— English Variomat Touch — 09.09.2022-Rev. C

3 Secondary vessel

4 Reflex rapid-action coupling R 1 x 1

5 Primary vessel

6 Primary vessel connection set

7 Typical representation of the control unit

EC Degassing line

• Gas-rich water from the system

• Degassed water to the system

LIS "LIS" level sensor

WC Make-up pipe

MAG Pressure expansion vessel

If required, install a diaphragm expansion vessel MAG ≥ 35 litres (Reflex N, for

example). It reduces the switching frequency and can be also used in the

individual protection of the heat generators. According to DIN / EN 12828, the

installation of valves between the device and the heat generator is required for

heating systems. Otherwise secure locking mechanisms must be fitted.

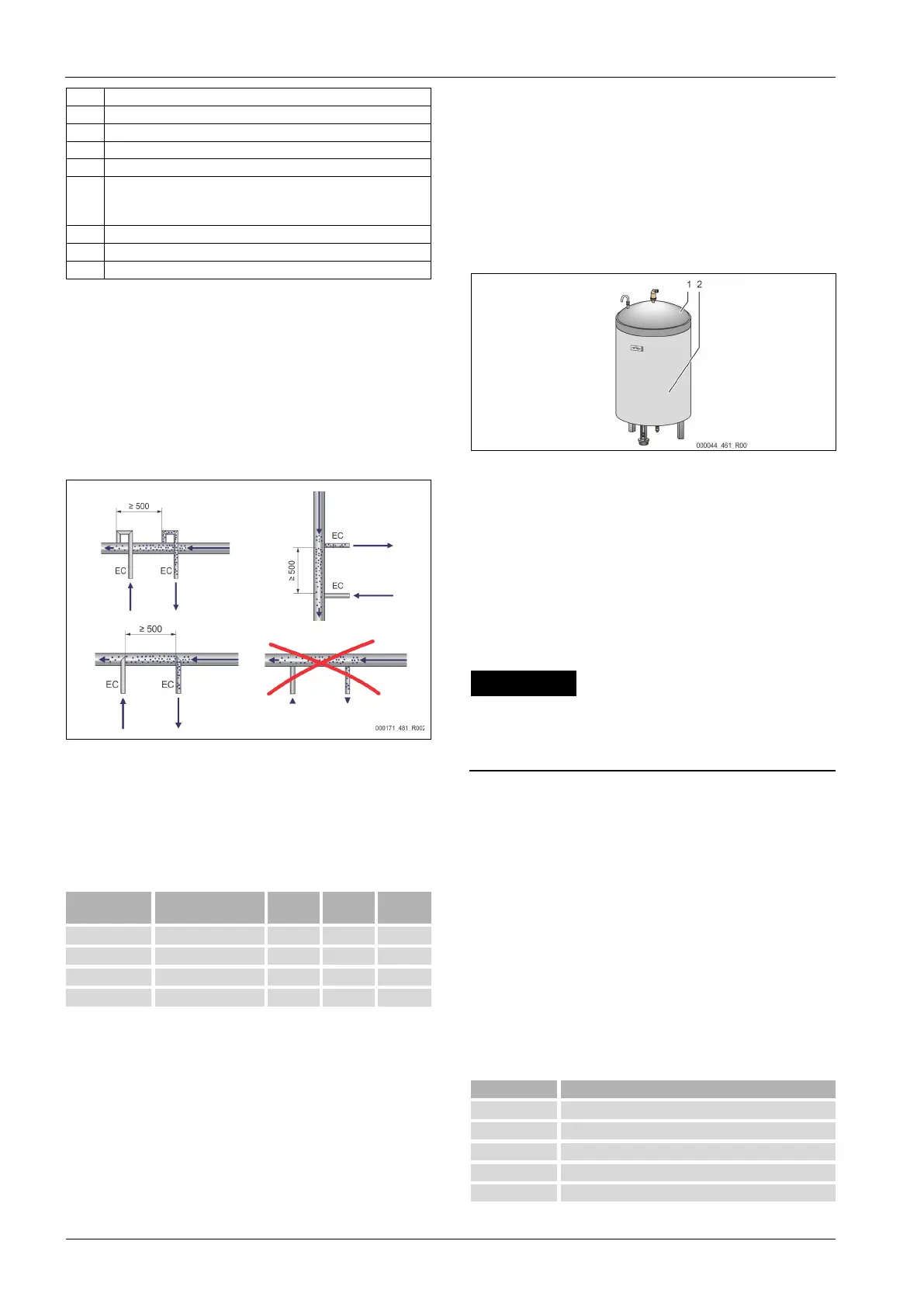

"EC" expansion lines

Because of the degassing function, you must install two "EC" expansion lines.

• One line to the system for the gas-rich water.

• One line to the system for the degassed water.

The "DN" nominal connection diameter for the "EC" expansion lines must be

designed for the "P

0

" minimum operating pressure.

Calculation P

0,

8.2 "Variomat switching points", 40.

The "DN" nominal connection diameter applies to an expansion line length of up

to 10 m. Beyond this length, select the next larger dimension. Integrate with the

"V" main flow volume of the system. Viewed in the system flow direction, the

gas-rich expansion line must be connected upstream of the expansion line

transporting the degassed water.

Ensure that particulate dirt cannot enter and thus creating an overload of the

"ST" dirt trap. Connect the "EC" expansion lines according to the following

installation variants.

Minimum operating

pressure p

0

(bar)

-1 X --- ---

-2/35 X --- ---

-2 ≤ 3.5 --- X ---

-2 > 3.5 --- --- X

Note!

The water temperature at the connection point of

the "EC" expansion

lines must be in the range of 0 °C to 70 °C. The use of auxiliary vessels

does not increase the range of use. Because the thermal protection is

not ensured due to the flow during the degassing phase.

7.3.4.2 Make-up line

If you don't connect the automatic water make-up, you must close the

connection of the "WC" make-up line with a R ½ " blind plug.

• Prevent a potential device fault by ensuring manual water make-up.

• Install at least one "ST" dirt trap with a mesh size ≤ 0.25 mm close

upstream to the make-up solenoid valve.

– Install a short line between the "ST" dirt trap and the solenoid valve.

Use a pressure reducer in the "WC" make-up line if the idle pressure

-up water from the potable water system, you may need

the Reflex Fillset for the "WC" make

-up line, 4.6 "Optional equipment

", 30.

Reflex make-up systems such as Reflex Fillset are designed for

make-up lines with a flow rate < 1 m³/h.

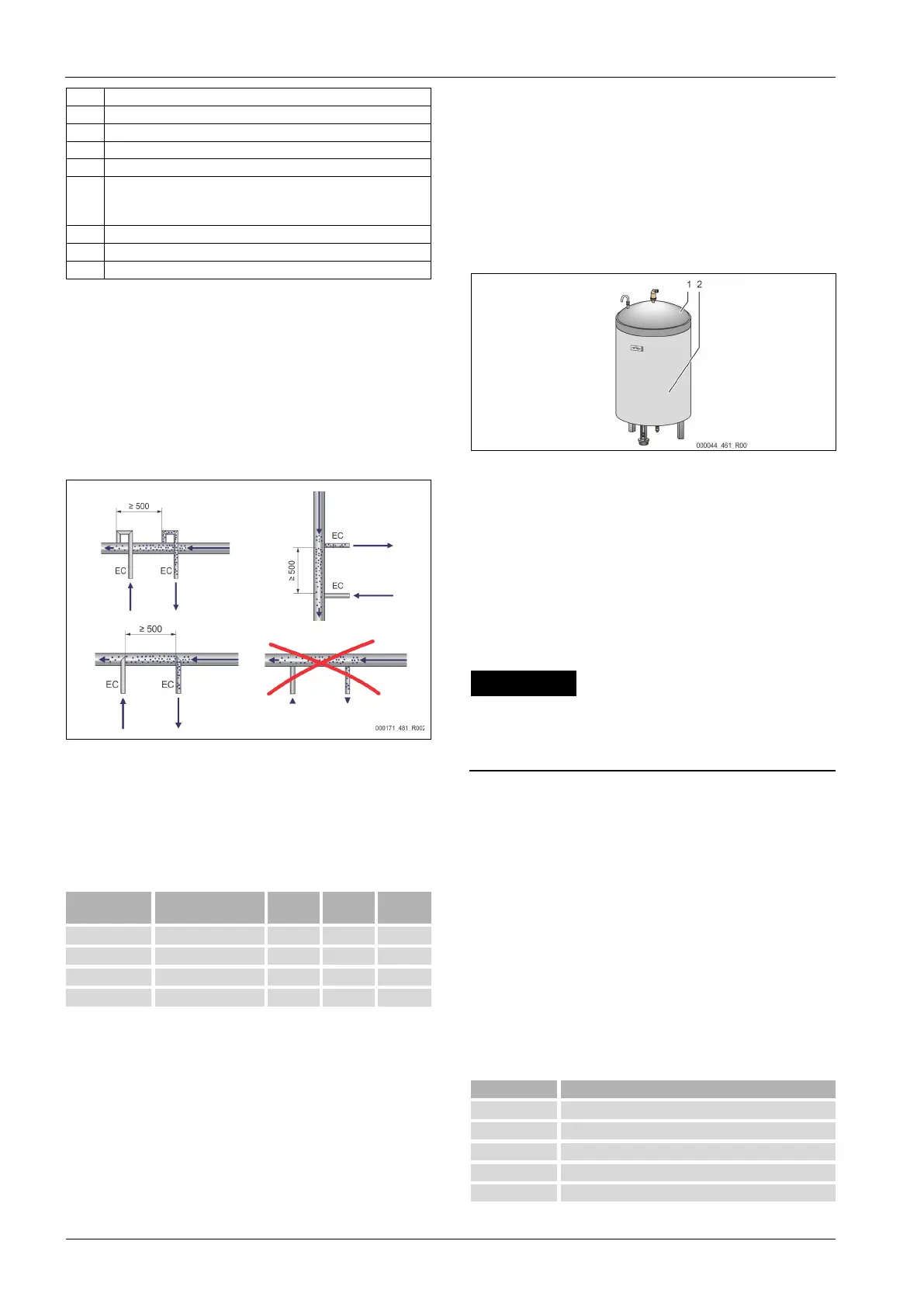

7.3.5 Fitting the thermal insulation

Install the optional thermal insulation (2) around the primary tank (1) and close

the insulation with the zip fastener.

Note!

For heating systems, insulate the primary tank and the "EC" expansion

lines against heat loss.

Thermal insulation is not required for either the primary tank top

-site, install thermal insulation when condensate forms.

7.3.6 Installation of the weight measuring cell

Damage to the pressure load cell due to unprofessional installation

Incorrect installation may result in damage to the "LIS" level sensor,

malfunctioning and incorrect measurements from the pressure load cell.

• Comply with the instructions regarding the installation of the pressure

The "LIS" level measurement uses a pressure load cell. This pressure load cell is to

be installed after the primary vessel has been placed at its final position, 7.3.3

"Tank installation", 34. Comply with the following instructions:

• Remove the transport safety device (squared timber) at the mounting foot

of the primary vessel.

• Replace this transport safety device with the pressure load cell.

– The pressure load cell can optionally be fastened to the mounting

foot of the primary vessel using the supplied screws. However,

fastening is not necessary.

• Avoid shock-type loading of the pressure load cell by, for example,

subsequent alignment of the vessel.

• Use flexible hoses to connect the primary vessel and the first secondary

vessel.

– Use only the supplied connection sets, 7.3.3 "Tank installation",

34.

• Perform a calibration of the filling level when the primary vessel is aligned

and fully emptied, 8.6 "Parametrising the controller in the Customer

menu", 42.

Standard values for level measurements:

200 l 0 – 4 bar

300 – 500 l 0 – 10 bar

600 – 1000 l 0 – 25 bar

3000 – 5000 l 0 – 100 bar

Loading...

Loading...