FORM NO. 56043124 - Condor XL

™

- 17

MAINTENANCE

HYDRAULIC OIL

Open and prop the Engine Cover (3) to access the hydraulic oil reservoir. Remove the Fill Cap (44) from the tank and look to the bottom of the fi ller

screen. If the oil level is below the bottom of the fi ller screen, add 10W-30 motor oil until the bo ttom of the fi ller screen is covered. (The oil level

should not be higher than 1/2” (12.7mm) above the bottom of the fi ller screen.) Change and fl ush the oil if major contamination from a mechanical

failure occurs.

ENGINE MAINTENANCE

ENGINE OIL – GASOLINE / PETROL AND LPG

Check the engine oil level when the machine is parked on a level surface and the engine is cool. Change the engine oil after the fi rst 35 hours

of operation and every 150 hours after that. Use any SF or SG rated oil meeting API specifi cations and suited to seasonal temperatures. Refer

to the engine manufacturers’ service manuals for oil capacities and additional engine specifi cations. Replace the oil fi lter with every oil change.

TEMPERATURE RANGE OIL WEIGHT

Above 60° F (15° C) SAE 10W-30

Below 60° F (15° C) SAE 5W-30

ENGINE OIL – DIESEL

Check the engine oil level when the machine is parked on a level surface and the engine is cool. Change the engine oil after the fi rst 35 hours of

operation and every 150 hours after that. Use CF, CF-4 or CG-4 oil meeting API specifi cations and suited temperatures.

*Important: Reference the oil/fuel type note below for further diesel oil recommendations. Refer to the engine manufacturers’ service manuals for

oil capacities and additional engine specifi cations. Replace the oil fi lter with every oil change.

TEMPERATURE RANGE OIL WEIGHT

Above 77 °F (25 °C) SAE 30 or 10W-30

32 °F to 77 °F (0 °C to 25 °C) SAE 20 or 10W-30

Below 32 °F (0 °C) SAE 10W or 10W-30

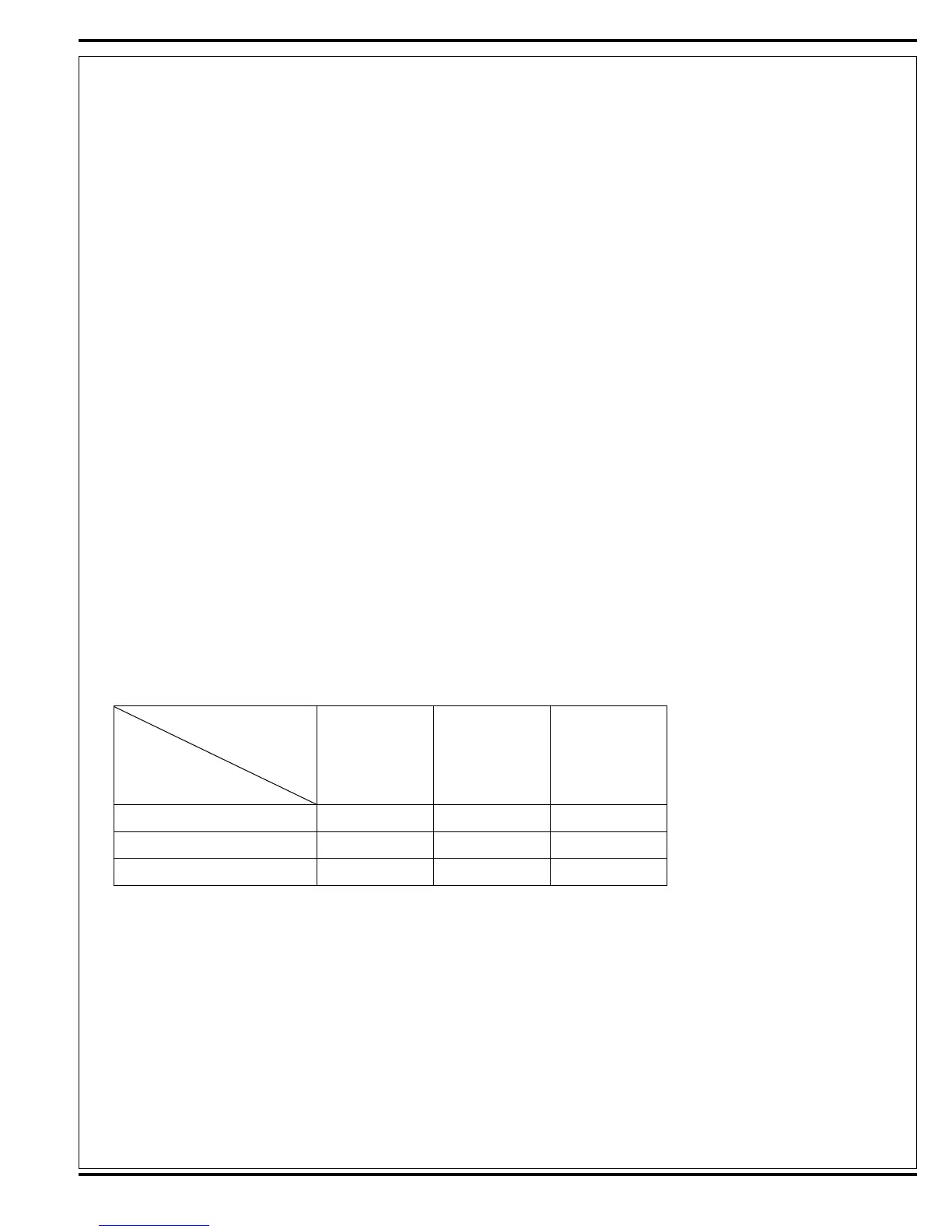

* Diesel Lubricating Oil Note:

With the emission control now in effect, the CF-4 and CG-4 lubricating oils have been developed for use with a low-sulfur fuel used in on-road vehicle

engines. When an off-road vehicle engine runs on a high-sulfur fuel, it is advisable to employ the CF, CD or CE lubricating oil with a high total

base number. If the CF-4 or CG-4 lubricating oil is used with a high-sulfur fuel, change the lubricating oil at shorter intervals.

Recommended lubricating oil when low-sulfur or high-sulfur fuel is employed

Fuel

Lubricating

Oil class

Low sulfur

(0.5 % ≥)

High sulfur Remarks

CF

OO

TBN ≥ 10

CF-4

OX

CG-4

OX

O : Recommended X : Not recommended

SPECIAL LIQUID PROPANE FUEL SYSTEM MAINTENANCE ON THE GM 1.6L ENGINE

Every 150 hours inspect and drain any oil buildup from the LP fuel system electronic pressure regulator (EPR). During the course of normal opera-

tion, oils or “heavy ends” may build inside the chambers of the propane regulator. These oils and heavy ends may be a result of poor fuel quality,

contamination of the fuel supply chain, or regional variation in the makeup of the fuel. If the oil buildup is signifi cant it can affect the function of the

fuel control system. Note: Reference the Tier 2 PSI 1.6l PFI certifi ed engine service manual, form # PSI1P6LPFI-A, and follow the procedure to

drain the EPR regulator.

Loading...

Loading...