THE ART OF WELDING

P6 HW

72-100 PN-0110008 Rev. 12

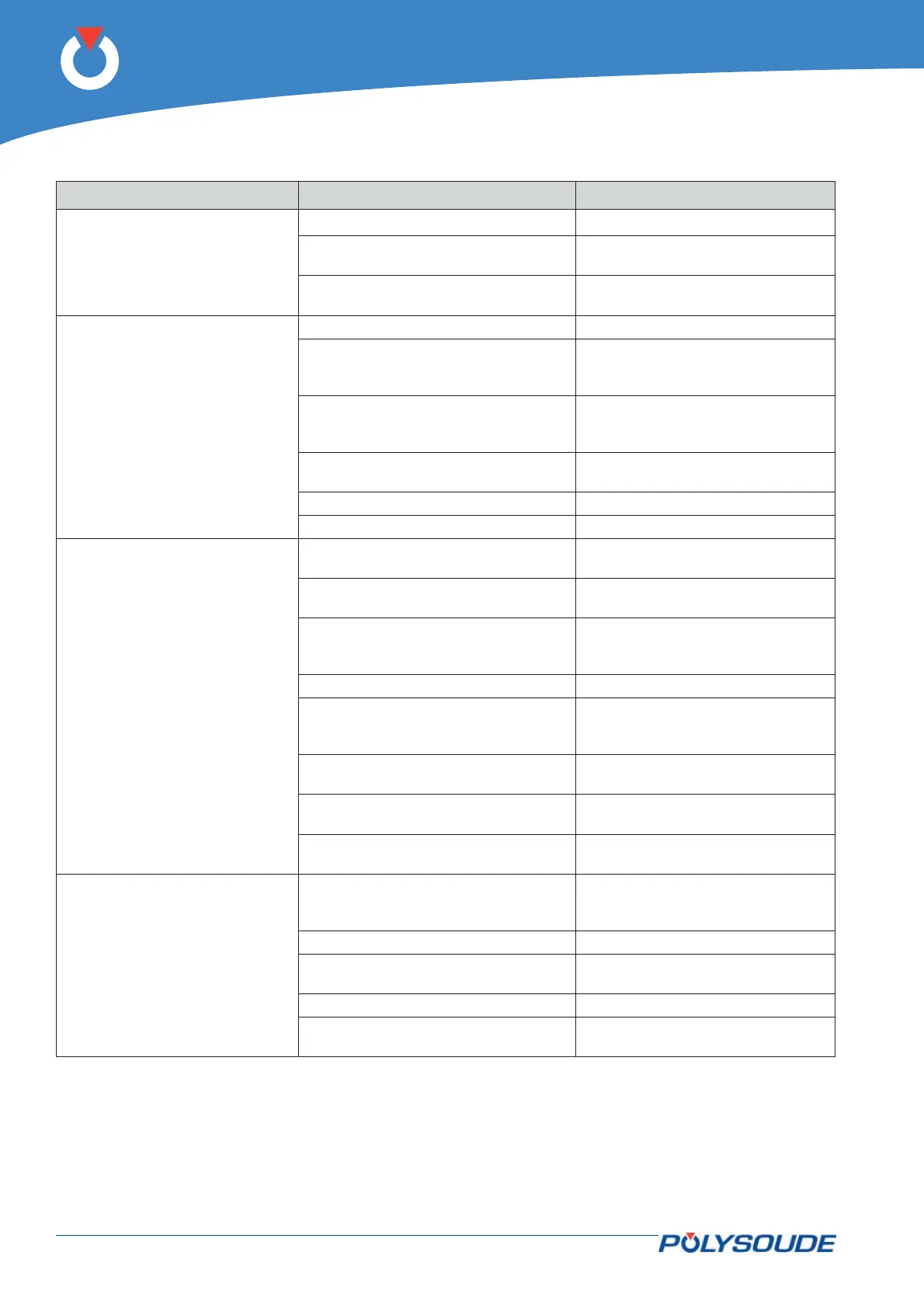

Problem (Consequence) Possible causes What to do

Gas

(Immediate stop)

Gas bottle empty or valve closed. Check, replace or open.

Quick coupling of the welding head

badly connected.

Check.

Solenoid valve defect.

Must be checked and, if necessary,

replaced by a qualifi ed electrician.

Cooling unit

(Imposed downslope)

Coolant level too low. Check and correct.

Coolant circuit fouled.

Check, empty and clean the circuit,

clean the water fi lter. Fill up with

fresh coolant.

Shunt of the cooling circuit not connect-

ed (air cooled closed chamber welding

heads).

Check and correct (§ 4.3.3).

Quick couplings of the welding head

badly connected.

Check and correct.

Fuse defect. Check and change (§ 6.2.1).

Polygaine defect (MU welding heads). Replace.

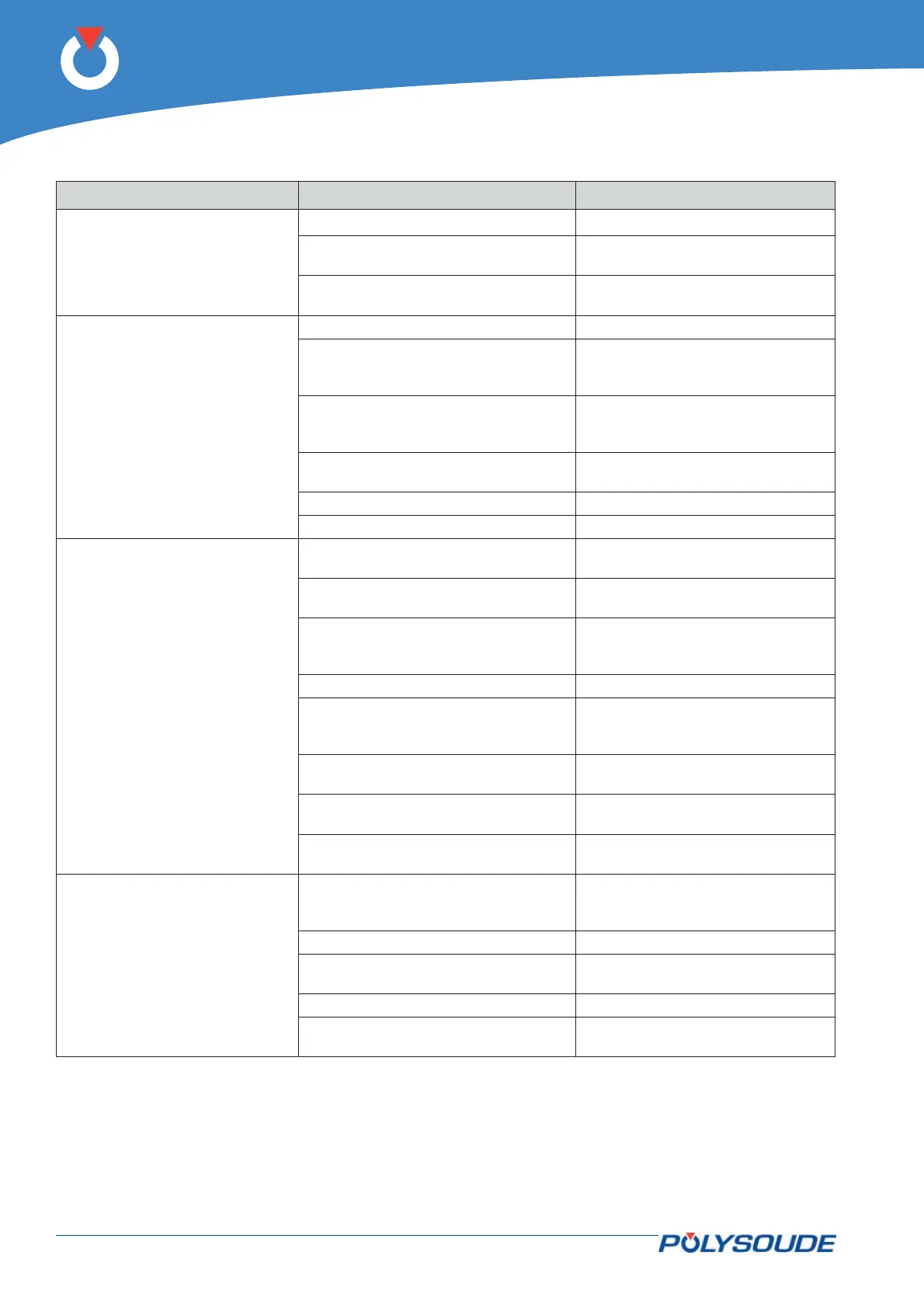

Ignition

(Immediate stop)

Weld current cable badly connected

or cut.

Correct or replace.

Earth connection not clamped at a

clean zone.

Move earth connection (§ 4.3.2 or

4.3.6).

Electrode contaminated or too far

from workpiece.

Consult operation manual of the

welding head for electrode chang-

ing.

Polygaine defect (MU welding heads). Replace.

Ignition device not fi tted or badly po-

sitioned (welding heads MU, TP, TS

…).

Change position.

Gas not suitable, gas fl ow rate not

adapted.

Try with argon.

Power source badly adjusted.

Contact Polysoude After Sales

Service.

Current source defect.

Contact Polysoude After Sales

Service.

Arc loss

(Immediate stop)

Electrode tip damaged or wrongly

prepared.

Consult operation manual of the

welding head for electrode chang-

ing.

Wrong distance electrode/workpiece. Correct.

Poor gas protection.

Check fl ow rate, gas diffuser, clean,

correct.

Weld current programmed too low. Correct.

Ignition device too close to the torch

(heads MU, TP, TS …).

Correct the position.

Loading...

Loading...