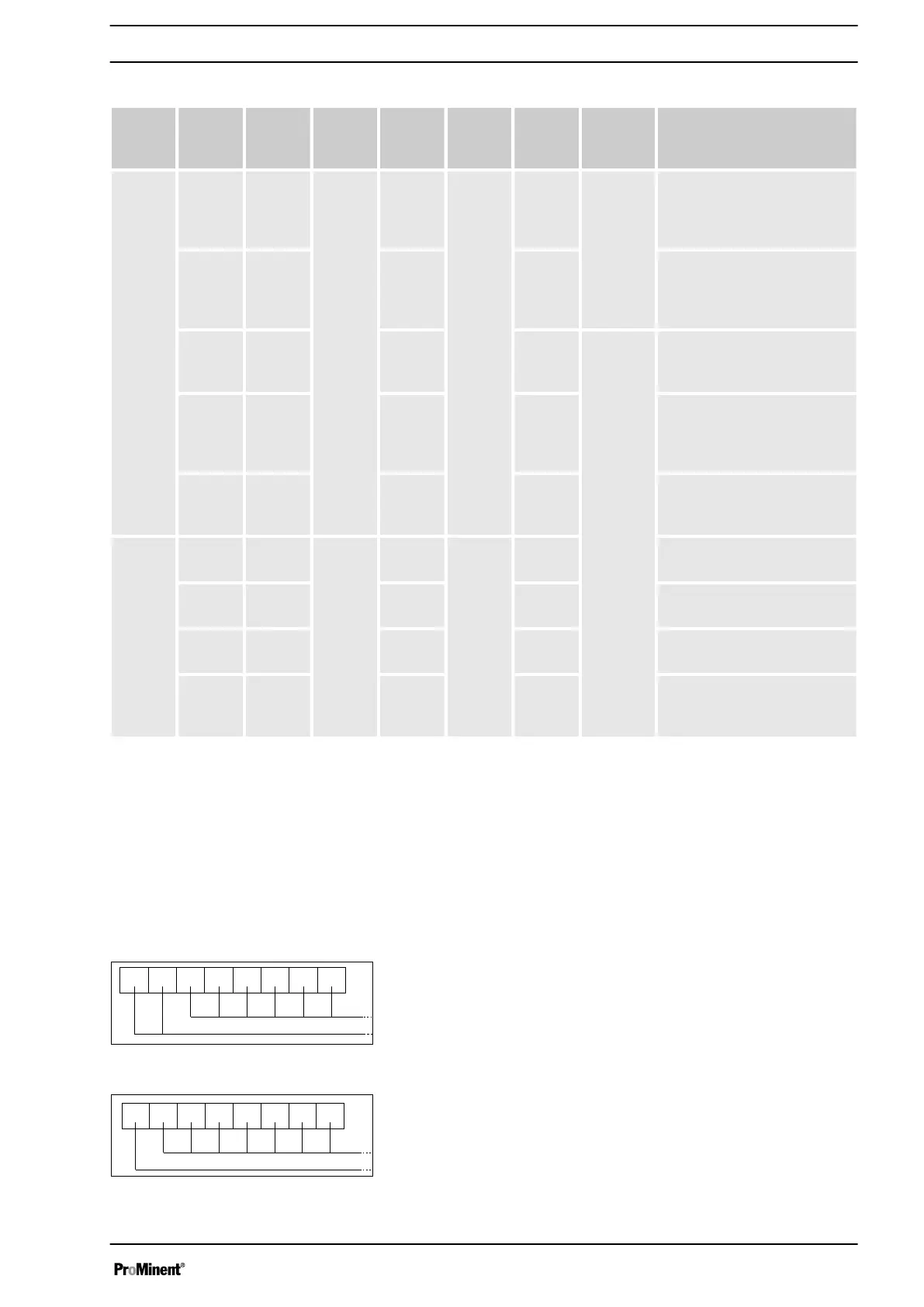

Tab. 37: Strokes / quantity and individual data

Module/

slot

Index Name Module

name

Diag.

number

Identifi‐

cation

(hex)

Type Dataflow

*

Description

11 1 Reset

stroke

counter

Strokes

/quan‐

tity

20 C0,81,

C5

u8 S If the value changes from 1

to 0, the

‘Stroke counter’

(total number of strokes) is

reset

2 Reset

quantity

counter

21 u8 If the value changes from 1

to 0, the

‘Volume counter’

(total number of litres) is

reset

3 Stroke

counter

22 u32 R Count the number of

strokes - since the last

reset (

‘Stroke counter’

)

4 Quan‐

tity

counter

23 f32 Count the metering vol‐

umes in litres - since the

last reset (

‘Volume

counter’

)

5 Litres

per

stroke

24 f32 Litres per stroke

acycl‐

ical

only /

12

1 Identity

code

25 s32 Pump identity code

2 Serial

number

26 s16 Pump serial number

3 Name 27 s32 Pump name (freely edit‐

able)

4 Installa‐

tion

location

28 s32 Installation site (freely edit‐

able)

* R = read, W = write

In conformity with PROFIBUS

®

standard, the device makes the

[Get_Sl_Diag]

service available. The diagnostics data comprise

standard diagnostics information (6-Bytes according to PRO‐

FIBUS

®

standard) and any possible diagnostics data specific to the

device. A maximum of 63 bytes can be inserted for the device-spe‐

cific diagnostics data. The first 4 bytes in the PROFIBUS

®

standard

are specified from this:

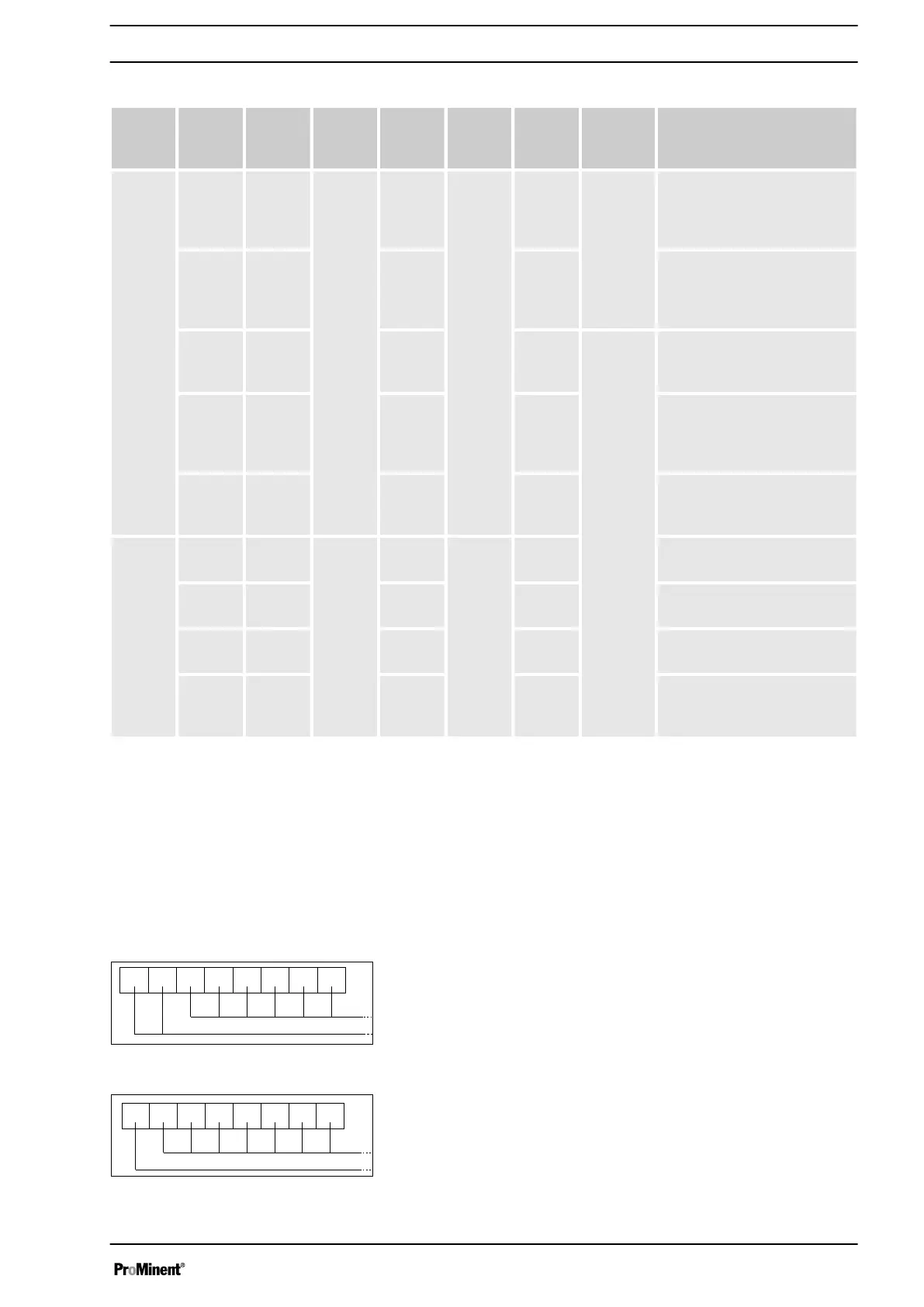

Encode the byte sign_len as follows:

Length of the DU status including the header byte: 04..63

Flags ‘device-related diagnostics’: 00 constant

Encode the byte status_type as follows:

Status type: 48 (manufacturer specific)

Flags ‘Status’: 1 constant

Diagnostics frame

Supplementary Operating Instructions PROFIBUS

®

77

Loading...

Loading...