Maintenance and Testing Schedule Maintenance

10 - 4 BP10 Operator’s Manual

10.5 Maintenance and Testing Schedule

The following maintenance and tests, except for visual inspection, power on test, and

battery check, shall be carried out by the service personnel only. Contact your service

personnel if any maintenance is required. Make sure to clean and disinfect the

equipment before any test and maintenance.

10.6 Power-On Test

Verify that the startup logo screen displays and a beep sounds after power on the device.

10.7 Checking the Device Information

To view the information about the device copyright information, serial number, system

software, hardware and MPAN version, you can select System Info in the main menu.

10.8 NIBP Leakage and Pressure Tests

The NIBP leakage and pressure tests checks the integrity of the system and of the valve.

Contact your service personnel to perform NIBP leakage and pressure test.

10.9 Electrical Safety Test

The electrical safety test aims to detect abnormalities that, if undetected, could prove

dangerous to either the patient or the operator. Contact your service personnel to

perform the electrical safety test.

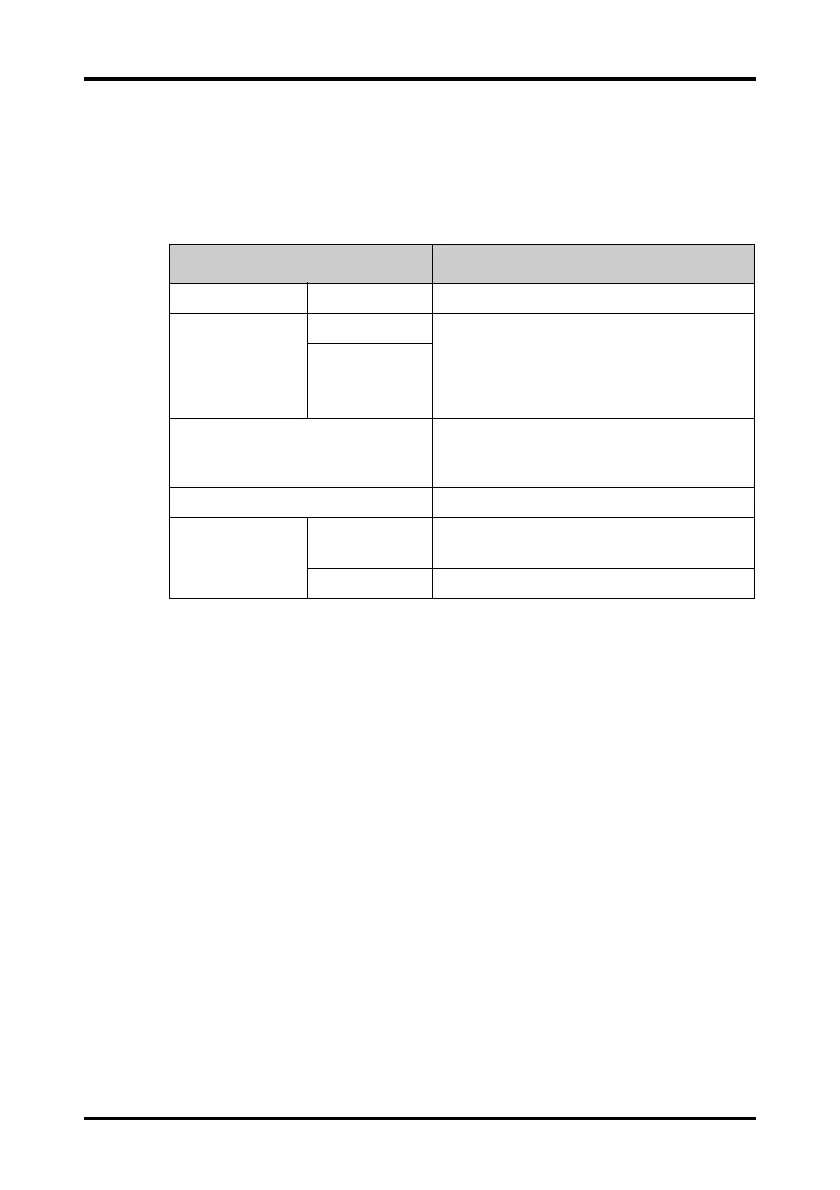

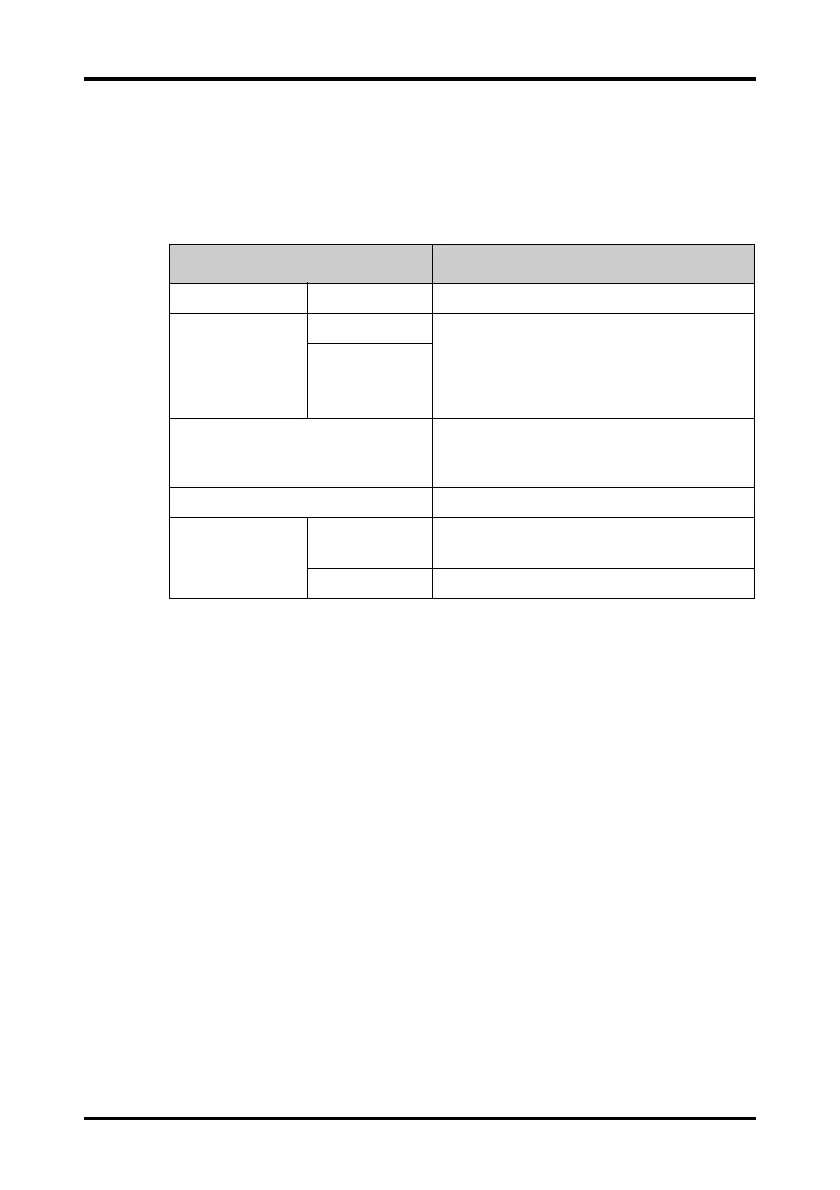

Check/Maintenance Item Recommended Frequency

Visual inspection When first installed or reinstalled.

NIBP test Pressure check 1. If the user suspects that the measurement is

incorrect.

2. Following any repairs or replacement of rele-

vant module.

3. Once a year.

Leakage test

Power-on test 1. When first installed or reinstalled.

2. Following any maintenance or the replace-

ment of any main unit parts.

Electrical safety test At least once every two years or as needed.

Battery check Functionality test 1. When first installed.

2. Whenever the battery is replaced.

Performance test When the battery run time reduced significantly.

Loading...

Loading...