OM-284794 Page 31

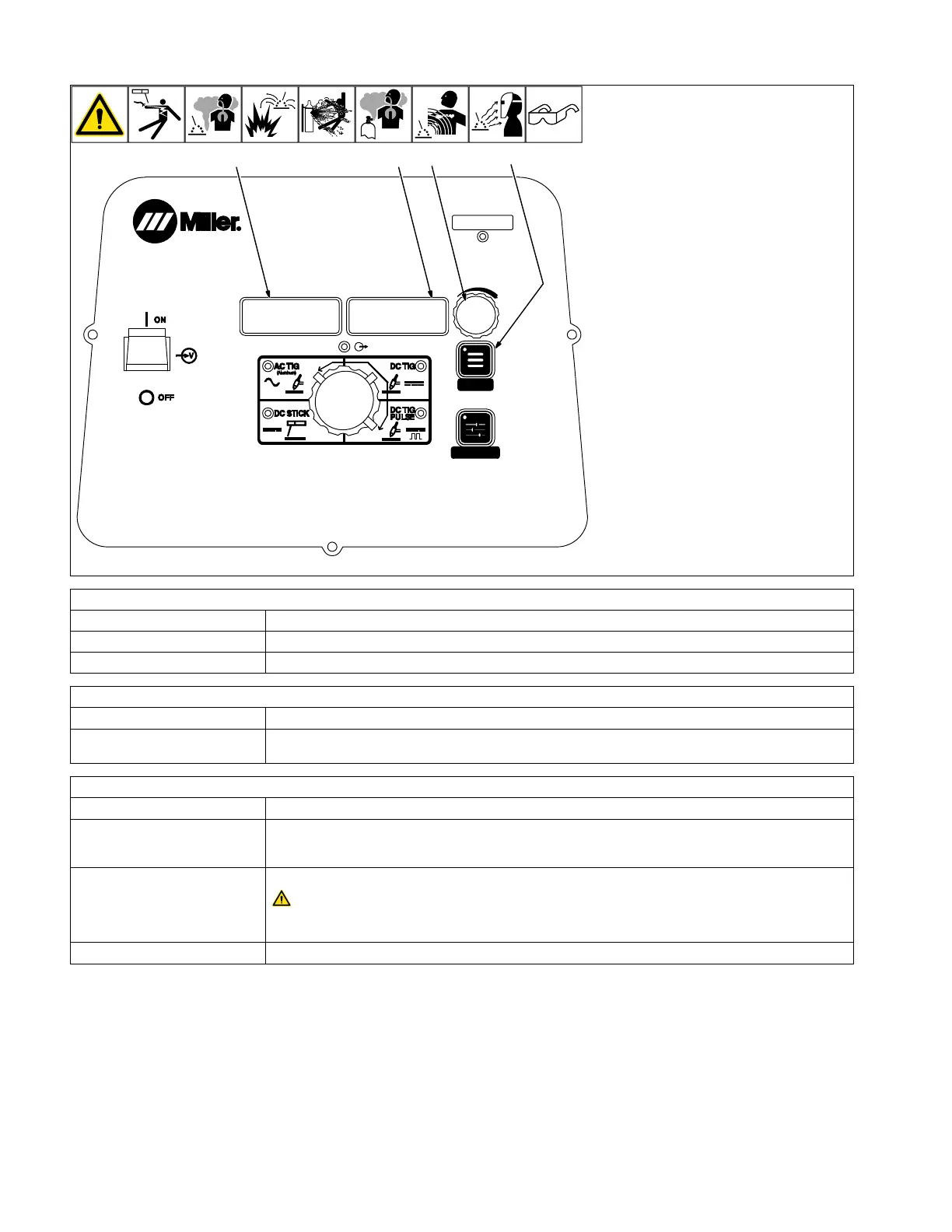

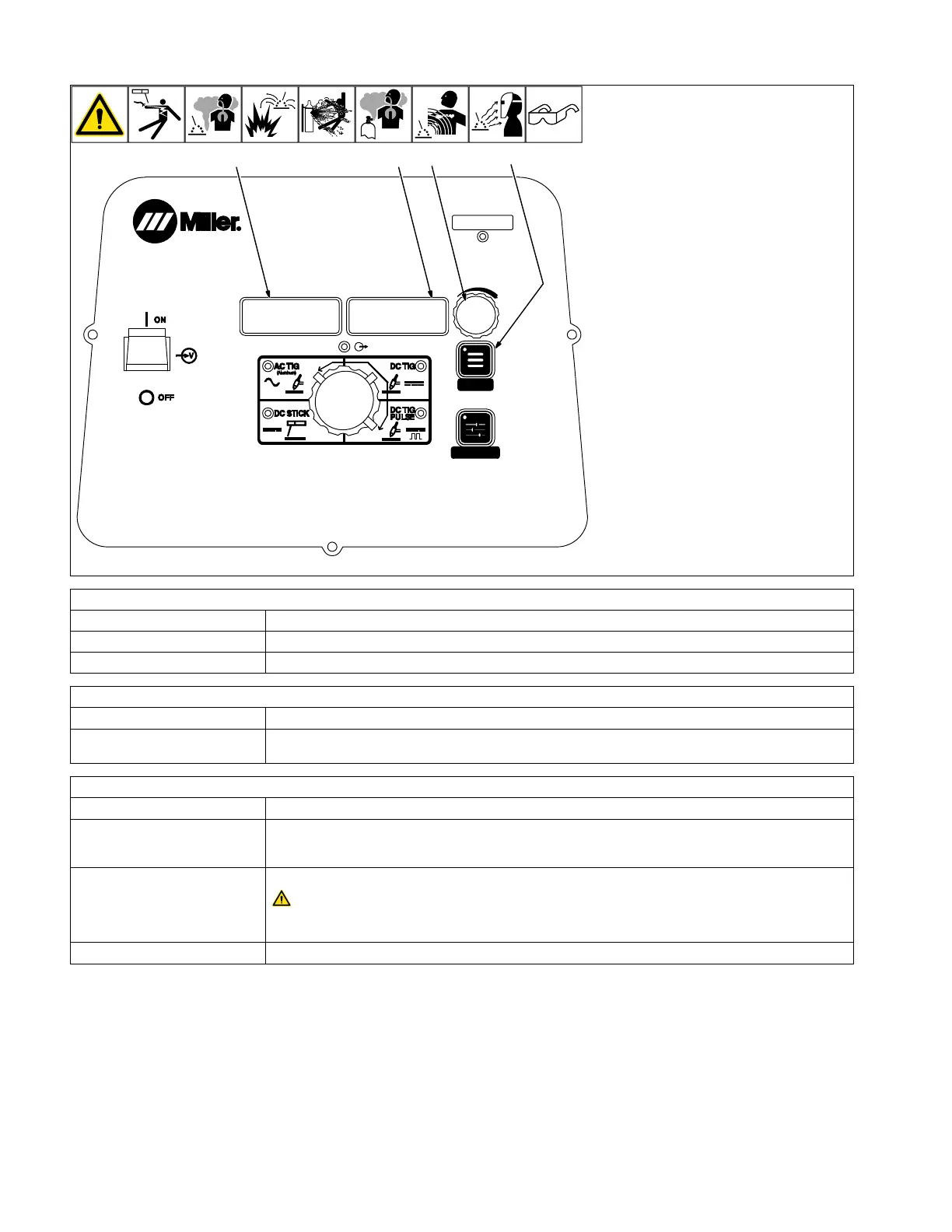

6-5. Accessing User Menu: AC/DC TIG And DC TIG Pulse

MENU

PRO-SET

MENU

USER

1

2

3

4

USER

280539-B

1 Menu Button

Press and hold Menu button for approxi-

mately two seconds until USER MENU ap-

pears to access machine configuration

menus. Press Menu button to cycle through

parameters that can be set.

2 Parameter Display

3 Setting Display

4 Amperage Adjustment Control

Rotate Amperage Adjustment control to ad-

just parameter setting.

F

To exit menu, press and hold Menu but-

ton until Menu Off is displayed.

Arc Starting Method Selection

Parameter/Setting Display Description

[STRT] [HF] High Frequency is a non-contact starting method (see Section 13-1).

[STRT] [LIFT] Lift Arc is a contact starting method (see Section 13-1).

Tungsten Diameter Selection

Parameter/Setting Display Description

[TUNG] [3/32] Each tungsten size has preset starting parameters specific to that diameter for optimized starting. Range

is 0.040 in.−1/8 in. or 1.0 mm−4.0 mm.

Trigger Mode Selection

Parameter/Setting Display Description

[RMT] [STD] Typically used with a remote foot or hand control. RMT STD requires a maintained contact closure to ena-

ble weld output. Amperage can be controlled with a remote potentiometer, or it can be set at the control

panel.

[OUT] [ON] Output on. (Lift Only)

Weld output terminals are energized at all times when displays read [OUT] [ON].

No remote control or trigger required. Amperage can be controlled at the control panel or with a remote

potentiometer. Blue output on LED illuminates to indicate output is on.

[PRE] [0.2T] Preflow Time: Controls length of time gas flows prior to arc start. Range is OFF-25T (seconds).

Loading...

Loading...