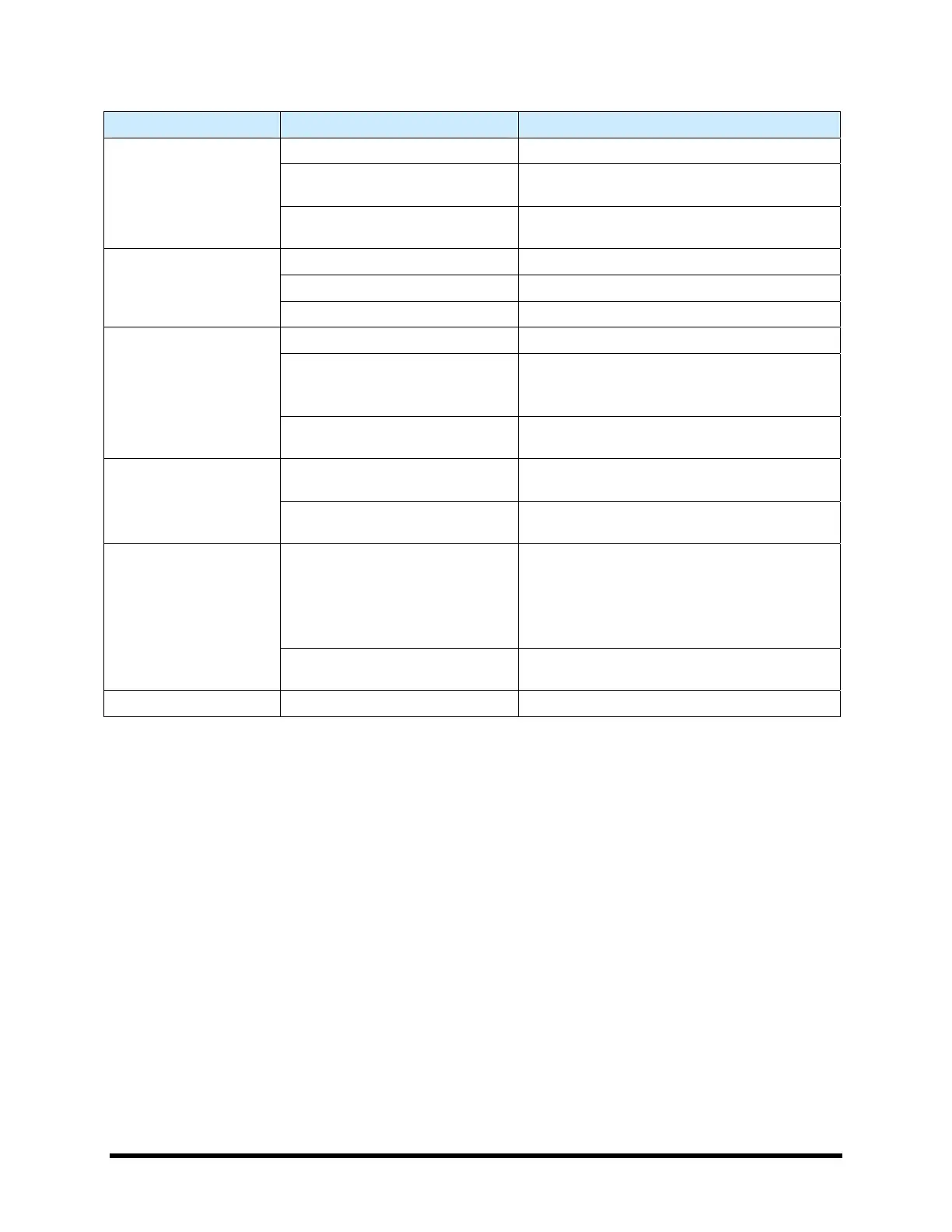

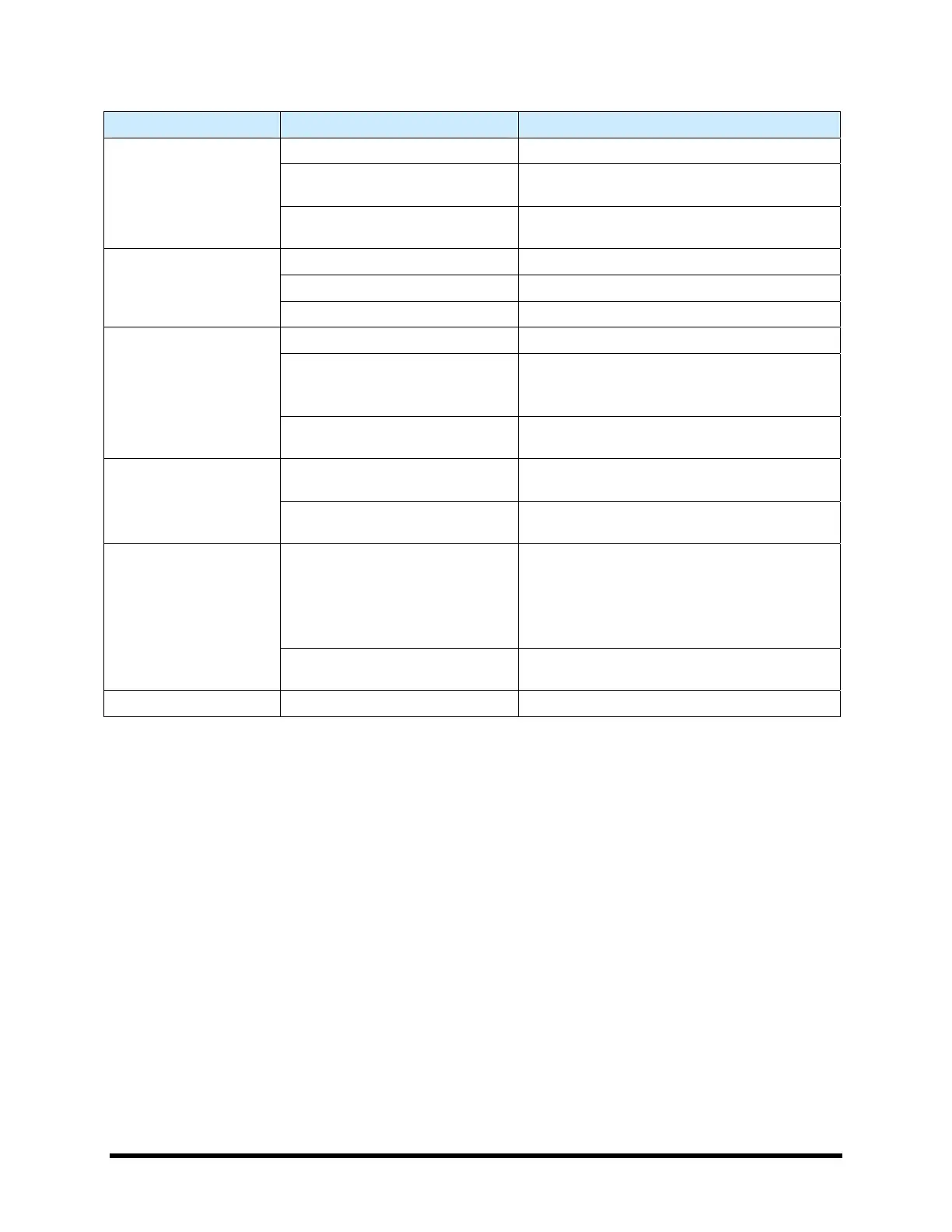

Troubleshooting 8-15

Table 8-13 Conveyor Troubleshooting (Continued)

Symptom Possible Cause Recovery

Workpiece or carrier is jammed Call a trained service technician.

SMEMA interface is not functioning

properly

Call a trained service technician.

Conveyor does not

transfer parts from

upstream to downstream

machines

Incorrect alignment of upstream or

downstream machine

The machines must be realigned. Call a trained

service technician.

Sensor is not active Call a trained service technician.

Sensor is dirty Clean sensors with a soft cloth or with blown air.

Board sensors not

sensing when board is

present

Sensor is out of adjustment Call a trained service technician.

Stop Pin is not receiving air Call a trained service technician.

Board Sensor is dirty, not active or

out of adjustment

Clean sensor.

If no improvement, call a trained service

technician.

Board will not index to

correct position

Gap between conveyor rails is too

narrow

Check conveyor width and readjust as

necessary.

Conveyor/Heater Controller has

no power

Verify that the AC power cable is connected to

the module and to the facility power source.

Conveyor does not move

at all (with Fluidmove

position controls)

Fuse is blown in Conveyor/Heater

Controller

See 9.10 Replacing Fuses.

Gap between conveyor rails is too

wide

1. Stop the dispensing program.

2. Realign the workpiece on the conveyor belt.

3. Use the Fluidmove position controls to

adjust the rail gap.

4. Restart the dispensing program.

Conveyor jams or does

not move

The carrier is bent

Stop the dispensing program and remove the

carrier.

Fails to find width Home The width “home” sensor has failed Call a trained service technician.

Loading...

Loading...