THE ART OF WELDING

P6 HW

PN-0110008 Rev. 12 71-100

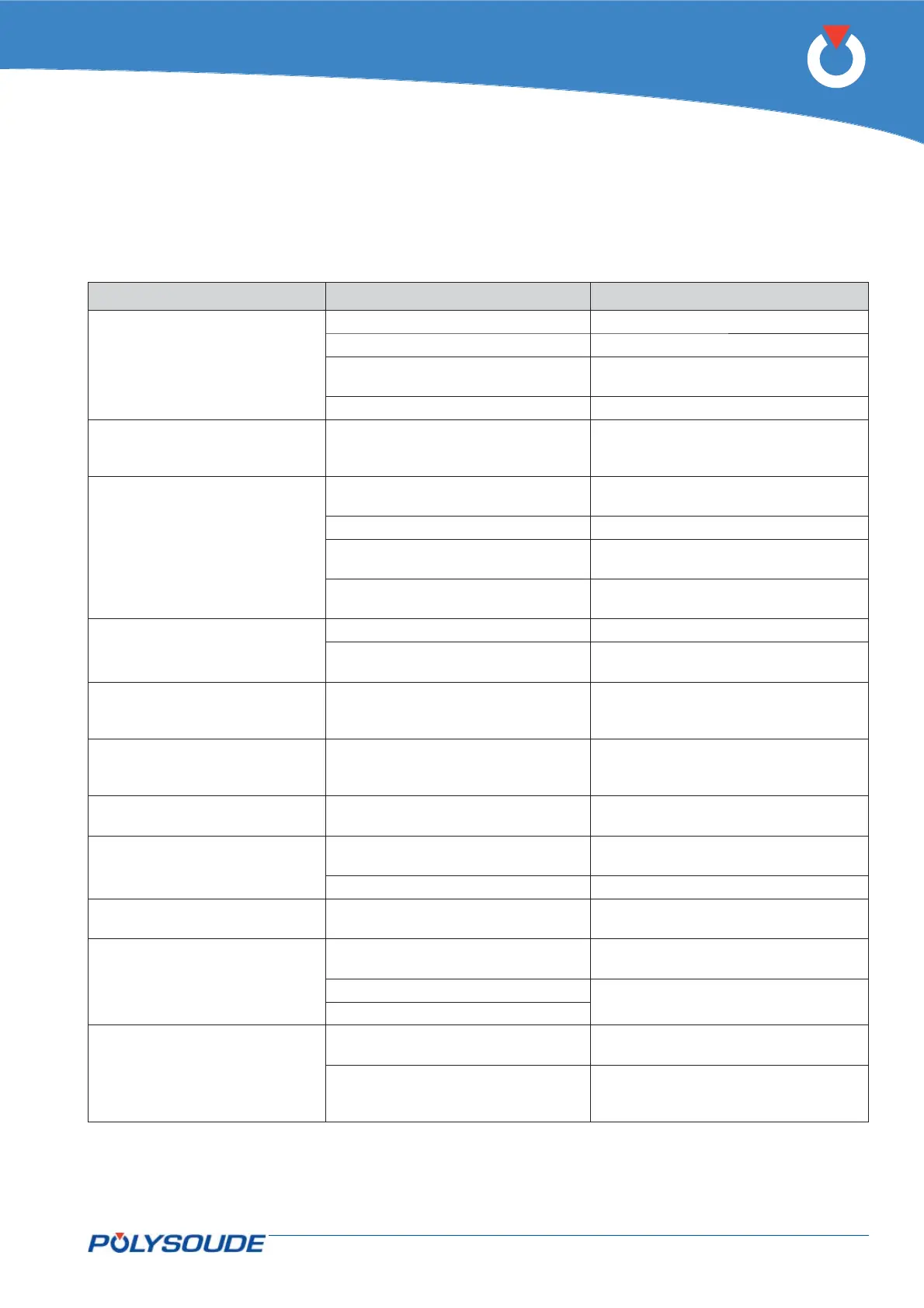

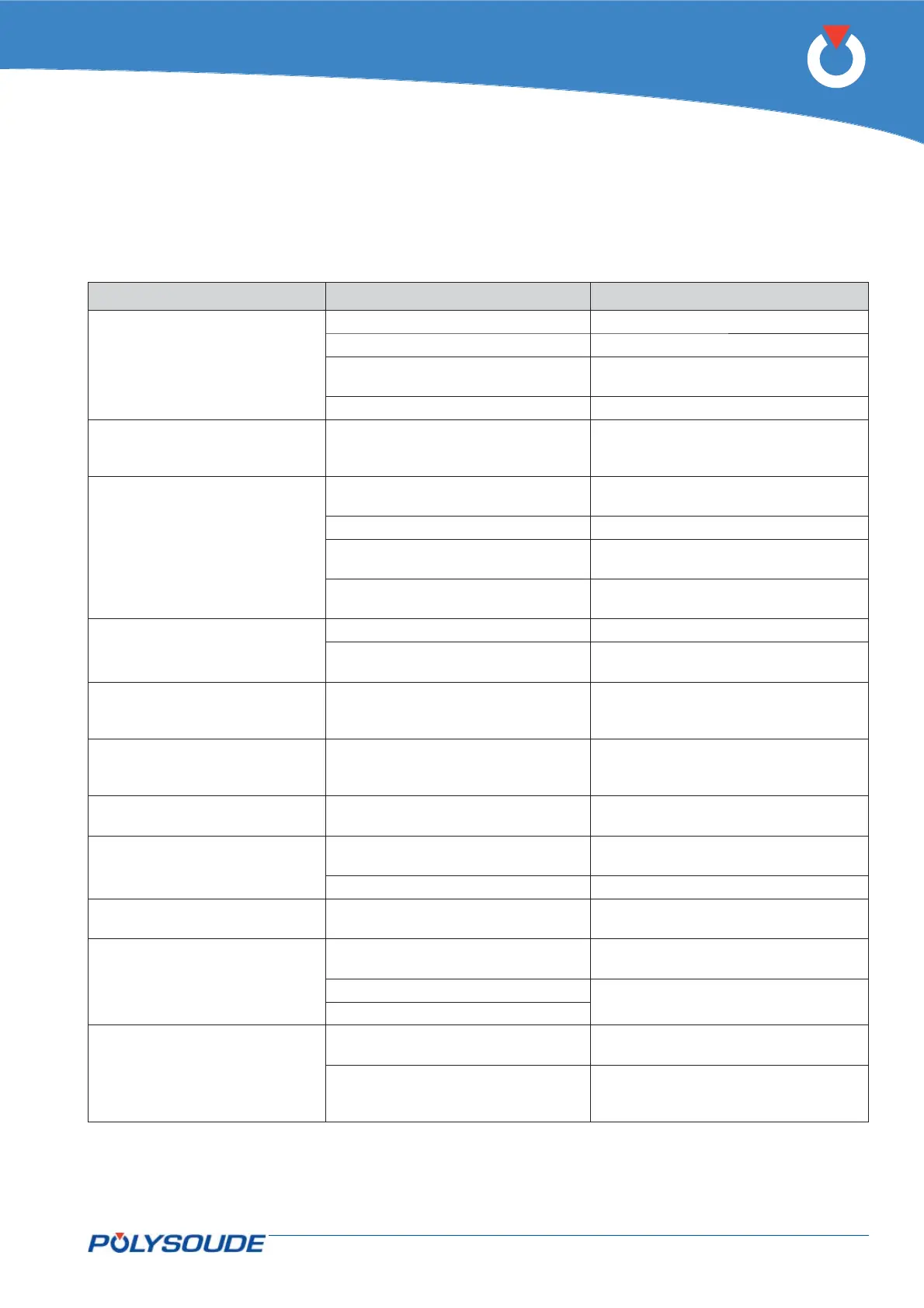

Troubleshooting guide6. 2. 3.

Defects occurring during operation

Problem (Consequence) Possible causes What to do

Impossible to switch the power

source on

Fuse FU1 defect. Replace (chap. 6.2.1).

Plugs or mains supply cables defect. Replace.

Remote control defect (emergency

stop button locked).

Check and correct or replace.

Main switch defect. Check or replace.

Circuit breaker (outside the

power source) releases if the

power source is switched on

Unsuitable circuit breaker.

Install a circuit breaker of 32 A (with D

characteristic) for 400 V mains supply

(see rating plate).

The cycle or a movement (rota-

tion, wire, gas, coolant) starts

on its own

The power source is not connected

to the earth.

Correct.

Remote control defect. Check and correct or replace.

Cable shielding of the remote con-

trol damaged.

Replace the cable.

Remote control card 0028049100

defect.

Replace.

Some buttons of the remote

control pendant are inoperative

Remote control defect. Check and correct or replace.

Remote control card 0028049100

defect.

Replace.

No display on the remote con-

trol or no backlighting

Remote control card 0028049100

or display adapter 0028209200 de-

fect.

Replace.

The parameter value cannot be

modifi ed (buttons "+" and "-"

inoperative)

WP confi guration set to

"modifi cations not allowed".

Change the selection.

Touchscreen is illuminated but

inoperative

Touchscreen controller RS232 defect.

Contact Polysoude After Sales Serv-

ice.

Nothing displayed on the touch-

screen

Connector J17 on the card LVDS

0028069100 is unplugged.

Check.

Card LVDS 0028069100 defect. Replace.

No cycle start possible with a

manual torch

Bad connection of the manual torch

plug or wrong cabling.

Check and correct.

Gas fl ow rate too low

(Immediate stop)

Gas channel inside the welding head

blocked.

Check, clean.

Gas safety device defect.

Must be checked and, if necessary, re-

placed by a qualifi ed electrician.

Gas solenoid valve defect.

No rotation (head or wire feed

unit) without error message

Shear pin of the welding head or

wire feed unit broken.

Replace (consult operating manual of

the head or the wire feed unit).

Power source converter cards

0028019100 (rotation and/or wire

feeding) defect.

Replace.

Loading...

Loading...