PIPER AIRCRAFT, INC.

PA-28-161, WARRIOR III

MAINTENANCE MANUAL

PAGE 2

Nov 30/06

3E2

32-20-00

(10) To remove the piston tube plug (21) with O-ring (20) located in the lower end of the tube, the

following procedure may be used:

(a) Remove the nose wheel from the fork as described in 32-40-00.

(b) Loosen and remove the bolt, washer and nut that extends through the piston tube and

block assembly .

(c) Push the plug through the top of the piston tube by use of a rod inserted through the

bottom of the tube.

B. Cleaning, Inspection and Repair

(1) Clean all parts with a suitable dry type cleaning solvent.

(2) Inspect the landing gear oleo assembly component for the following:

(a) Cylinder tube assembly for corrosion, scratches, nicks and excessive wear.

(b) Lock rings for cracks, butts, wear.

(c) Fork assembly for corrosion, scratches, nicks, and misalignment.

(d) Link assembly for elongated holes, cracks, corrosion, scratches, nicks and straightness.

(e) General condition of air valve.

(3) Repair of the oleo is limited to smoothing out minor scratches, nicks and dents and

replacement of parts.

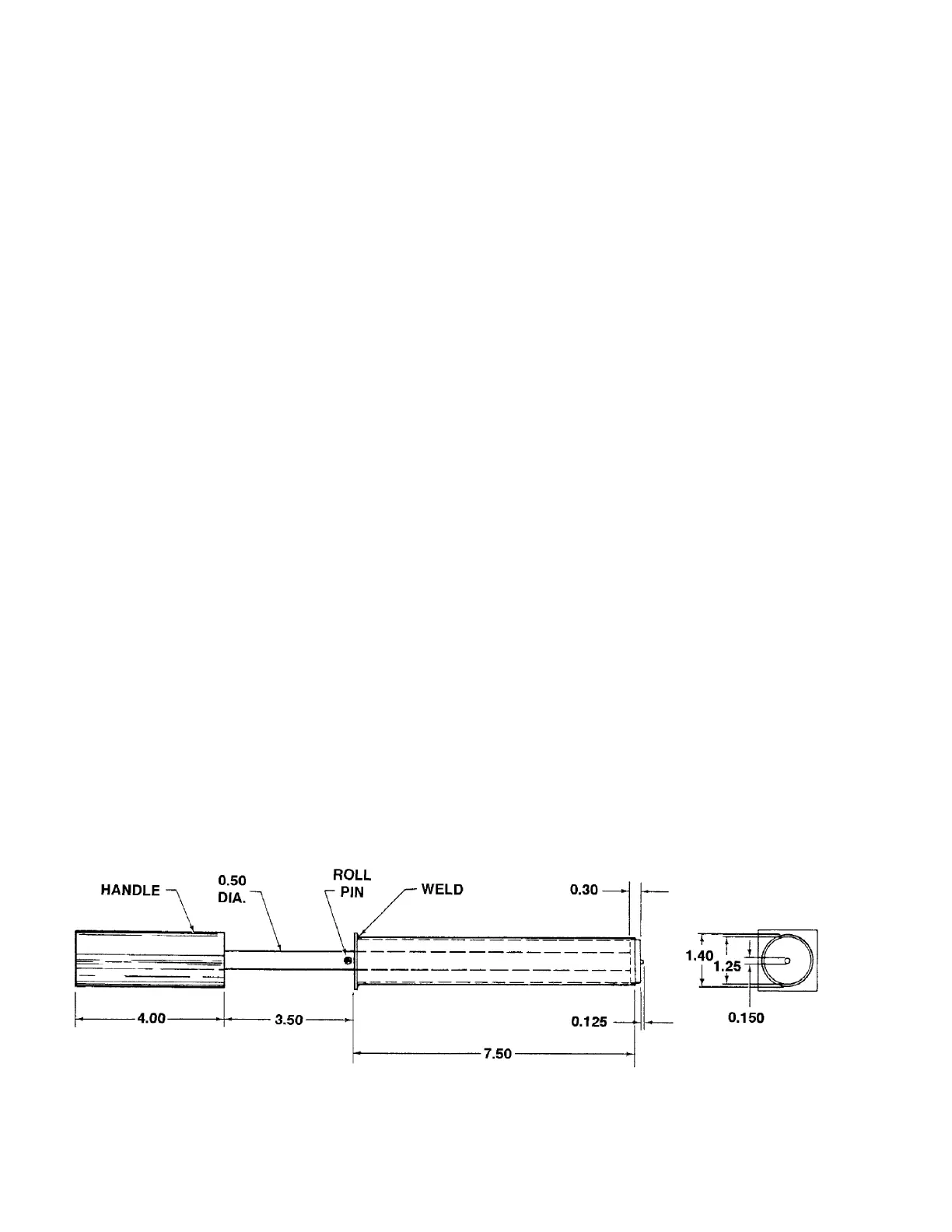

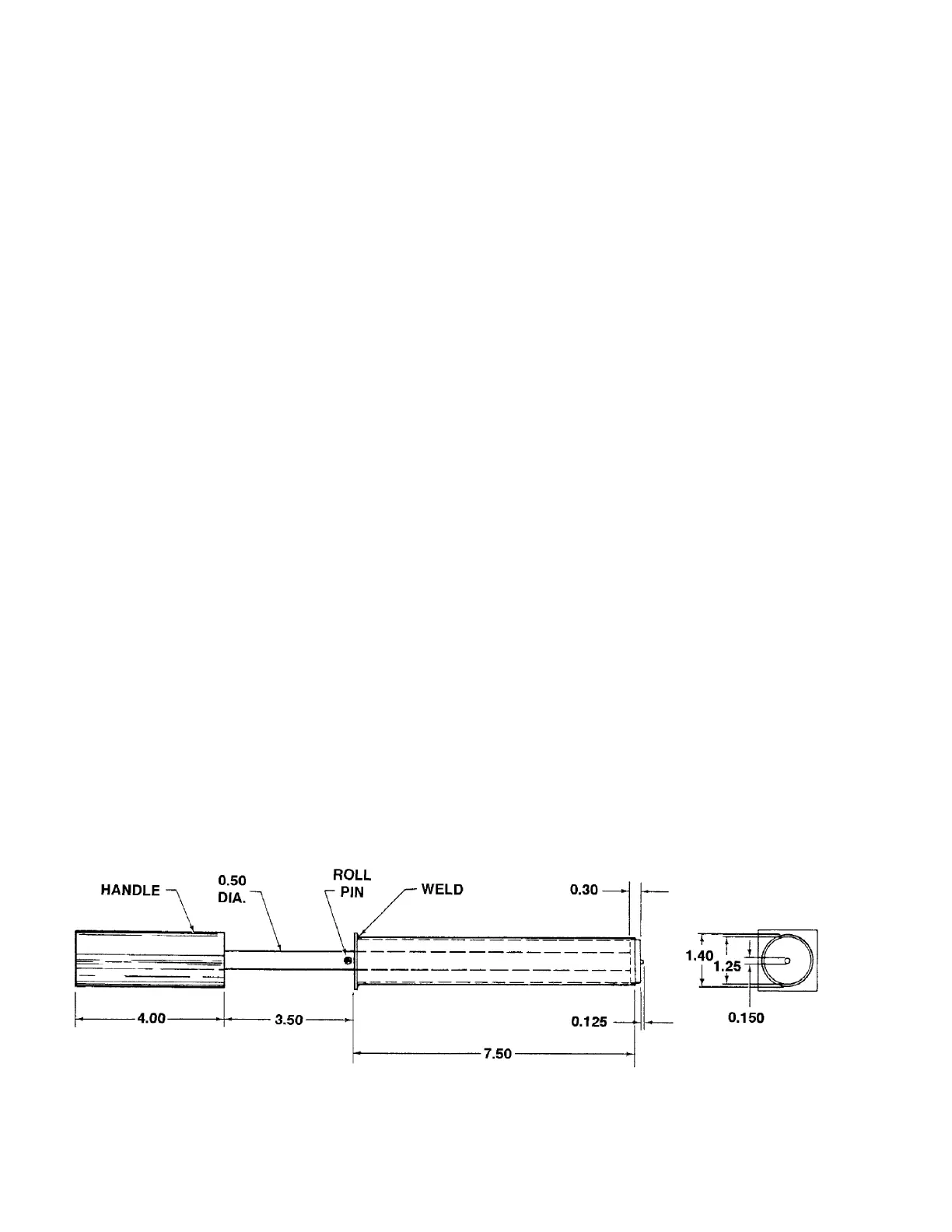

C. Oil Orifice Retainer Ring Installation (Refer to Figures 1 and 2.)

(1) With the piston tube (19) and fork (24) removed from the cylinder(10), ascertain that all traces

of the old retainer ring (12) and removed from the metering tube (11).

(2) A tool can be fabricated to simplify the installation of the new retainer ring. (Refer to Figure 1.)

(3) With the use of the fabricated tool, position the new retainer ring on the end of the tool with the

locating stud.

(4) Insert the tool into the cylinder (10), with the centering stud positioned into the hole in the base

of the metering tube (11).

(5) Hold the tool tightly against the metering tube and slide the sleeve of the tool towards the

metering tube. This will move the new retainer ring (12) over the end of the metering tube and

position itself into the groove of the metering tube (11).

Retainer Ring Installation Tool

Figure 1

Loading...

Loading...