- 67 - V08 en, SCC

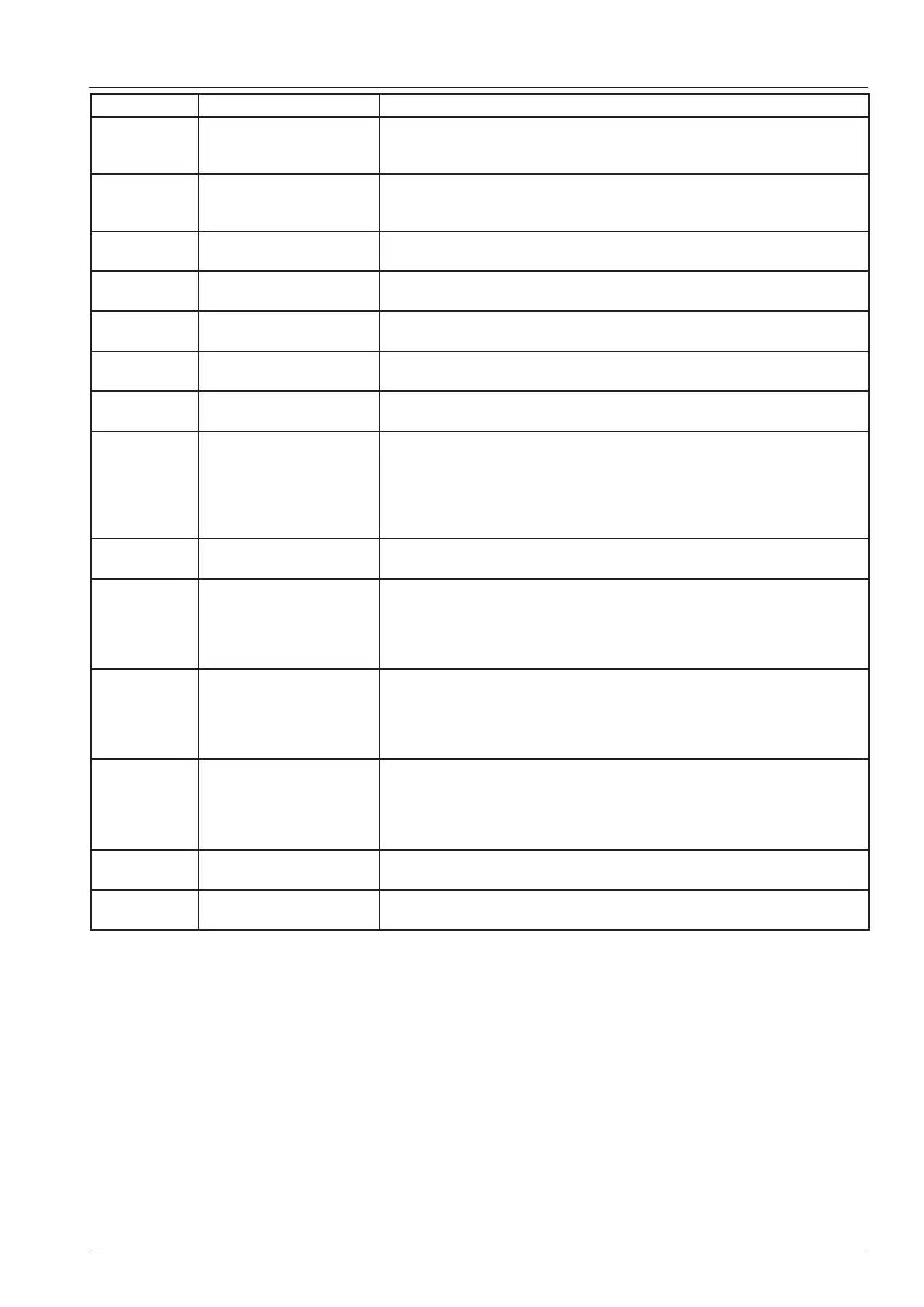

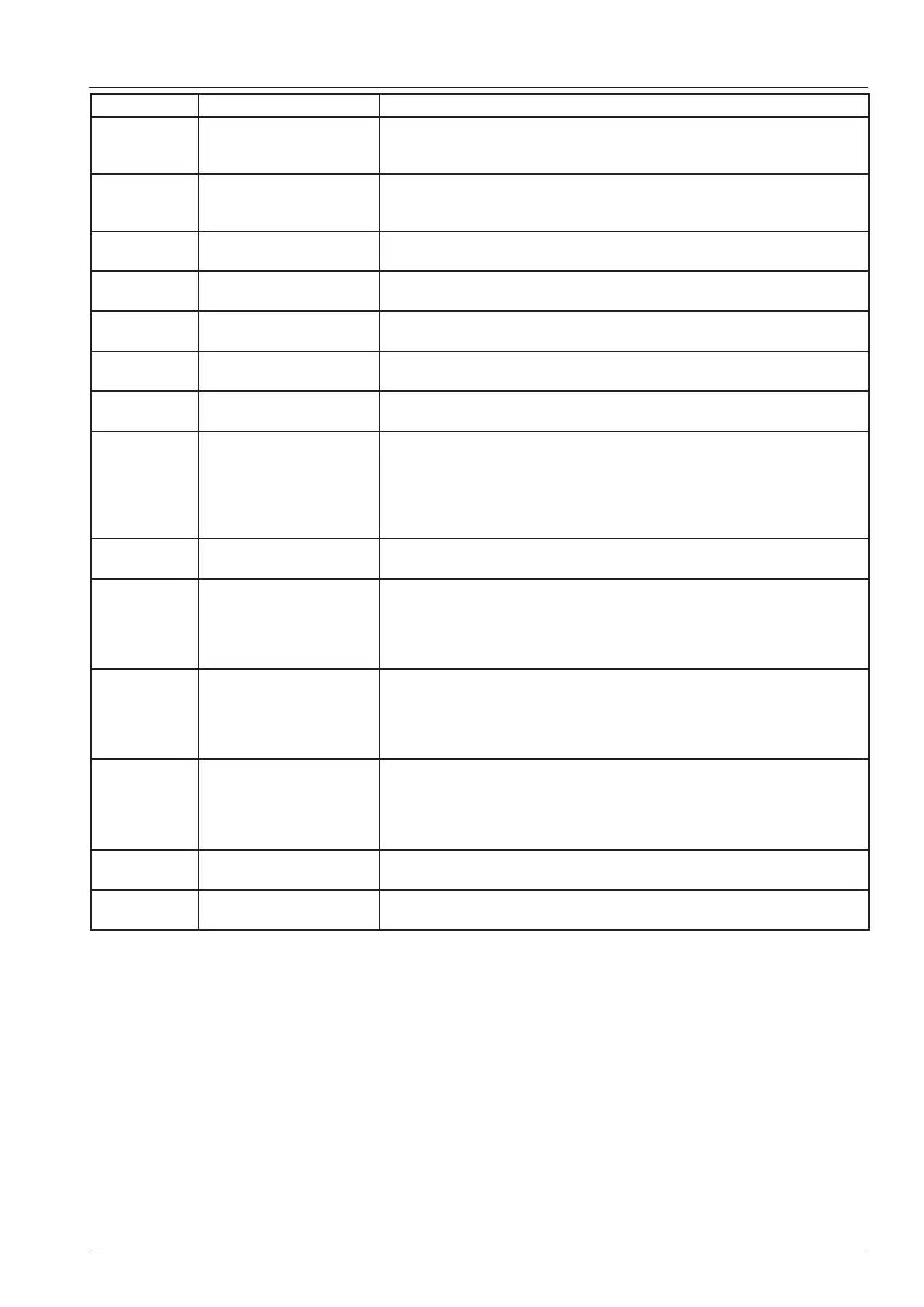

Error message Service

Display Denition Reason - Remedy

Service 10 water is not pumped o

during SC-Automatic

SC pump defective or blocked

Drain hose of SC pump blocked

Check SC pump and hose

Service 11 CDS sensor sends too many

pulses during relling steam

generator

CDS sensor not set to 1000 pulses / liter

Air brake valve above steam generator not closing during lling

Check level electrode and water path to steam generator for leakage

Service 12 CDS sensor

without signal

CDS sensor defective, but level electrode senses water

Check water pressure, replace CDS sensor

Service 13 Steam generator is not

relled during steam mode

Steam generator is not relled during steam mode => foced lling

check 0-1 signal of level electrode to PCB

Service 14 Level electrode doesn`t

recognise water;

CDS sensor measured enough pulses but level electrode does not sense water

Check water conductivity possibly too low, osmosis water treatment

Service 17 Conict with external me-

mory SD card

essential unit data are missing (energy, size, etc)

Run recovery soware

Service 19.1 Conict with external me-

mory SD card

Data can not be written successfully onto SD card

Change SD card

Service 20 -x- Thermocouple

defective

thermocouple defective.

20.1=cabinet B1

20.2=control B2

20.4= humidity B4

20.8= steam generator B5

(e.g. 20.12 = B4 + B5)

Service 21 (only

error history)

Voltage and current moni-

toring on PCB

1- 18V from T1, 2 - 12V on PCB, 4 - high current MMI, 8 - high current Drain

valve M7, 9 - high current humidity valve Y5

Service 25 No water ow detected

during CleanJet

during CleanJet+Care the fan motor does not an increase in power demand

when water hits the fan wheel. -

check water pressure, water supply, moistening valve and nozzle and CDS

sensor.

GN racks or trolley properly inserted.

Service 26 Drain valve does not nd

the open position

Micro switch drain valve not working properly

Initialise drain valve in basic settings, water, Cleanjet/Care, drain valve

time ration should be 1/4 : 3/4, e.g 9:27 sec or 6:18 sec.

test drain valve in function test

if drain valve not working change drain valve assembly

Service 27 Drain valve does not nd

the closed position

Micro switch drain valve not working properly

Initialise drain valve in basic settings, water, Cleanjet/Care, drain valve

time ration should be 1/4 : 3/4, e.g 9:27 sec or 6:18 sec.

test drain valve in function test

if drain valve not working change drain valve assembly

Service 28 Thermocouple B5 above

180°C

Indication goes o when temperature below 110°C (230°F)

check if steam element is covered in scale.

Service 29 PCB temperature above

85°C (185°F)

Check air lter, cooling fan and control panel gasket

Check for external heat sources

1 - 29

Loading...

Loading...