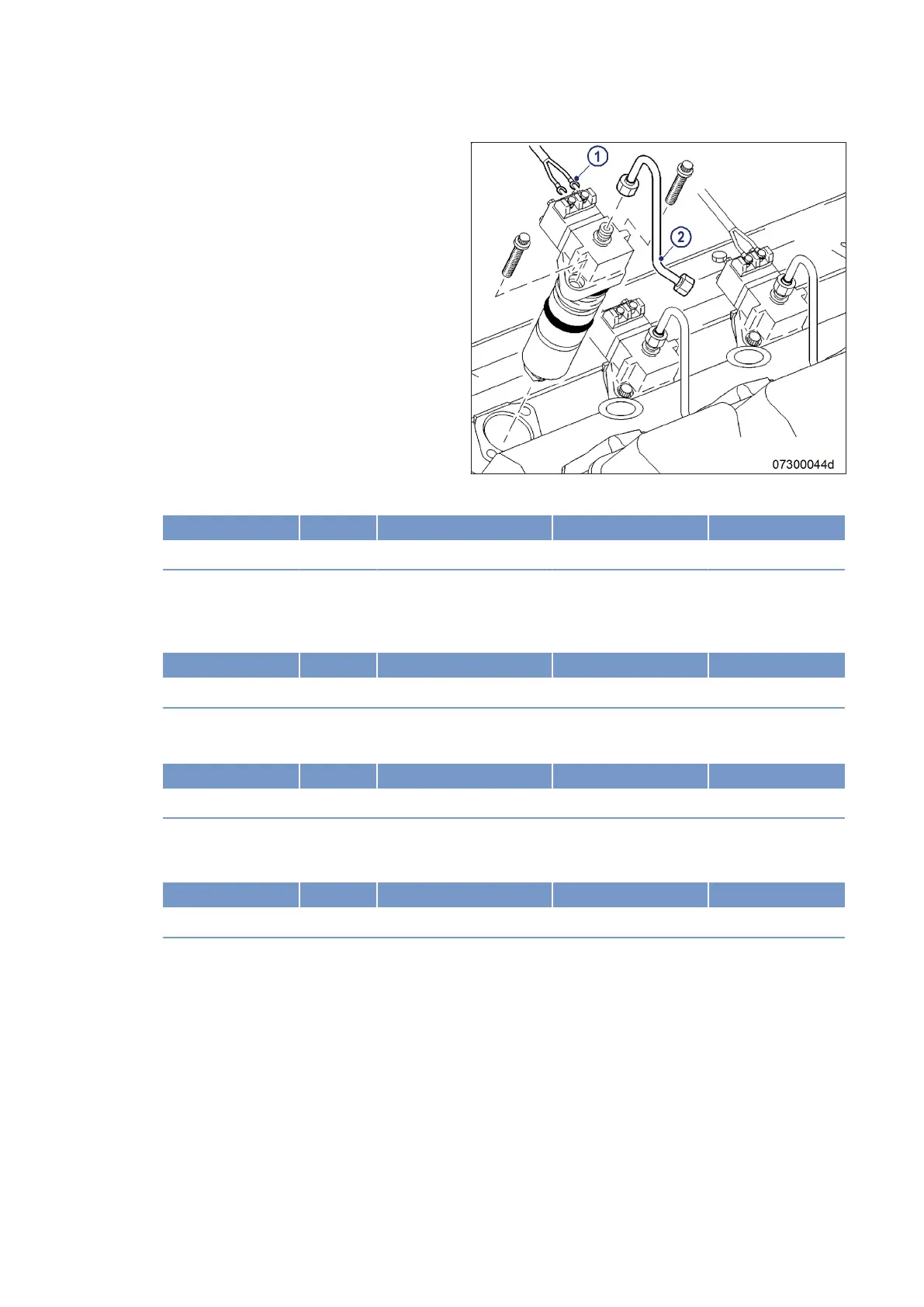

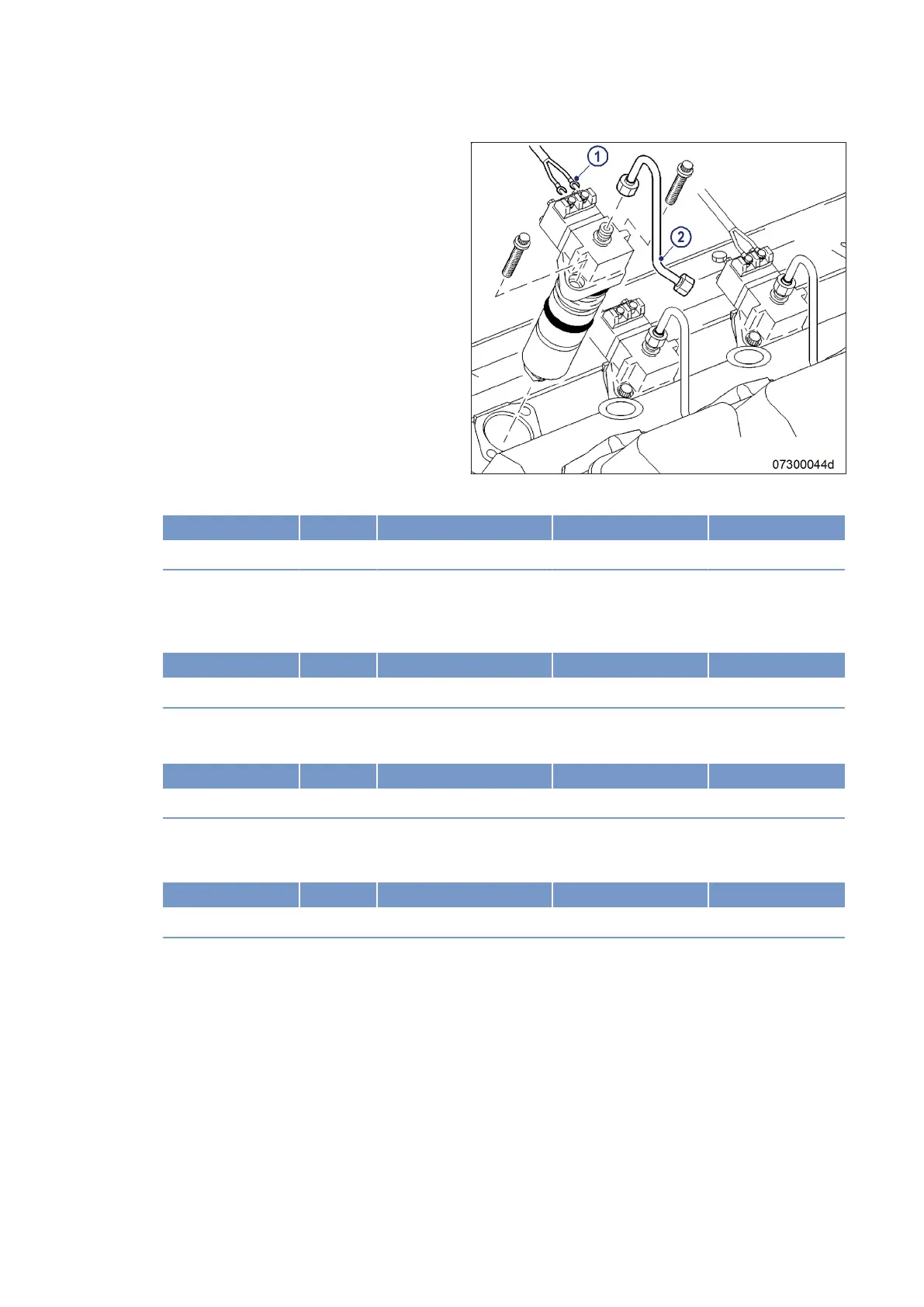

8. Install injection pump, observing marked in-

stallation position.

9. Install securing screws of injection pump and tighten to specified torque using a torque wrench.

Name Size Type Lubricant Value/Standard

Securing screw Tightening torque 60 Nm + 12 Nm

10. Install fuel line (2).

11. Tighten union nut on injection pump to specified torque using a torque wrench.

• Maximum permissible tightening torque: 35 Nm

Name Size Type Lubricant Value/Standard

Union nut Tightening torque 20 Nm + 5 Nm

12. Tighten union nut on pressure pipe neck to specified torque using a torque wrench.

• Maximum permissible tightening torque: 35 Nm

Name Size Type Lubricant Value/Standard

Union nut Tightening torque 20 Nm + 5 Nm

13. Install injection pump cabling (1).

14. Tighten screws to specified torque using a torque wrench.

Name Size Type Lubricant Value/Standard

Screw Tightening torque 1.0 Nm ± 0.2 Nm

Final steps

1. Remove engine barring tool (→ Page 146).

2. Clean mating faces on cylinder head and charge-air manifold.

3. Check gaskets for damage and replace them, if required.

4. Coat gaskets with assembly compound and place onto cylinder head.

5. Install charge-air pipes.

6. Install engine control system (→ Page 224).

7. Open fuel supply line upstream of fuel filter.

8. Vent fuel system (→ Page 170).

162 | Injection Pump / HP Pump |

MS150031/06E 2016-010

TIM-ID: 0000004579 - 008

Loading...

Loading...