OM-284794 Page 41

SECTION 11 – HIGH FREQUENCY

11-1. Welding Processes Requiring High Frequency

OM-

SECTION 1 HIGH FREQUENCY

1

TIG

S-0694

13

9

8

7

1

2

4 5 6

3

10

11, 12

14

1 High-Frequency Voltage

TIG – helps arc jump air gap between torch

and workpiece and/or stabilize the arc.

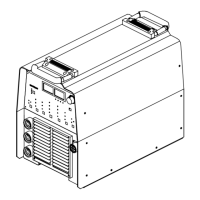

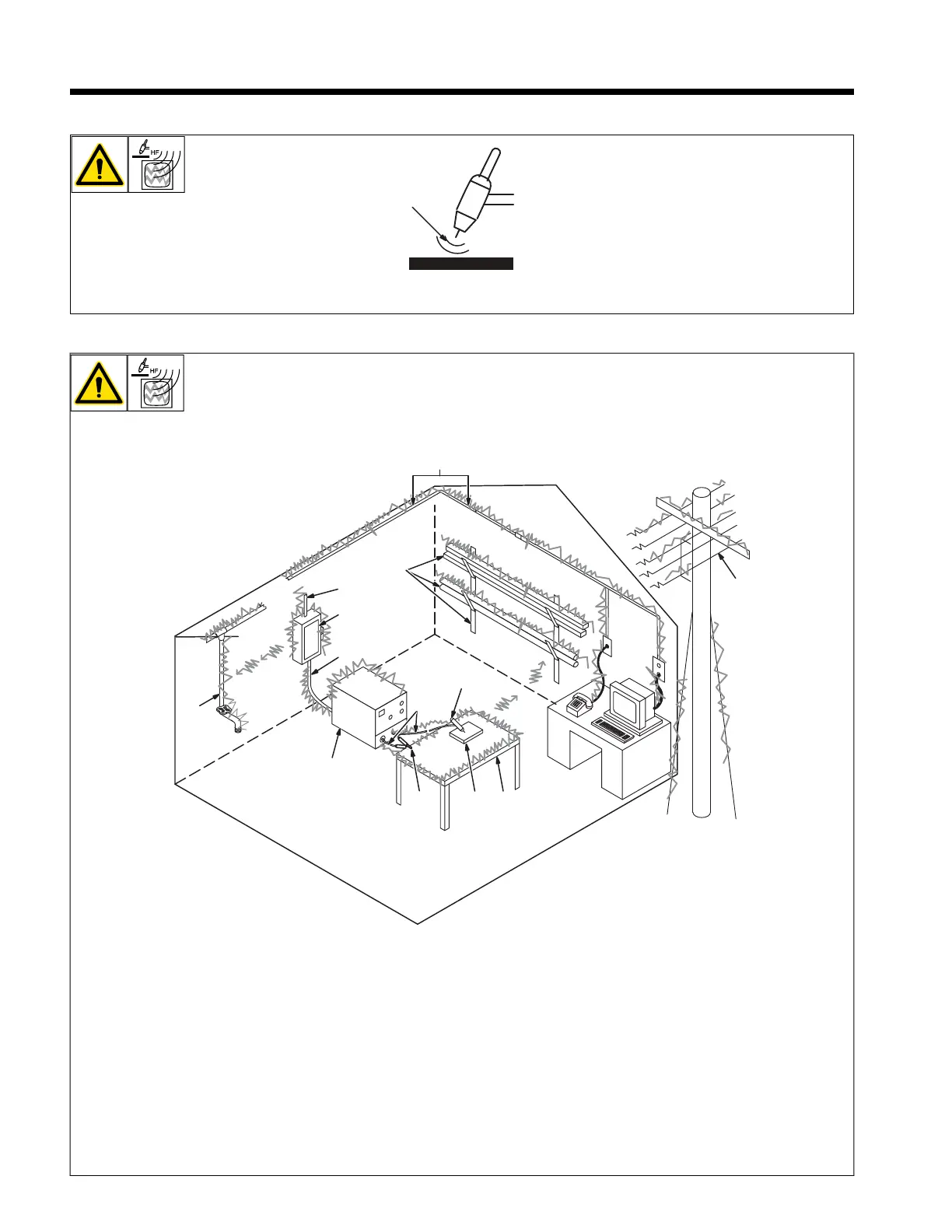

11-2. Installation Showing Possible Sources Of HF Interference

Best Practices Not Followed

OM-

SECTION 1 HIGH FREQUENCY

1

TIG

S-0694

13

9

8

7

1

2

4 5 6

3

10

11, 12

14

Sources of Direct High Frequency

Radiation

1 High-Frequency Source (welding power

source with built-in HF or separate HF

unit)

2 Weld Cables

3 Torch

4 Work Clamp

5 Workpiece

6 Work Table

Sources of Conduction of High

Frequency

7 Input Power Cable

8 Line Disconnect Device

9 Input Supply Wiring

Sources of Reradiation of High

Frequency

10 Ungrounded Metal Objects

11 Lighting

12 Wiring

13 Water Pipes And Fixtures

14 External Phone And Power Lines

Loading...

Loading...