THE ART OF WELDING

P6 HW

10

11

12

11

10

4

2

8

6

7

5

3

1

PN-0110008 Rev. 12 85-100

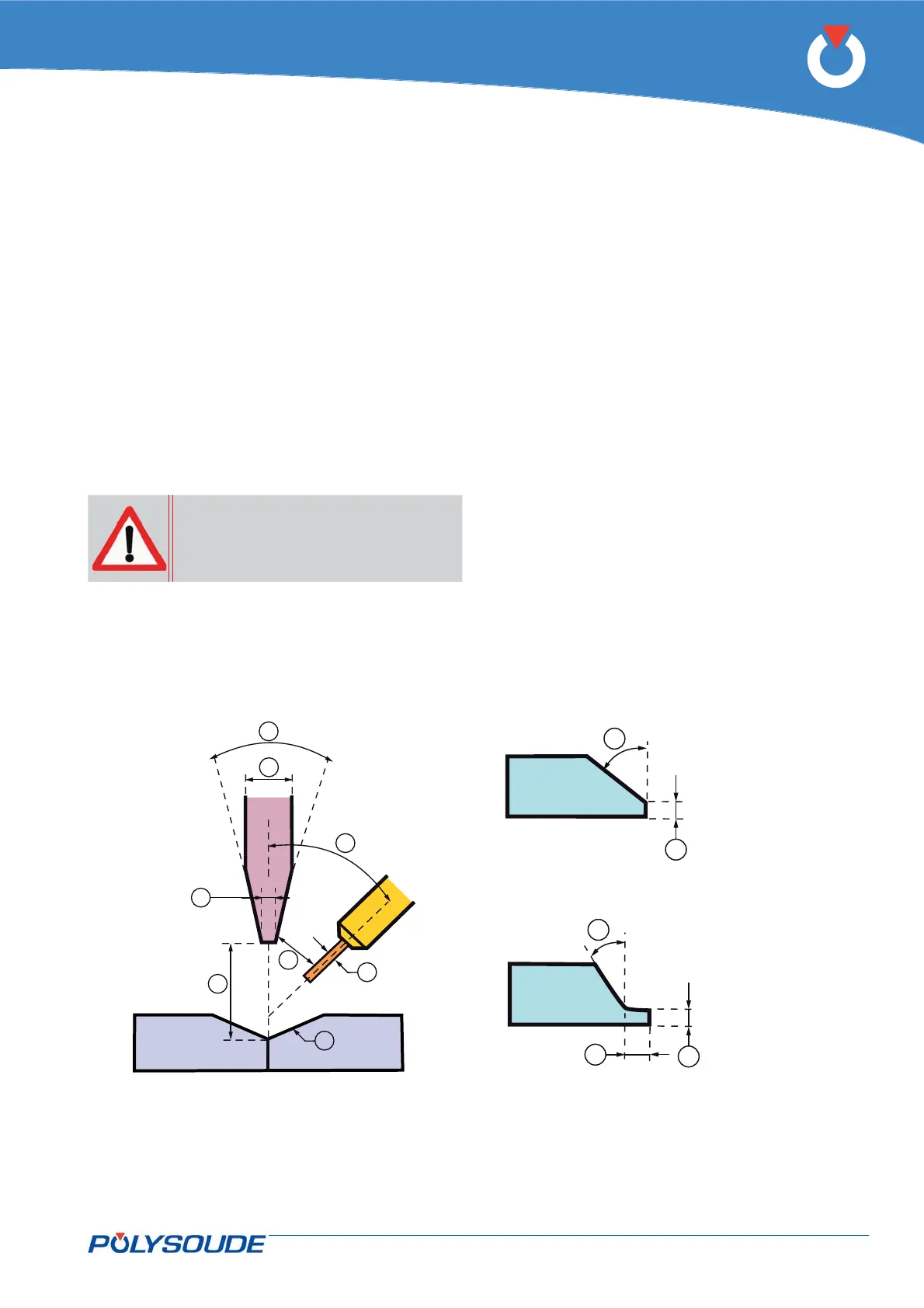

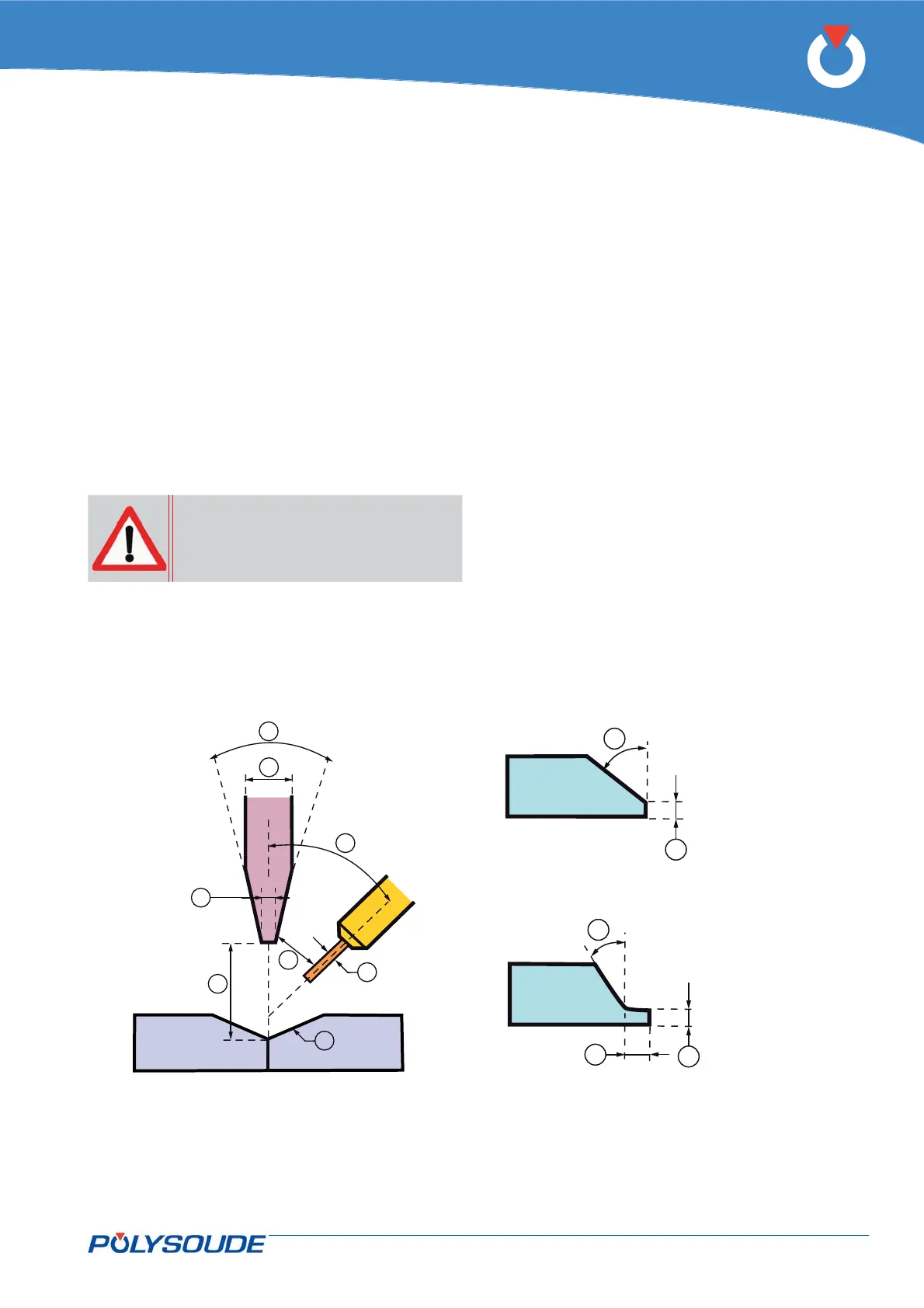

Fig. 7.1 - Non-programmable settings Fig. 7.2 - Preparing tubes

APPENDIX7.

Pre-established WPs7. 1.

The pre-established WPs (Welding Procedures) have

been developed by the Polysoude laboratory to allow

a fast approach to customised procedures. These WPs

correspond to frequently faced applications. Search

criteria are the name of the WP, the tube diameter,

the wall thickness, the base material, the applica-

tion, the type of welding head, the weld position;

the P6 HW power source can offer you the prede-

fi ned WP best suited to the request. You are then

able to modify this user WP to refi ne the welding

procedure.

All WPs are intended to be executed with argon as

shielding gas.

Warning: some applications require

several programs.

All programs that use fi ller wire have been developed

with wire of 0.8 mm diameter.

The result and the quality of a weld is infl uenced

considerably by no-programmable adjustments. In

the predefi ned WPs you will fi nd the values chosen as

each program was generated. The parameters are:

Fig. 7.1 Pos.1 Tube end preparation.

Fig. 7.1 Pos.2 Electrode diameter.

Fig. 7.1 Pos.3 Sharpening angle of the elec-

trode.

Fig. 7.1 Pos.4 Flattened tip of the electrode.

Fig. 7.1 Pos.5 Distance electrode/workpiece.

Fig. 7.1 Pos.6 Filler wire diameter.

Fig. 7.1 Pos.7 Filler wire outlet angle.

Fig. 7.1 Pos.8 Distance electrode/wire.

Fig. 7.1 Pos.9 Start position of the weld.

Fig. 7.2 Pos.10 Preparation angle.

Fig. 7.2 Pos.11 Land thickness.

Fig. 7.2 Pos.12 Land length in case of a J prep.

Single U-butt weld

preparation

Single V-butt weld

preparation

Loading...

Loading...