OM-284794 Page 35

F

Complete Parts List is available at www.MillerWelds.com

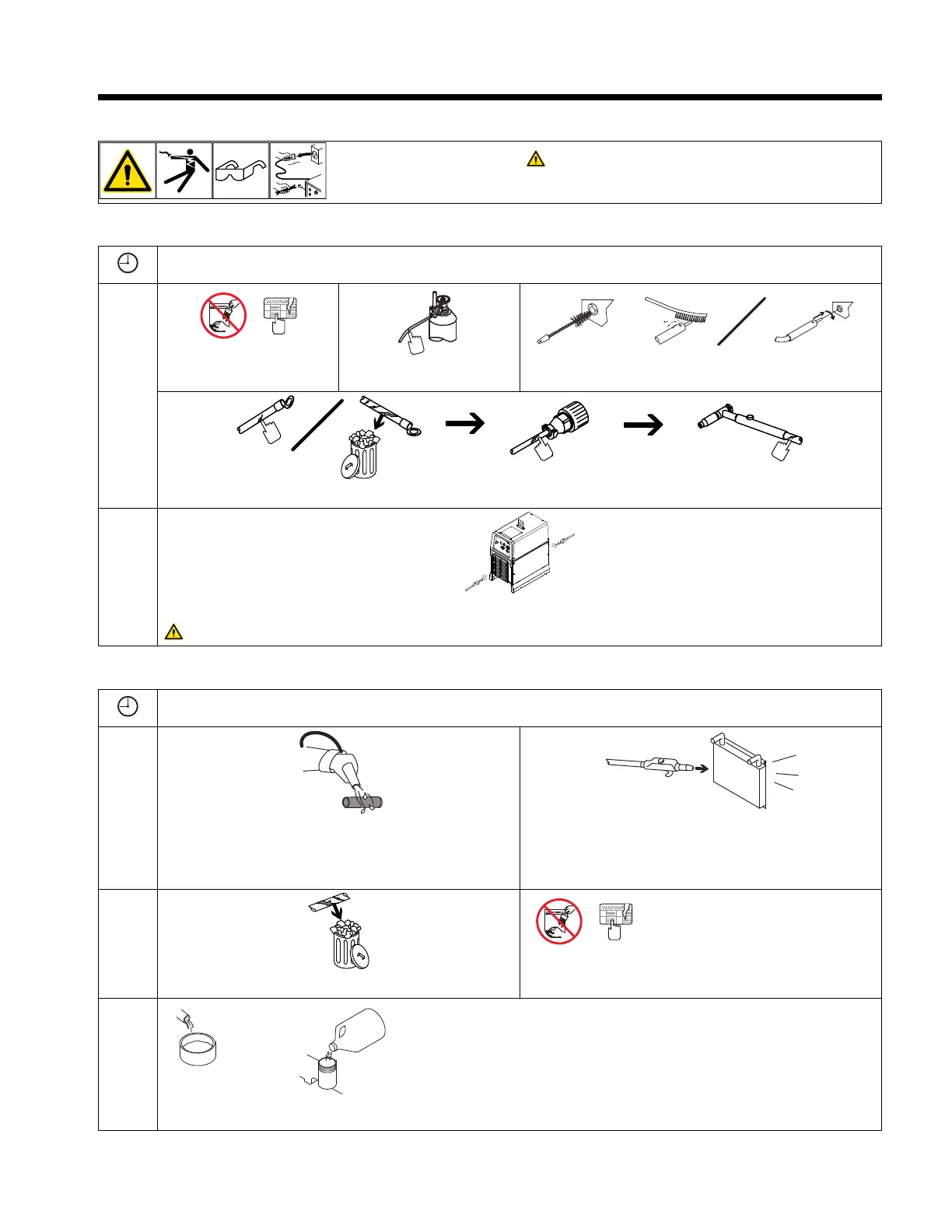

SECTION 8 – MAINTENANCE AND TROUBLESHOOTING

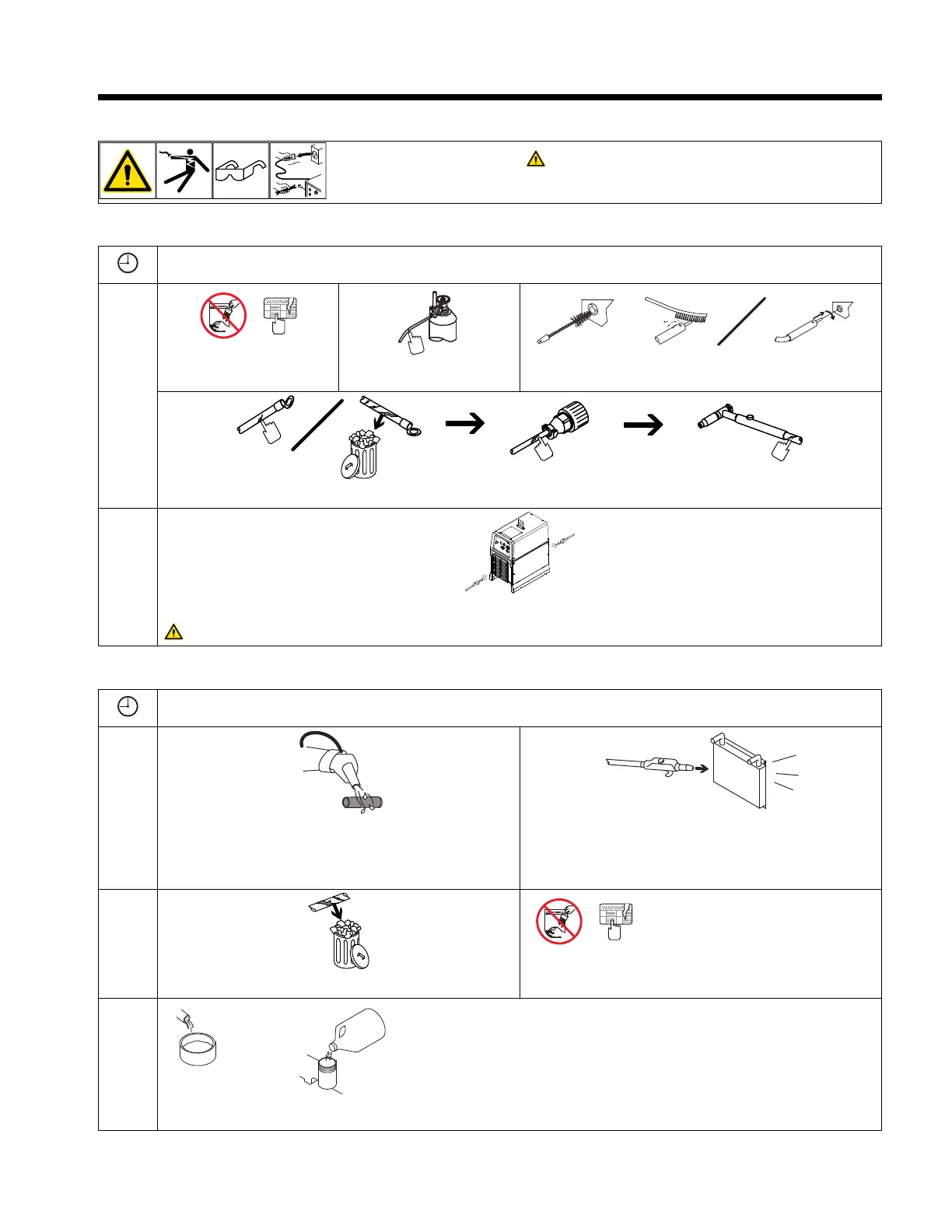

8-1. Routine Maintenance

Disconnect power before maintaining.

F

Maintain more often during severe conditions.

A. Welding Power Source

ü = Check ◇ = Change m = Clean ¶ = Replace

Every 3

Months

A complete Parts List is available at www.MillerWelds.com

SECTION 6 MAINTENANCE AND TROUBLESHOOTING

Every

3

Months

Weld Terminals

Labels

Every

3

Months

6-1. Blowing Out Inside of Unit

804746-B

A complete Parts List is available at www.MillerWelds.com

OM-231242 Page 29

SECTION 17 MAINTENANCE & TROUBLESHOOTING

17-1. Routine Maintenance

Every

3

Months

Replace Cracked

Torch Body

Repair Or Replace

Cracked Cables And

Cords

Clean

And

Tighten Weld

Connections

ü ¶ Labels ü ¶ Gas Hoses ü m Clean And Tighten Weld Connections

ü ¶ Cables And Cords

Every 6

Months

m During heavy service, clean monthly.

Do not remove case when blowing out inside of unit

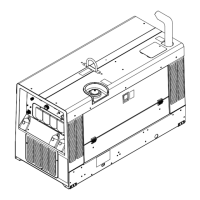

B. Optional Cooler

ü = Check ◇ = Change m = Clean ¶ = Replace

Every 3

Months

A complete Parts List is available at www.MillerWelds.com

OM-270536 Page 42

SECTION 9 MAINTENANCE AND TROUBLESHOOTING

Every

6

Months

:During heavy service, clean monthly.

!

Do not remove case when blowing out inside of unit

9-1.Optional Cooler

= Check = Change = Clean ∆ = Repair = Replace

* To be done by Factory Authorized Service Agent

Every

3

Months

Coolant Strainer,

durning heavy service,

clean more frequently.

Blow out heat exchanger fins.

Check coolant level. Top off with

distilled or deionized water if necessary.

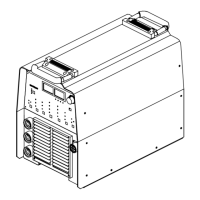

9-2. Blowing Out Inside of Unit

805497-A

!

Do not remove case when

blowing out inside of unit.

To blow out unit, direct airflow

through front and back louvers as

shown.

A complete Parts List is available at www.MillerWelds.com

OM-270536 Page 42

SECTION 9 MAINTENANCE AND TROUBLESHOOTING

Every

6

Months

:During heavy service, clean monthly.

!

Do not remove case when blowing out inside of unit

9-1.Optional Cooler

= Check = Change = Clean ∆ = Repair = Replace

* To be done by Factory Authorized Service Agent

Every

3

Months

Coolant Strainer,

durning heavy service,

clean

more frequently.

Blow out heat exchanger fins.

Check coolant level. Top off with

9-2. Blowing Out Inside of Unit

805497-A

!

Do not remove case when

blowing out insid

e of unit.

To blow out unit, direct airflow

through front and back louvers as

shown.

m Coolant strainer; during heavy service, clean more

frequently.

m Blow out heat exchanger fins.

ü Check coolant level. Top off with distilled or deionized water if

necessary.

Every 6

Months

ü ¶ Hoses ü¶ Labels

Every

12

Months

A complete Parts List is available at www.MillerWelds.com

OM-270536 Page 65

SECTION 12 MAINTENANCE AND TROUBLESHOOTING

12-1. Routine Maintenance

Maintain more often during severe conditions.

! Disconnect power before maintaining.

A. Welding Power Source

= Check = Change = Clean ∆ = Repair = Replace

* To be done by Factory Authorized Service Agent

Every

3

Months

Labels Gas Hoses

Every

3

Months

∆ Cables And Cords

Every

6

Months

:During heavy service, clean monthly.

! Do not remove case when blowing out inside of unit

B. Optional Cooler

= Check = Change = Clean ∆ = Repair = Replace

* To be done by Factory Authorized Service Agent

Every

3

Months

Coolant Strainer,

durning heavy service,

clean more frequently.

Blow out heat exchanger fins.

Check coolant level. Top off with

distilled or deionized water if necessary.

Every

6

Months

Hoses

Labels

Every

12

Months

◇ Coolant

Loading...

Loading...