Rexroth IndraDrive C Electrical Data 6-19

DOK-INDRV*-HCS02.1****-PR02-EN-P

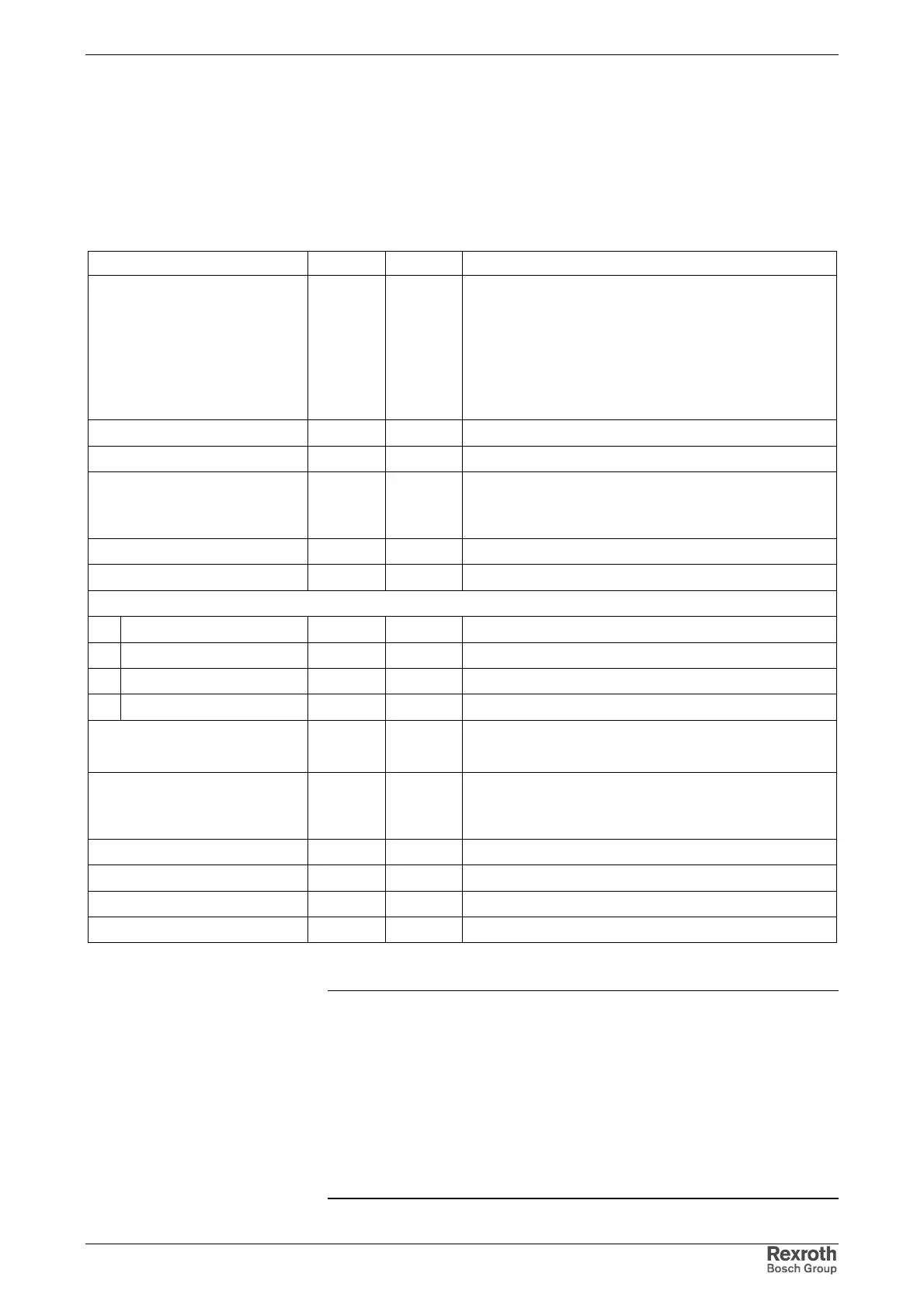

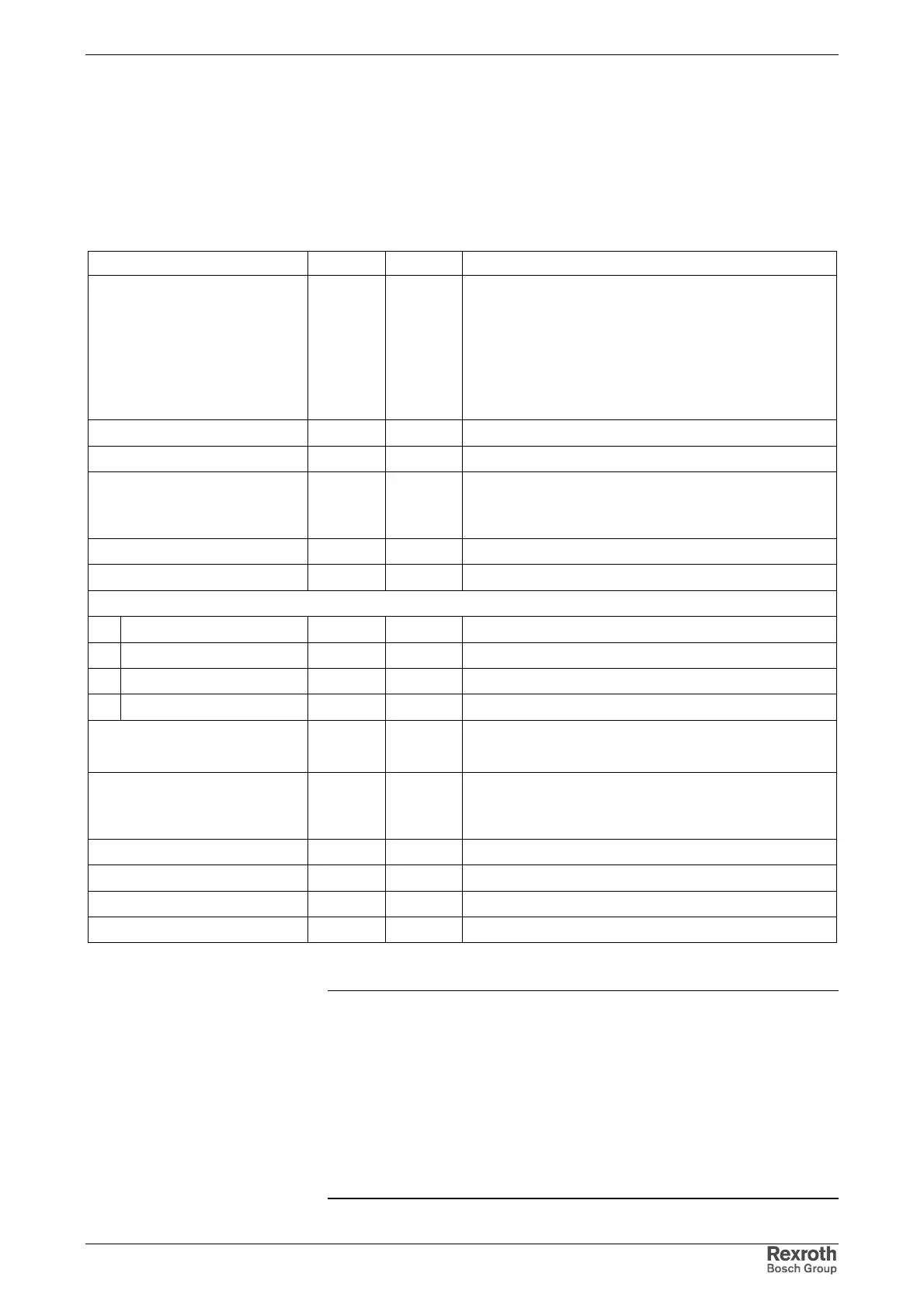

Devices with Internal Control Voltage Supply Generation from DC bus

(HCS02.1E-W00xx-NNNV)

The internally generated control voltage is used for stand-alone supply of

the drive controller or buffering in case the external 24V supply fails. It is

not used for supplying motor holding brakes.

(Information at ambient temperature of 25 °C)

Designation Symbol Unit Value

control voltage U

N3

V

• 24 ±20%

(when no motor holding brake is used)

• If motor holding brakes are to be supplied, observe

the data of the motor documentation. The following

values are normally sufficient:

24 ±5% with motor cable length <50 m

26 ±5%

with motor cable length >50 m

max. ripple content w - mustn't exceed the control voltage range

max. allowed overvoltage U

N3max

V 33 (max. 1 ms)

max. charging current I

EIN3

A2.8

plus charging current of control section (see Project

Planning Manual IndraDrive Control Sections)

max. pulse duration of I

EIN3

t

EIN3Lade

ms 15

max. input capacity C

N3

mF 1.2 * 0.47

power consumption*:

HCS02.1E-W0012 P

N3

W12

HCS02.1E-W0028 P

N3

W14

HCS02.1E-W0054 P

N3

W23

HCS02.1E-W0070 P

N3

W23

internally generated control

voltage

U

N3

V

24 ±10%

(not used for supplying the motor holding brake)

output power

for required power of control

section CS* and power section

W70

power dissipation W 25

short-circuit strength present

overload withstand capability present

overtemperature protection present

Fig. 6-19: Control voltage -***V

Note: Overvoltages of more than 33 V have to be derived by

measures in the electrical equipment of the machine or

installation. This includes:

• 24-Volt mains sections that reduce incoming overvoltages

to the allowed value.

• Overvoltage limiters at the control cabinet input that limit

existing overvoltages to the allowed value. This also

applies to long 24-Volt lines that have been laid in parallel

with power and mains cables and can absorb overvoltages

caused by inductive or capacitive coupling.

Loading...

Loading...