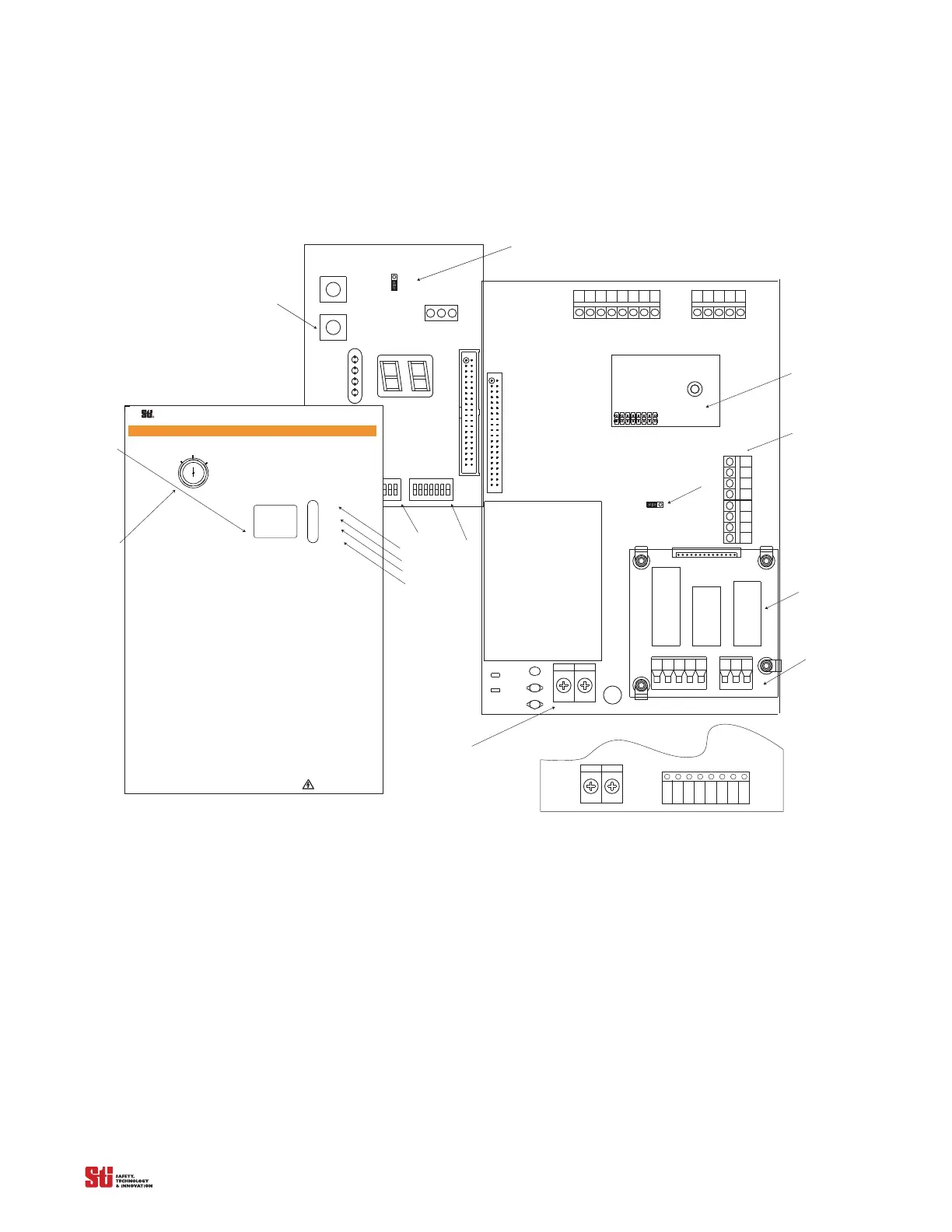

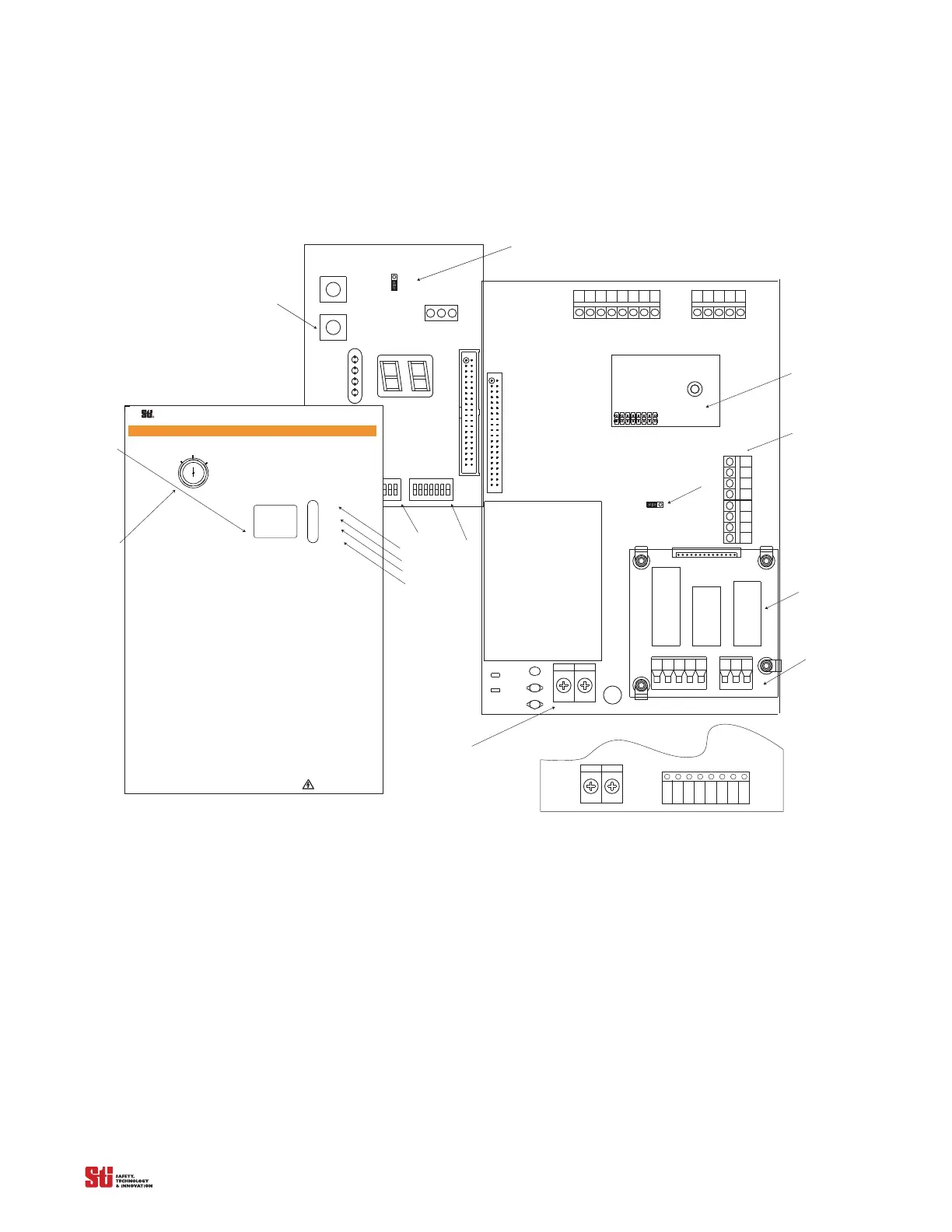

1 2 3451 2 3 456 7 8

2

1

2

1

MPCE MON

ON

OFF

JMP2

BOARD

DEVICENET

OPTIONAL

-Note: Shown with optional Relay Board.

P2

R44

R45

C8

C9

RV1

MCS

TB5

TX

TB6

RX

J1

J3

TB7

AUX

K2

K1

0SSD2 AUX

TB3

TB1

TB2

PS1

0SSD1

F1

N

L

KEYSWITCH

J2

N. O.

N. C.

PROGRAM

START

J1

SWA

SWB

STO P

R UN

RUN

STA R T

INTERLOCK

FB/ CS

W A R N I N G

Scientific Technologies Inc, Fremont, CA 94555 U. S. A.

R

!

T

o test the light curtain, use the appropriate ST I-

supplied test object, or properly sized opaque cylindrical

object.

If you are using the Channel Select or Floating

B lanking features and the object to be ignored does not

completely prevent access to the hazardous area, either

(1) use a mechanical guard or other means to block

access or (2) increase the minimum safe distance and

use a larger test object diameter as explained in the

In

stallation and Operating Manual.

1. Disable the machine. Power on the light curtain.

2. Inspect the machine to ensure entry to the

hazardous area is only through the light curtain sensing

field. If not, additional guarding, including mechanical

barriers may be required.

3. Verify that the mounting distance of the light

curtain is equal to or greater than the minimum safe

distance from the hazardous point. E nsure the operator

is not able to stand un

detected between the light curtain

and the hazard.

4. Check for external damage to the light curtain,

the machine, electrical cables and wiring.

5. Interrupt the sensing field with the

test

object t

o check the effectiveness of the light curtain.

Move the test object inside the perimeter (along the top,

Do Not Remove Or Cover This Label

http://www.sti.com1/ 888/ 510-4357

S TI L abel P/N 28621-0010 re

T

ES T

P

R O CEDUR E

sides and bottom) of the sensing field and up and down

through the center of the sensing field. Verify that the

R ed indicator is ON and the Green indicator is OF F while

the test object is anywhere in the sensing field.

watch for any unprotected access to the point of hazard.

6. Start the machine. Interrupt the sensing field

wi th the test object. T he machine should stop

immediately. Never insert the tes

t object i nto the

dangerous parts of the machine! With the machine at

rest, interrupt the sensing field with the test object.

that the machine will not start with the test object in the

sensing field.

7. E nsure the braking and machine stop systems

are working properly in accordance with the machine

manufacturerÕs requirements. If the machine does not

stop fast enough, adjust the braking system or increase

the distance from the light curtain to the

point hazard.

8. If the safety devices or machine fail any of these

tests, do not run the machine. Immediately lockout the

machine to prevent its use and notify the supervisor

9. If the Channel Select is reprogrammed or

disabled, you must repeat these test procedures.

10. Close and lock the light curtai n contr

enclosure door, if applicable.

Dia g no stic C od es :

00 Normal O peration

01 Normal O peration, waiting for Start signal

02 Normal O pera

tion, Floating Blanking a ctive

03 Normal O peration, Exact Channel Select a ctive

04 Normal O peration, Exact Channel Select a nd

Floating Blanking a ctive

20 G eneral DIP switch fault

21 Invalid switch setting

22 DIP switch settings changed during operation

23 Invalid C hannel Select or MPCE switch settings

30 G eneral Safety O utput fault

40 G eneral MPCE fault

41 MPCE open before safety output (O SSD) activation

43 MPCE open when power is applied

5

0 Internal controller fault

51 Receiver fault

52 Transmitter fault

53 Transmitter and receiver length mismatch or transmitter

and receiver not connected

59 24 V DC power supply fault

Inside Front Lid of the metal chassis controller

19

15

16

14

18

17

20

21

13

9

10

11

12

23

TB4

TB1

Shown with DC Solid State Configuration

Note: For Solid State Configuration, JMP2 and

PS1 are not available.

+

_

22

PR O G RA M

24

2

1

2

1

PROG

START

MPCE

. . . . .

Loading...

Loading...