Section 00: GENERAL INFORMATION

3

PA1593

STEEL – STEEL WELDING

CAUTION

Before welding, perform multiplex modules disconnection procedure.

NOTE

Welding surfaces must be free of scale, slag, rust, paint, grease, humidity or other foreign material that

would render welding impossible.

DANGER

Only a qualified and experienced person must do welding.

o FCAW (Flux Cored Arc Welding) process ;

o Electrode wire conforms to A5.20 AWS (American Welding Society) specifications ;

o E4801T-9-CH, type electrode wire with 0,045“ diameter (1,14 mm) ;

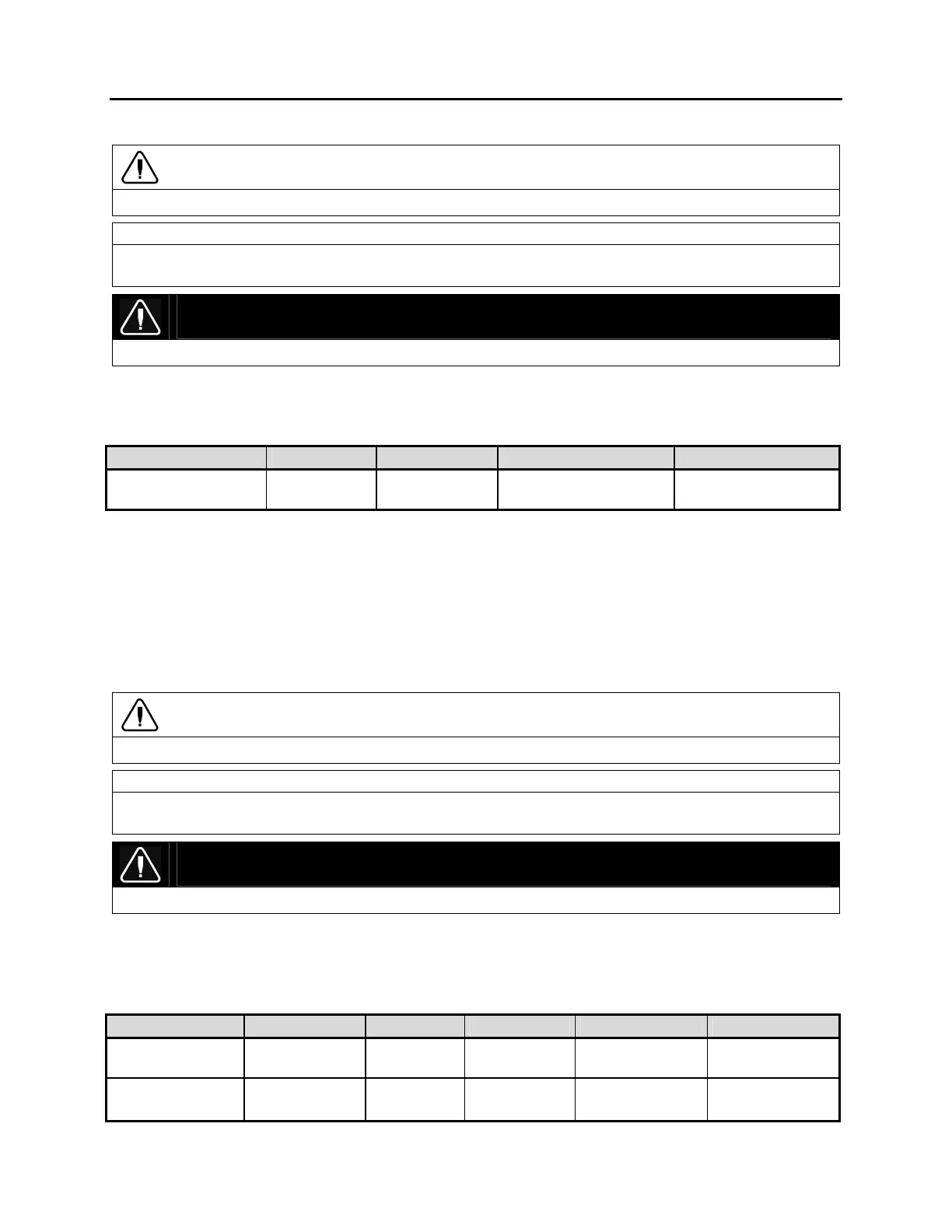

Material Thickness

olta

e Current Wire Feed Rate Shieldin

Gas

1/8” to ½” 26 ± 2 volts 260 Amps 450 ipm. approx.

75% argon – 25%

CO2 or 100% CO2

If necessary and with great care to prevent perforating the material, it is possible to use a conventional

electric arc welding machine according to the following specifications:

o SMAW (Shielded Metal-Arc Welding) process ;

o Welding rod conforms to A5.1 of AWS (American Welding Society) specifications; E 7018 type

welding rod with 1/8” diameter (3,2 mm).

o Current: 100 amperes to 150 amperes; optimum at 120 amps.

It is important to grind weld bead starts and stops and also to grind arc strikes from surfaces.

STEEL - STAINLESS STEEL OR STAINLESS STEEL - STAINLESS STEEL WELDING

CAUTION

Before welding, perform multiplex modules disconnection procedure.

NOTE

Welding surfaces must be free of scale, slag, rust, paint, grease, humidity or other foreign material that

would render welding impossible.

DANGER

Only a qualified and experienced person must do welding.

o GMAW (Gas Metal-Arc Welding) process;

o Welding wire conforms to AWS (American Welding Standards) A5.9 specifications;

o 308LSi type welding wire with 0.035" diameter (0,9 mm);

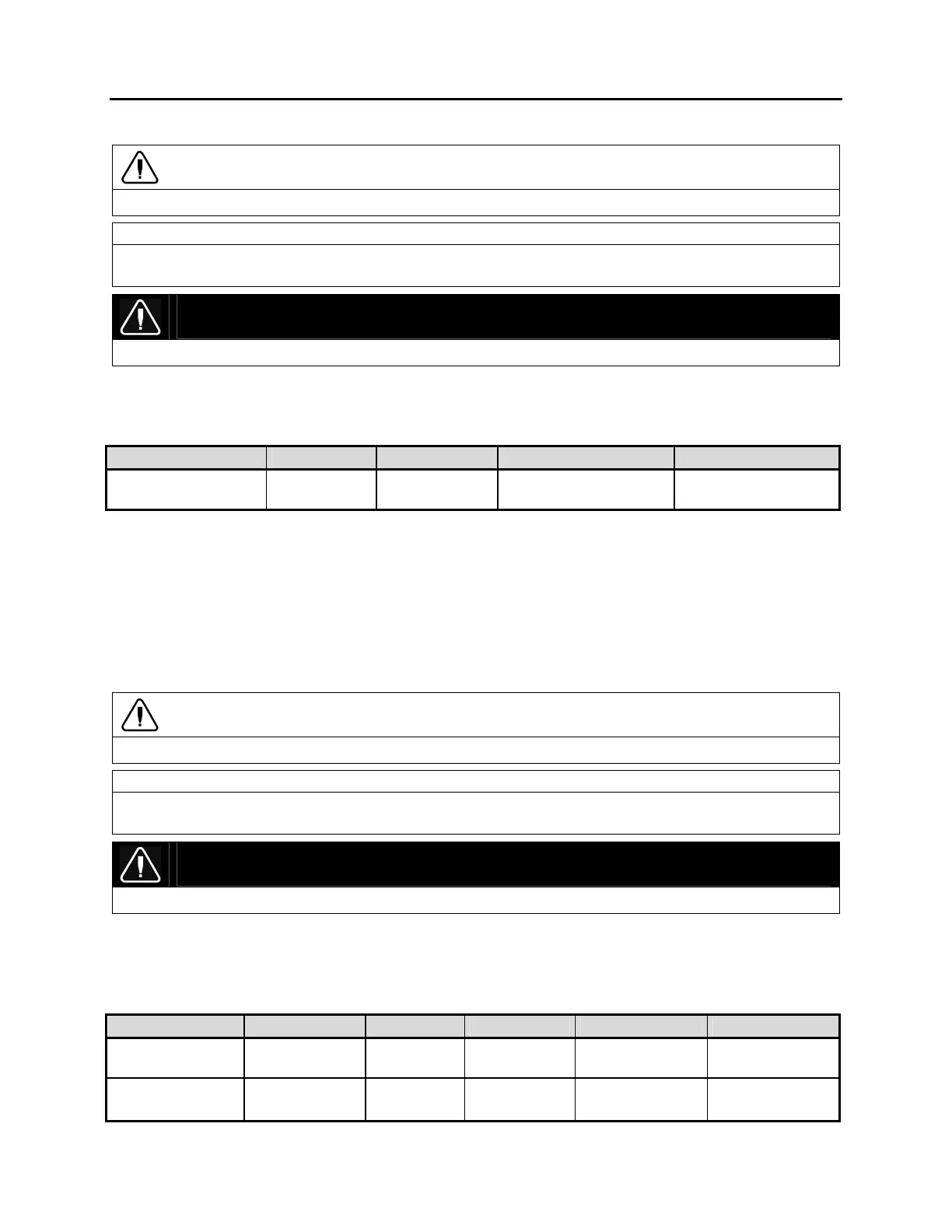

STEEL - STAINLESS STEEL WELDING

Steel Thickness SS Thickness

olta

e Current Wire Feed Rate Shieldin

Gas

Less than 1/8” Any type 20±1.5 volts 130±15 Amps 290 ipm approx.

90% He, 7.5%

Ar, 2.5% CO2

1/8” and more Any type 22±1.5 volts 160±15 Amps 330 ipm approx.

90% He, 7.5%

Ar, 2.5% CO2

Loading...

Loading...