CHAPTER 14

WIDTH CHANGE PROCEDURE

47

22. Visually site through the male entry die and rough align it to the forming tool

“line of fire” by sliding it left or right. Re-install the two “C” bolts into holes

that correspond to the slots. Do not tighten the bolts at this time, just snug

them up.

23. Install the male exit die in the same manner aligning it to the entry die and

again, just snug the bolts.

24. Start the machine and carefully jog the panel up to the shear. Check to see if

the panel will pass through the entry shear die. If not FIRST SHUT THE

MACHINE OFF, then move the entry die so that the panel will pass through

it.

Adjust the entry die so that it is as close to the outside vertical portion of the leg

as possible without touching it. Once this is done, tighten the two “C” bolts on the

entry male shear die assembly.

25. Check the exit shear die to ensure that the material will pass through it. If not

adjust as necessary.

26. Start the machine again and slowly jog the panel approximately 6” past the

exit male shear die assembly and stop. Again, TURN THE MACHINE OFF.

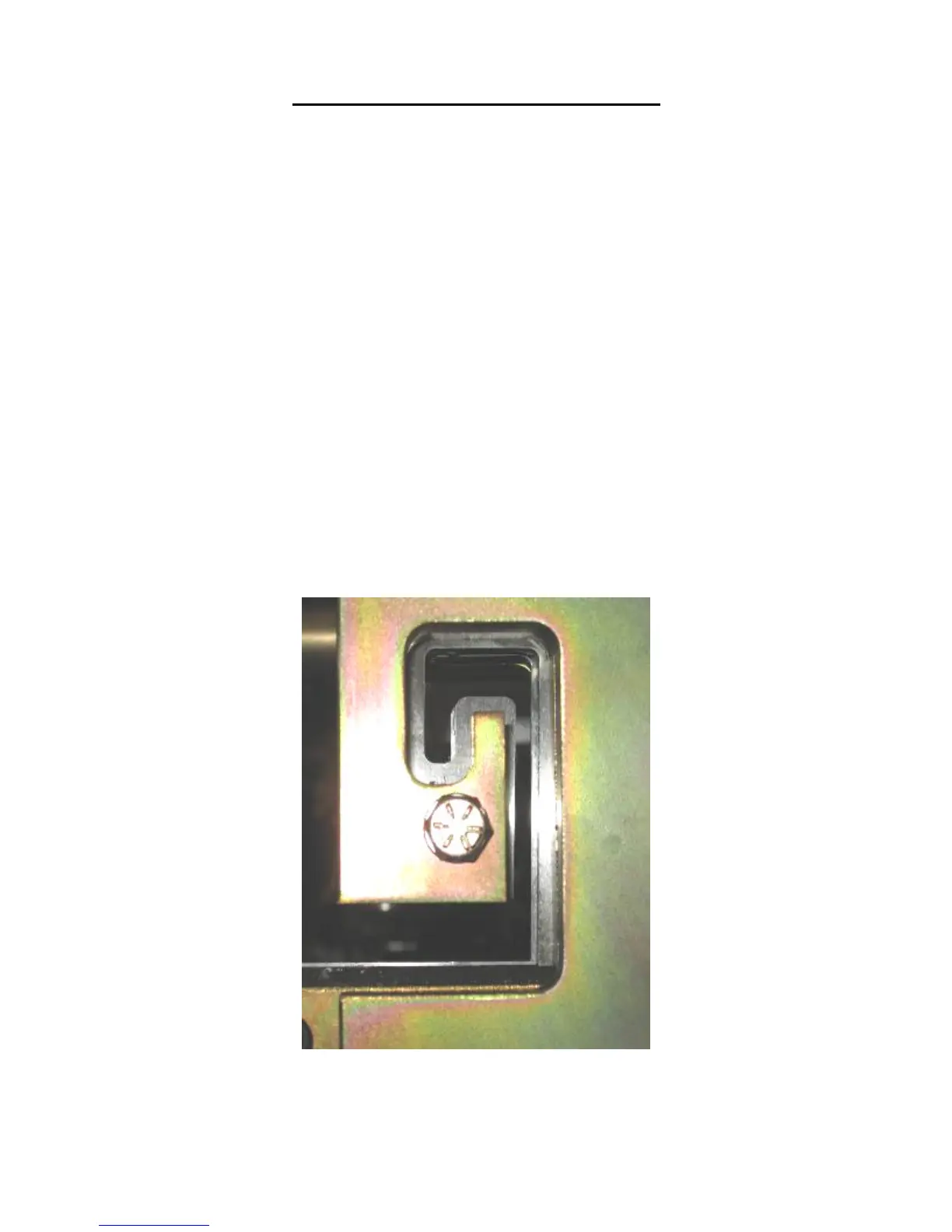

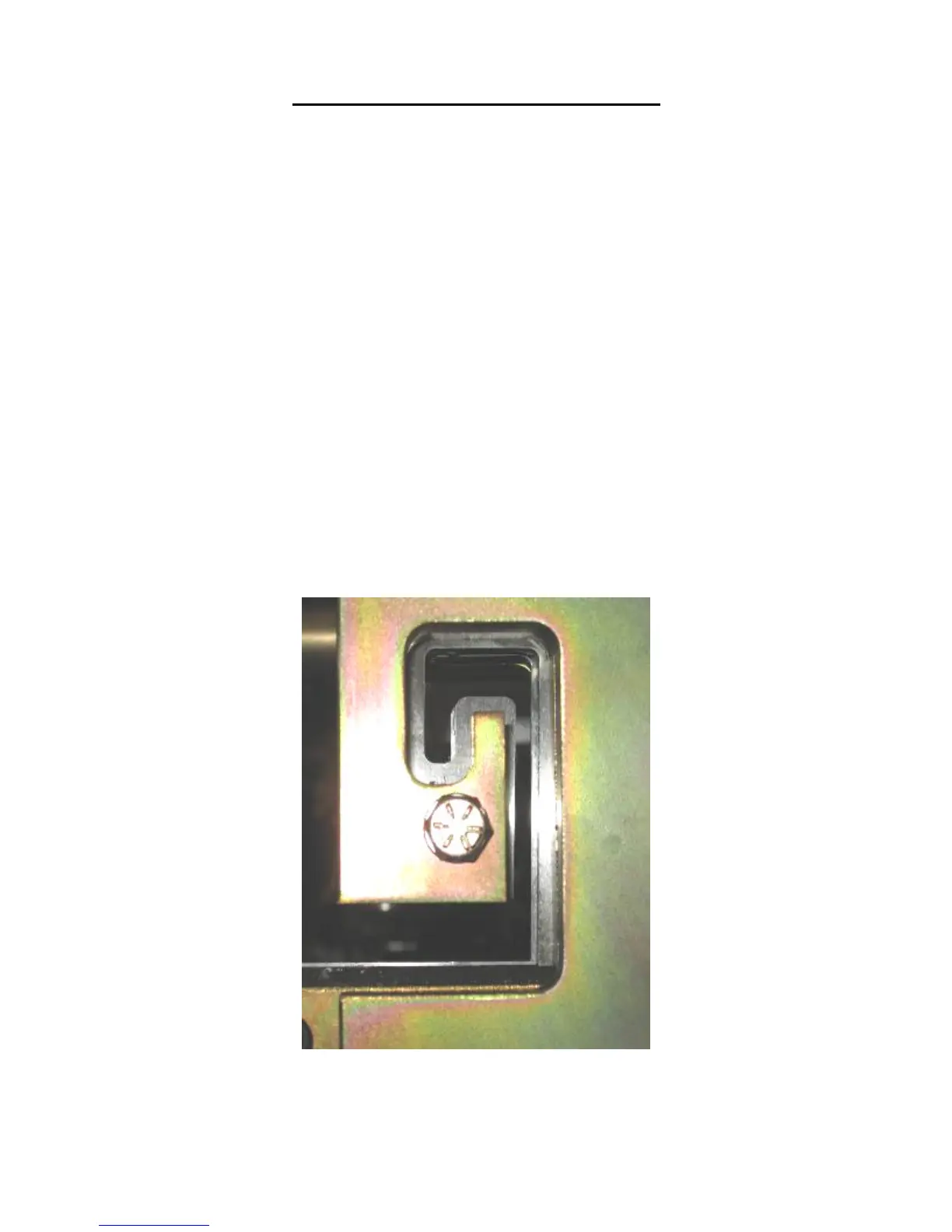

27. Adjust the exit male shear die assembly so that it is offset to the outside of the

entry die by approximately 1/64” and lock down the two “C” bolts (Figure 36)

This offset is necessary so that after a cut is made, the leading edge of the

panel does not hang up on the exit die.

Figure 36: Exit Die Adjustment

28. Look down the leg of the panel and make sure that the entry and exit male

shear die assemblies are not touching the panel as it passes through them.

Loading...

Loading...