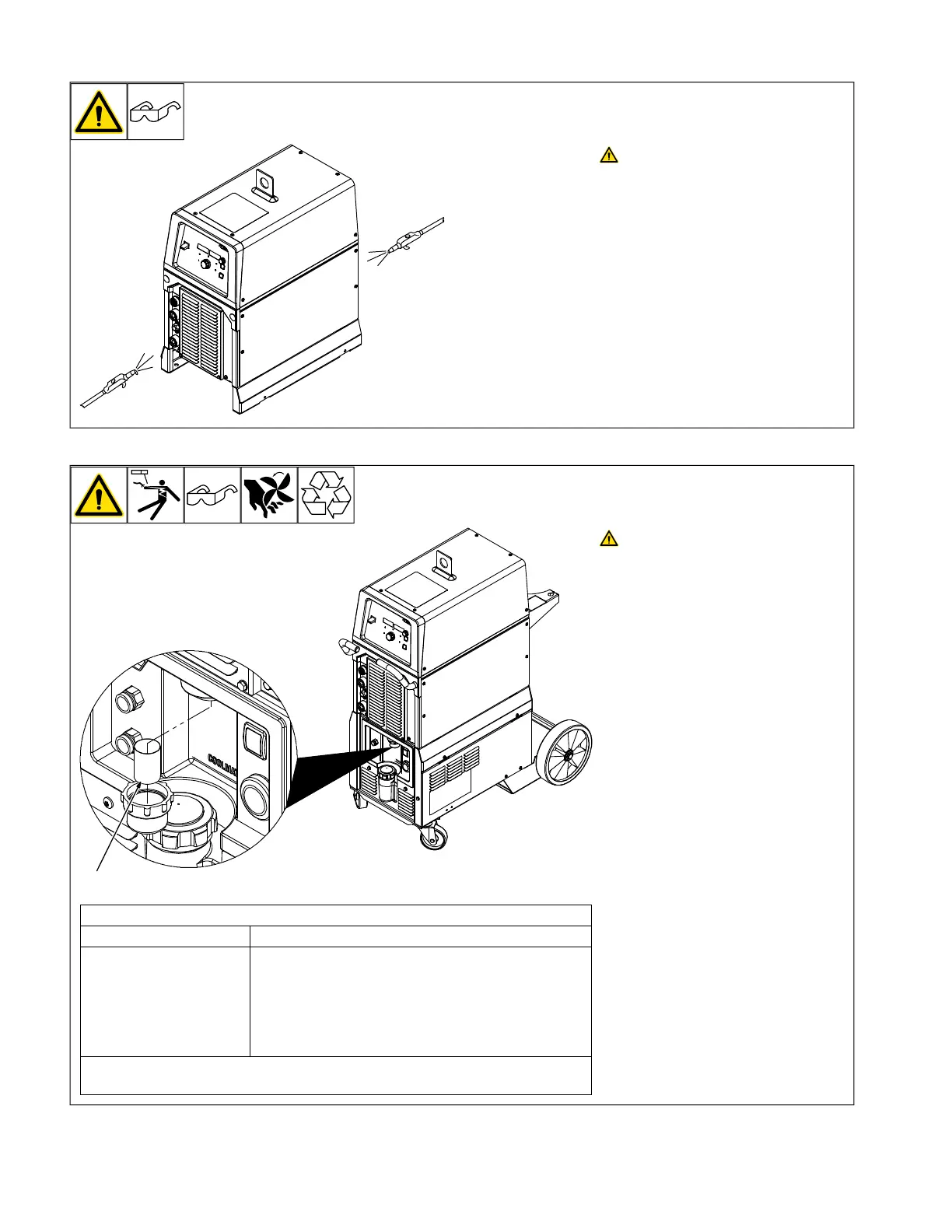

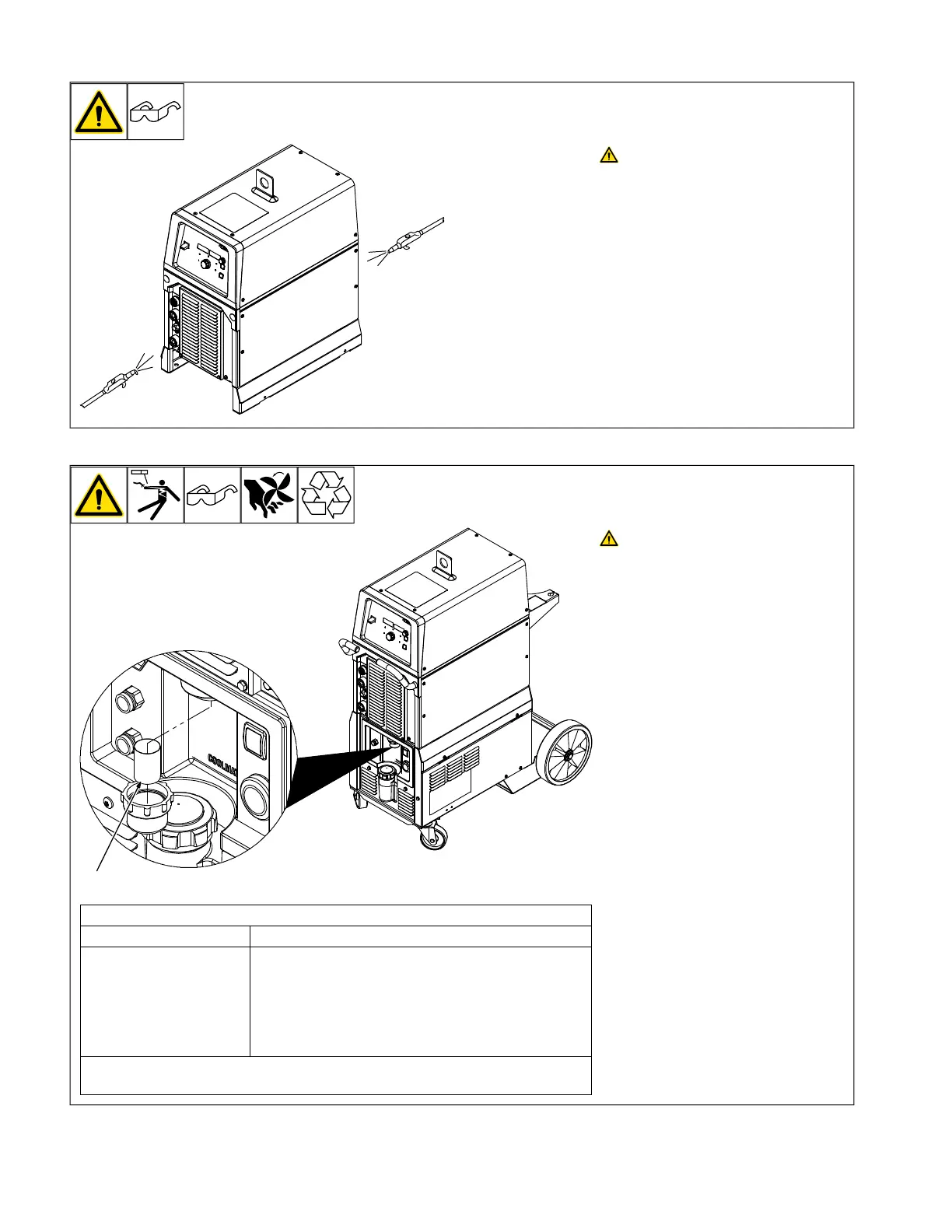

8-2. Blowing Out Inside Of Unit

Do not remove case when blowing

out inside of unit.

To blow out unit, direct airflow through front

and back louvers as shown.

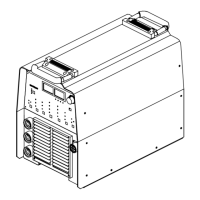

8-3. Coolant Maintenance

Coolant Specifications

Application GTAW or where HF (high frequency current) is used

Coolant

(3 gal)

Low Conductivity Coolant 043810

l 50/50 solution

l Protects to –37°F

(–38°C)

l Resists algae growth

Distilled or dionized water okay above 32°F (0°C)

NOTICE – Use of any coolant other than those listed in the table voids the warranty on any

parts that come in contact with the coolant (pump, radiator, etc.).

Disconnect input power before

maintaining.

1 Coolant Filter

Unscrew housing to clean filter.

Changing coolant: Drain coolant by tipping

unit to the front, or use suction pump. Fill

with clean water and run for 10 minutes.

Drain and refill with coolant.

F

If replacing hoses, use hoses compati-

ble with ethylene glycol, such as

Buna-N, Neoprene, or Hypalon. Oxy-

acetylene hoses are not compatible

with any product containing ethylene

glycol.

Loading...

Loading...