THE ART OF WELDING

P6 HW

16-100 PN-0110008 Rev. 12

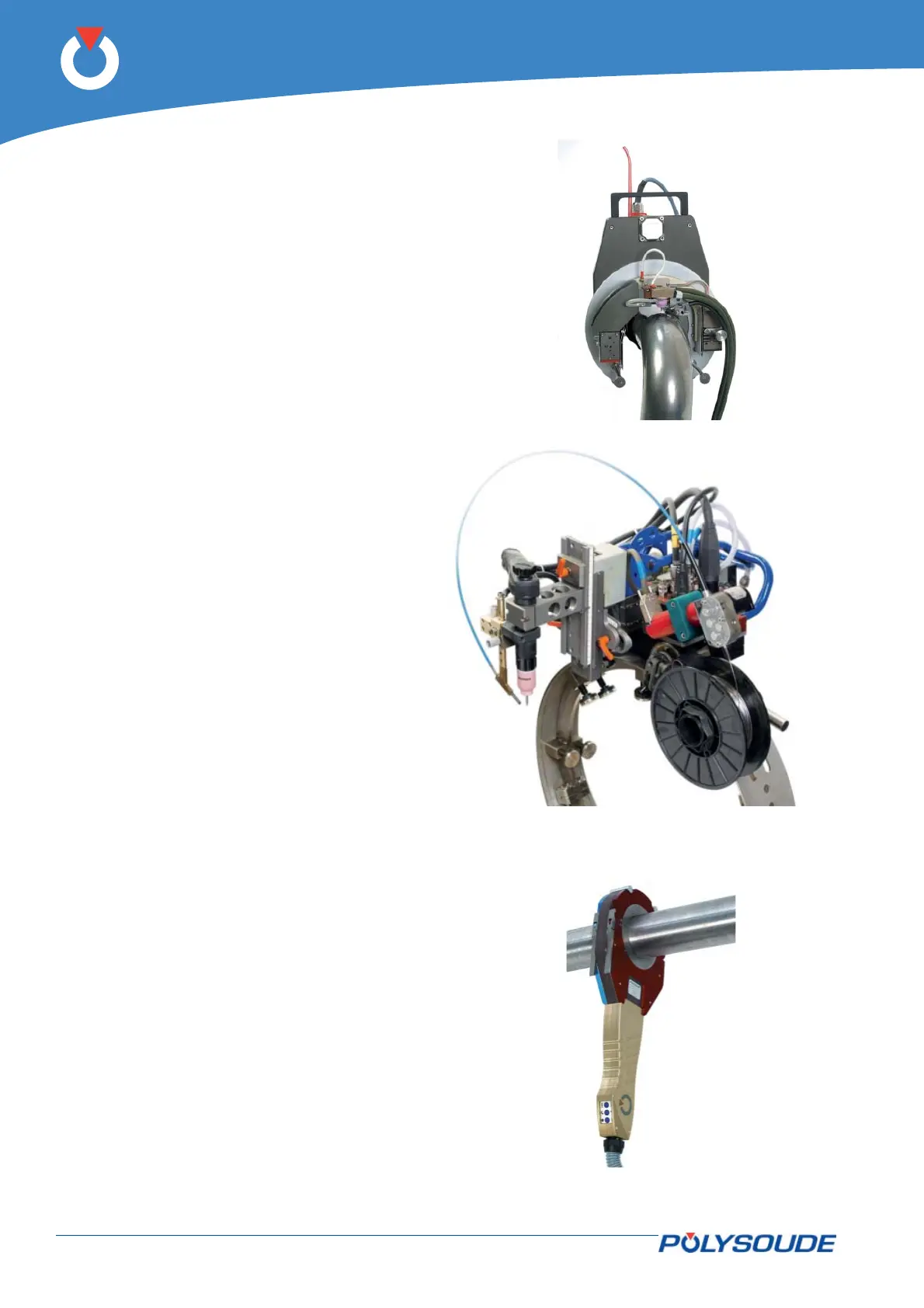

Fig. 3.4 - MU IV welding head

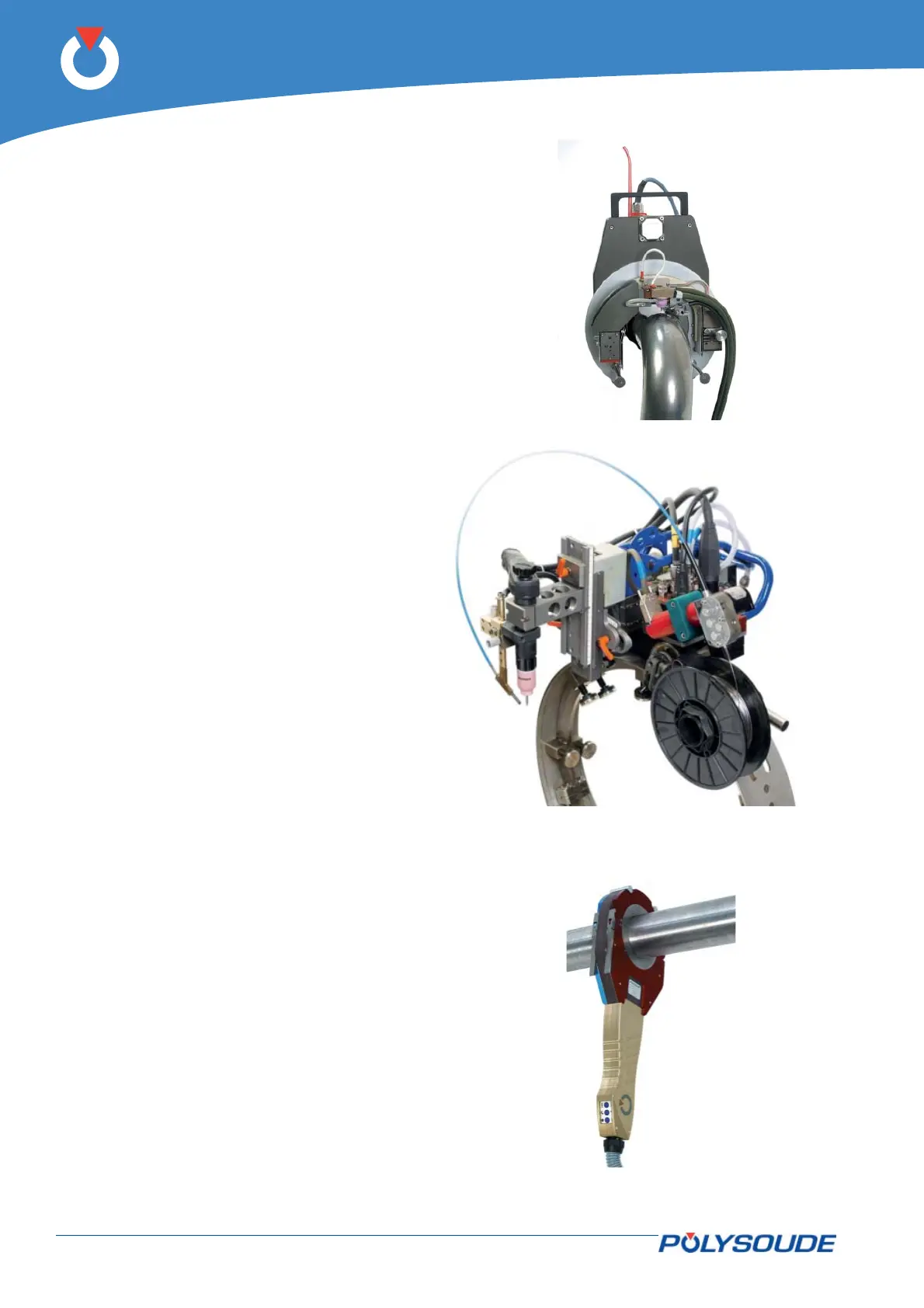

Fig. 3.5 - Polycar welding carriage

Fig. 3.6 - MW welding head

The welding heads3. 2.

These power sources support several of the Polys-

oude series welding heads.

The open welding heads3. 2. 1.

MU IV type (Fig. 3.4) for standard or special •

applications. Modular design. Welding heads

designed for butt welding pipes, with or without

fi ller wire.

Polycar welding head (Fig. 3.5) to weld large •

diameter pipes.

The closed chamber welding heads3. 2. 2.

MW (Fig. 3.6) when high productivity is required. •

High duty cycle due to water cooling. Adaptor

kits available for welding of accessories (elbows,

fl anges, valves, connections, etc.).

Sentry UHP for the demands of ultra high pu-•

rity welding. Welding head with closed chamber

designed for but welding thin pipes without fi ller

wire. It ensures high quality welds and its com-

pact design enables it to be used in areas with

restricted access.

HD when the access to the weld area is restrict-•

ed.

K for applications calling for the best shielding •

gas protection.

Loading...

Loading...