CHAPTER 14

WIDTH CHANGE PROCEDURE

45

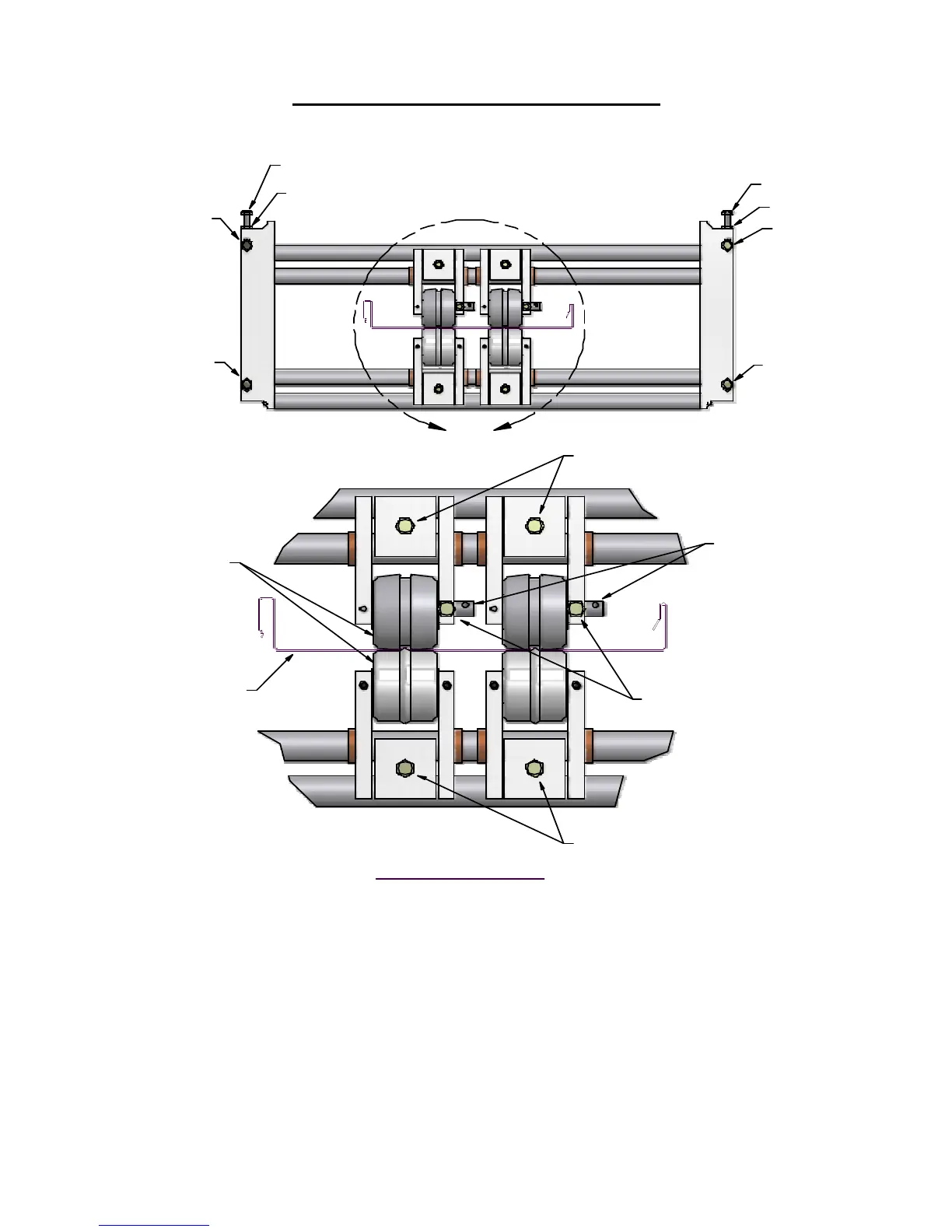

A

BO L T "A"

LOCK N UT

BOLT "B"

BOL T "B"

BOL T "A"

LOCK N UT

BO LT "B"

BOLT "B"

BOLT "D"

BOLT "D"

BOLT "C "

HOLE FOR

HEX WREN CH

PASS LIN E

SID ES FLU SH

DETAIL A

RR5 OPTION SHOW N

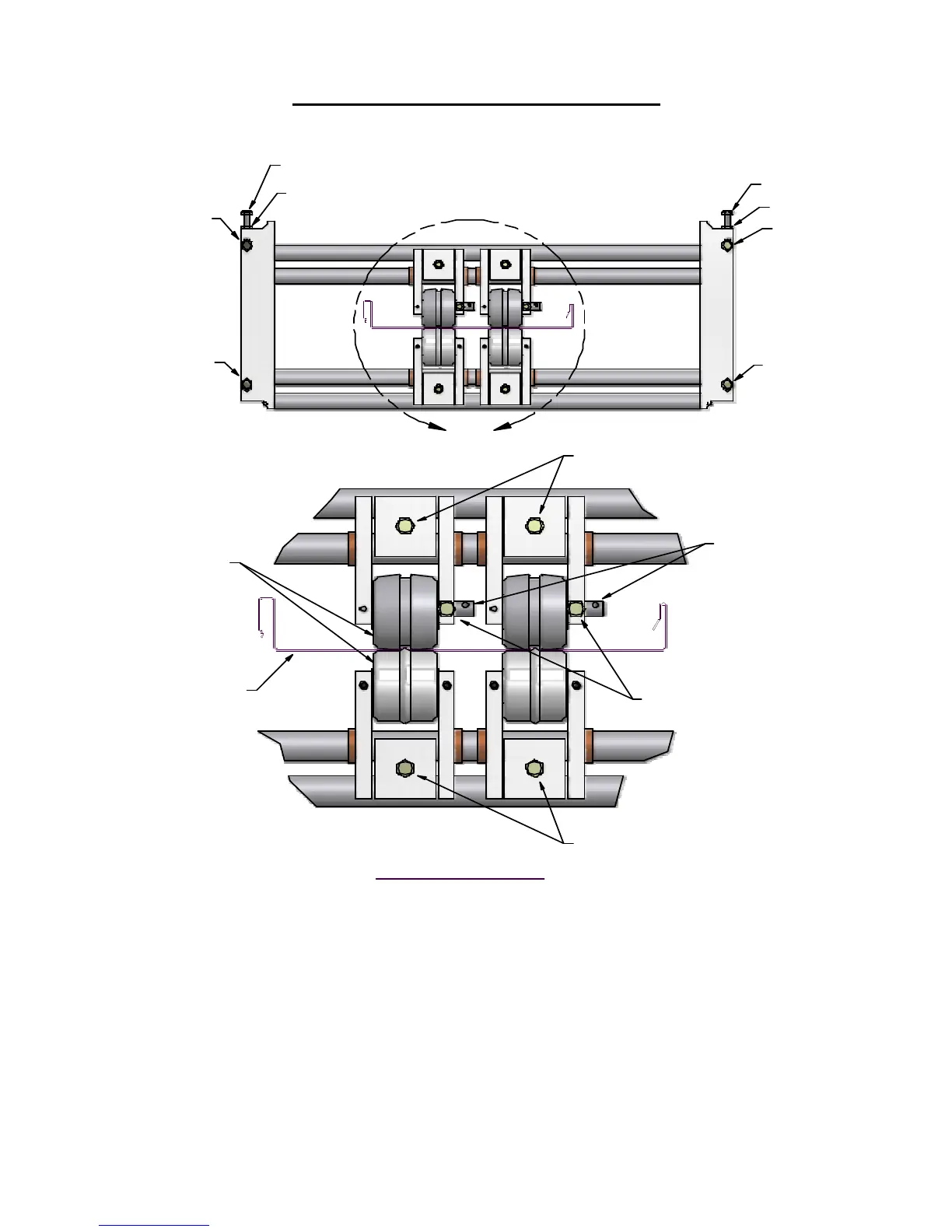

Figure 34: Bead Roller Width Change

11. Check the gap between the top and bottom bead rollers using a feeler gauge.

An approximate setting of 1½ times the material thickness is recommended.

This setting can be adjusted slightly in either direction according to

preference.

12. To set or change the gap between top and bottom beads, loosen the "C" bolt

on both top rollers (Figure 34).

13. Insert the correct feeler gage between one of the top and bottom rollers.

Locate the feeler gage on the flat of the roller next to the side plate of the

assembly.

Loading...

Loading...