OM-284794 Page 21

F

Complete Parts List is available at www.MillerWelds.com

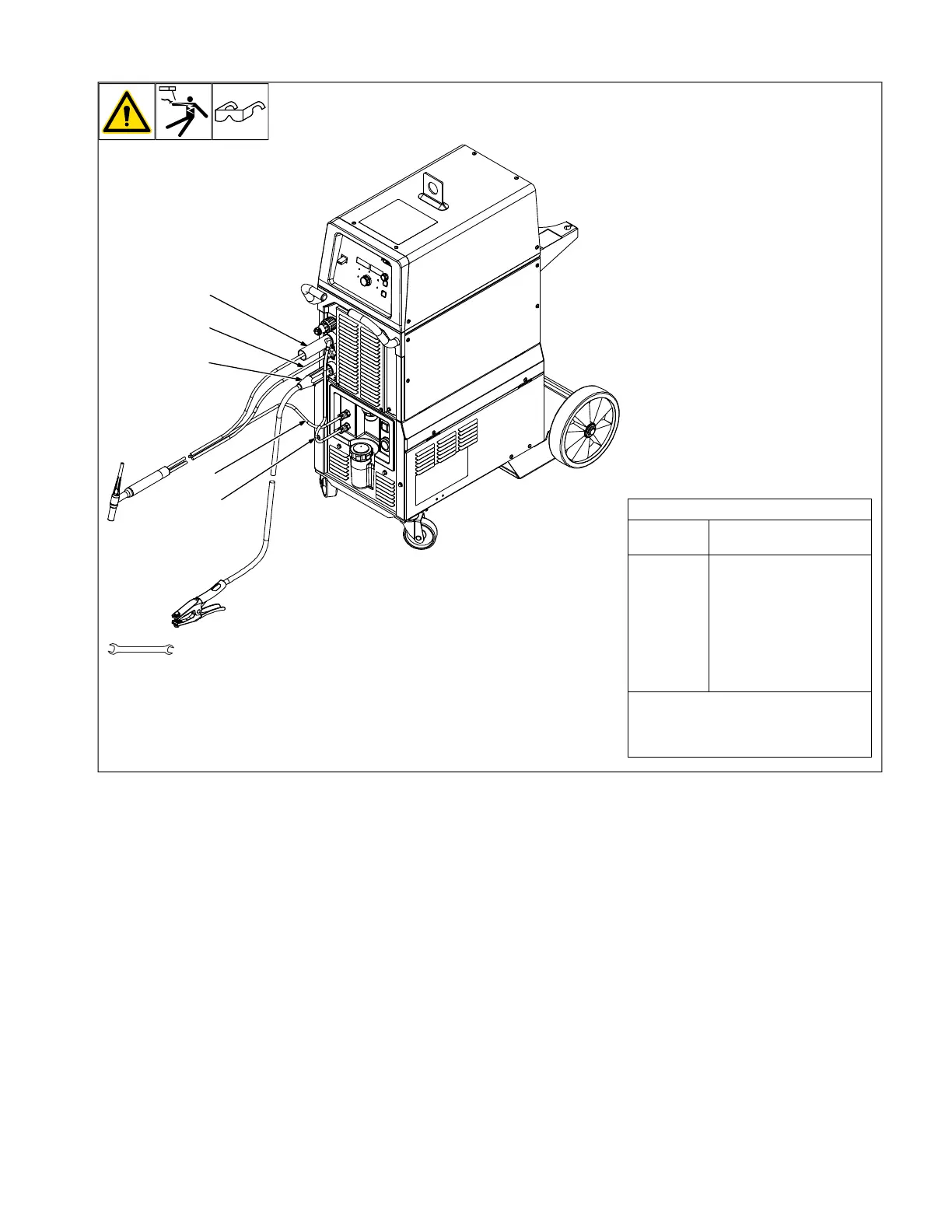

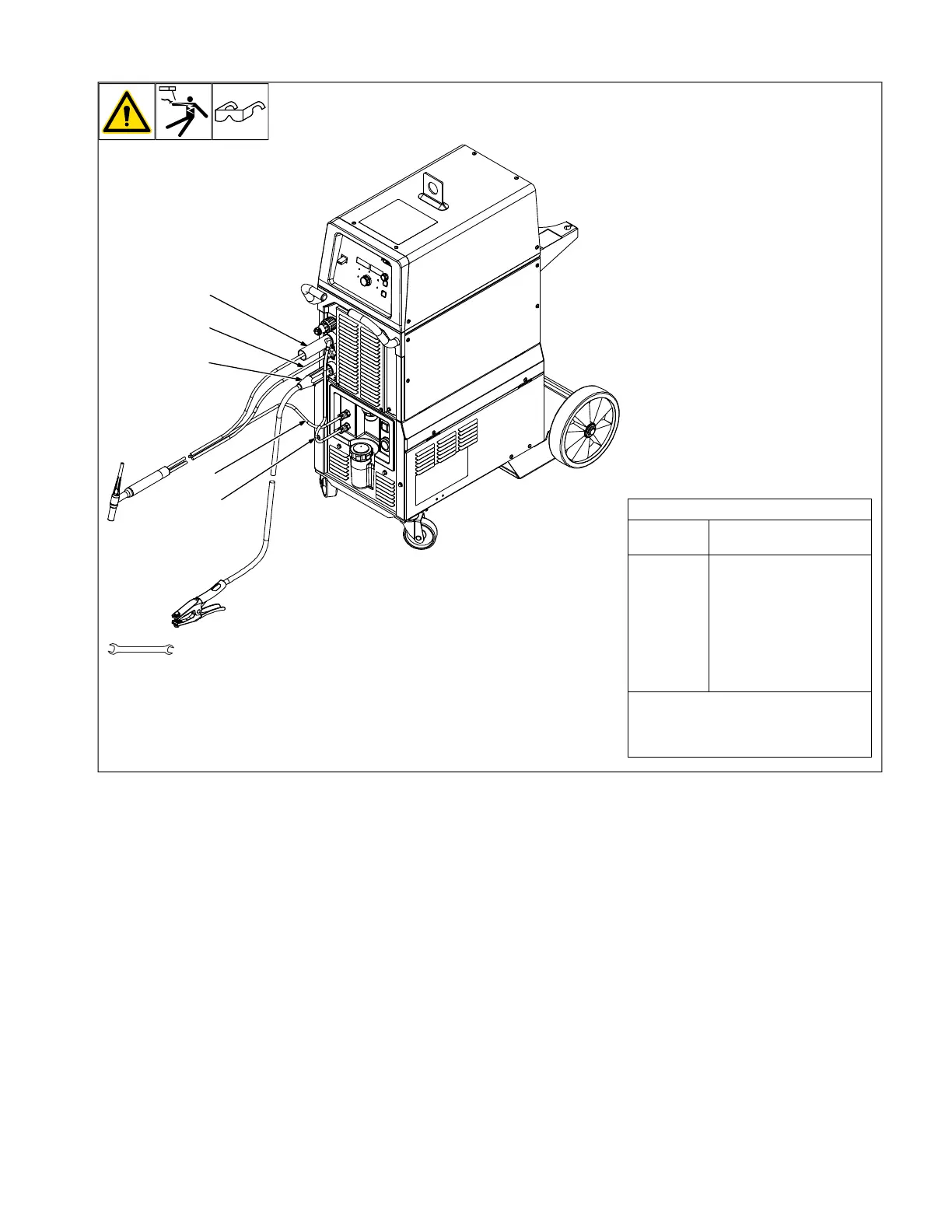

5-4. Cooler Connections

OM-222 Page 1

allen_wrench

NGO’s

tools/

flathead philips head wrench

pliers

knife

heavy-duty workclamp light-duty workclamp wirecutter frontcutter

allen_set

needlenose

steelbrush nutdriver

chippinghammer

solderiron

stripcrimp

drill

torque wrench

socket wrench

hammer awl file

crimper

paintbrush

feelergauge flashlight ruler

toothbrush

greasegun

qtip (swab)

vicegrip

handream

punch

filterwrench

strapwrench

airgun

solvent pinextractor eprompuller pipewrench

torque screwdriver

crescent wrench

11/16 in.

F

Cart and cooler are optional

equipment.

1 Electrode Weld Output Terminal

Connect TIG torch to this terminal.

2 Gas Out Connection

Connect TIG torch gas hose to gas out

fitting.

3 Work Weld Output Terminal

Connect work lead to this terminal.

4 Water-Out (To Torch) Connection

Connect torch water supply (blue) hose to

the coolers water-out connection.

5 Water-In (From Torch) Connection

Connect torch water return (red) hose to the

coolers water-in connection.

Coolant Specifications

Application GTAW or where HF (high

frequency current) is used

Coolant

(3 gal)

Low Conductivity Coolant

043810

l 50/50 solution

l Protects to –37°F

(–38°C)

l Resists algae growth

Distilled or dionized water

okay above 32°F (0°C)

NOTICE – Use of any coolant other than

those listed in the table voids the warranty

on any parts that come in contact with the

coolant (pump, radiator, etc.).

Loading...

Loading...