CHAPTER 15

PROFILE CHANGEOVER PROCEDURE

62

30. Start the machine again and slowly jog the panel approximately 6” past the exit

die and stop. Again, TURN THE MACHINE OFF.

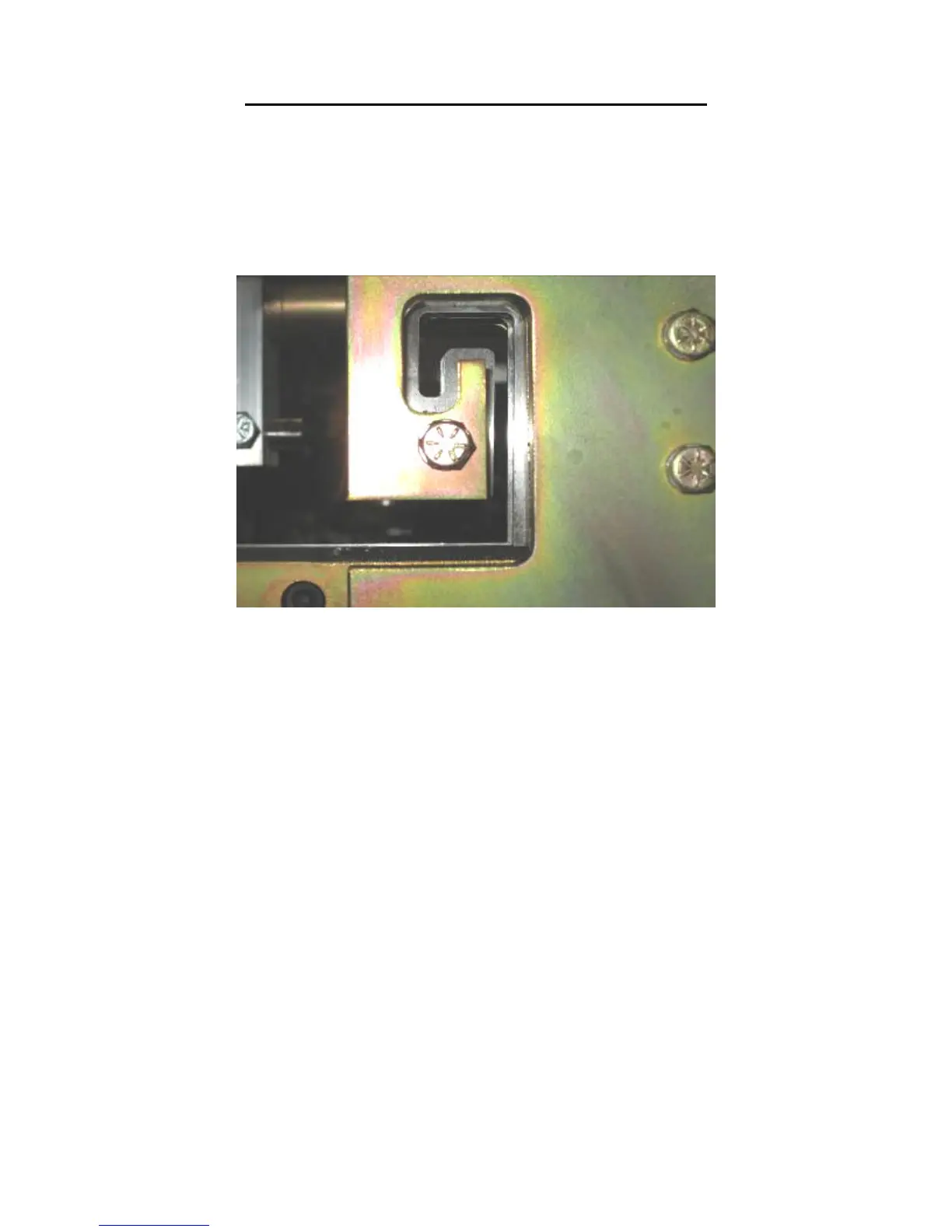

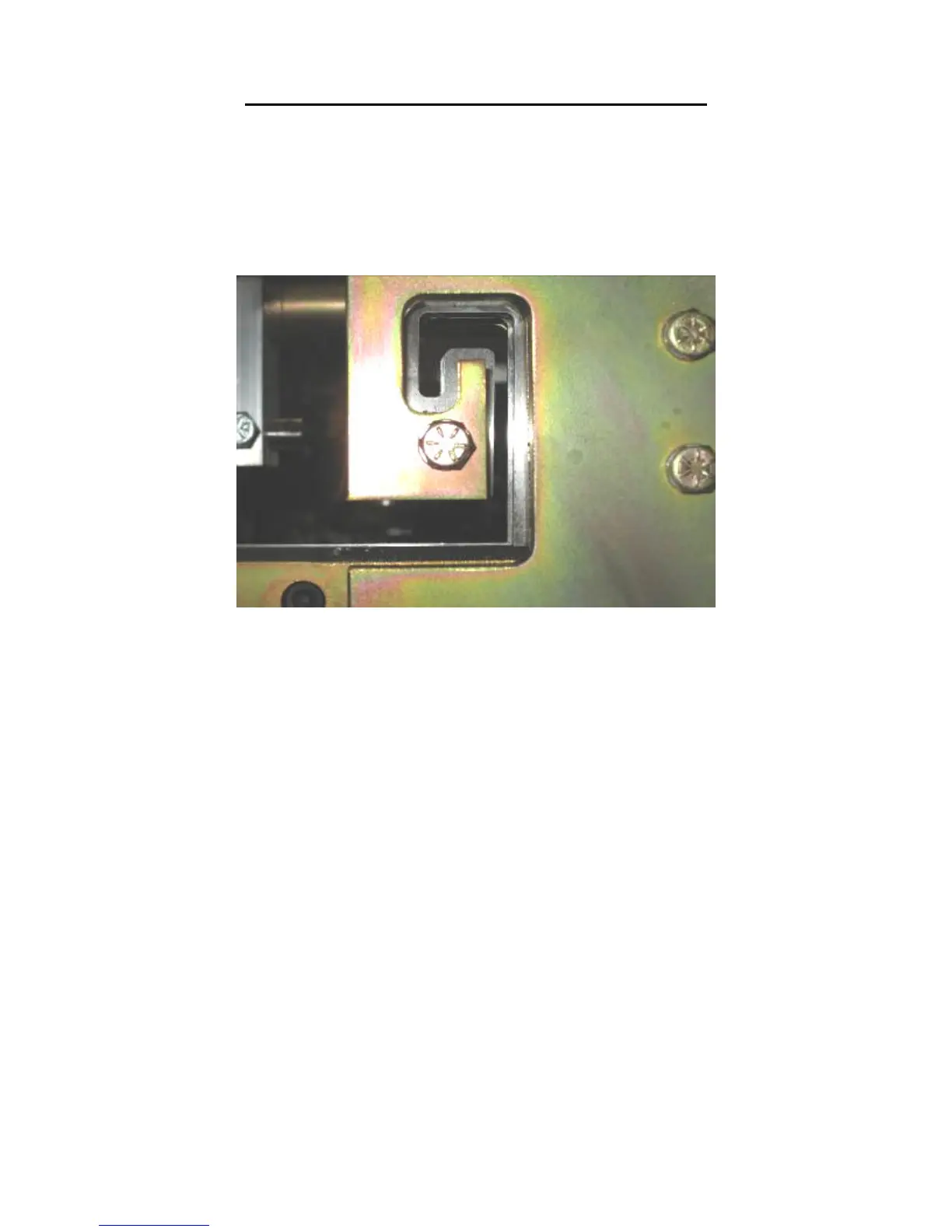

31. Adjust the male and female exit dies so that they are offset to the outside of the

entry die by approximately 1/64” and lock down the two “C” bolts (Figure 58) on

each assembly. This offset is necessary so that after a cut is made, the leading

edge of the panel does not hang up on the exit die.

Figure 58: Exit Die Adjustment

32. Look down the leg of the panel and make sure that the entry and exit dies are not

touching the panel as it passes through them.

33. Start the machine and press the shear down button to cut off the panel, then jog

the material through the shear approximately 2” and stop.

34. Inspect the two cuts and adjust the dies as necessary until an acceptable cut is

achieved. Again, TURN THE MACHINE OFF BEFORE MAKING ANY

ADJUSTMENTS! NEVER REACH THROUGH THE SHEAR WHILE

THE MACHINE IS RUNNING. SERIOUS INJURY COULD RESULT!

35. Once the cut is acceptable, you are ready to start panel production.

Loading...

Loading...