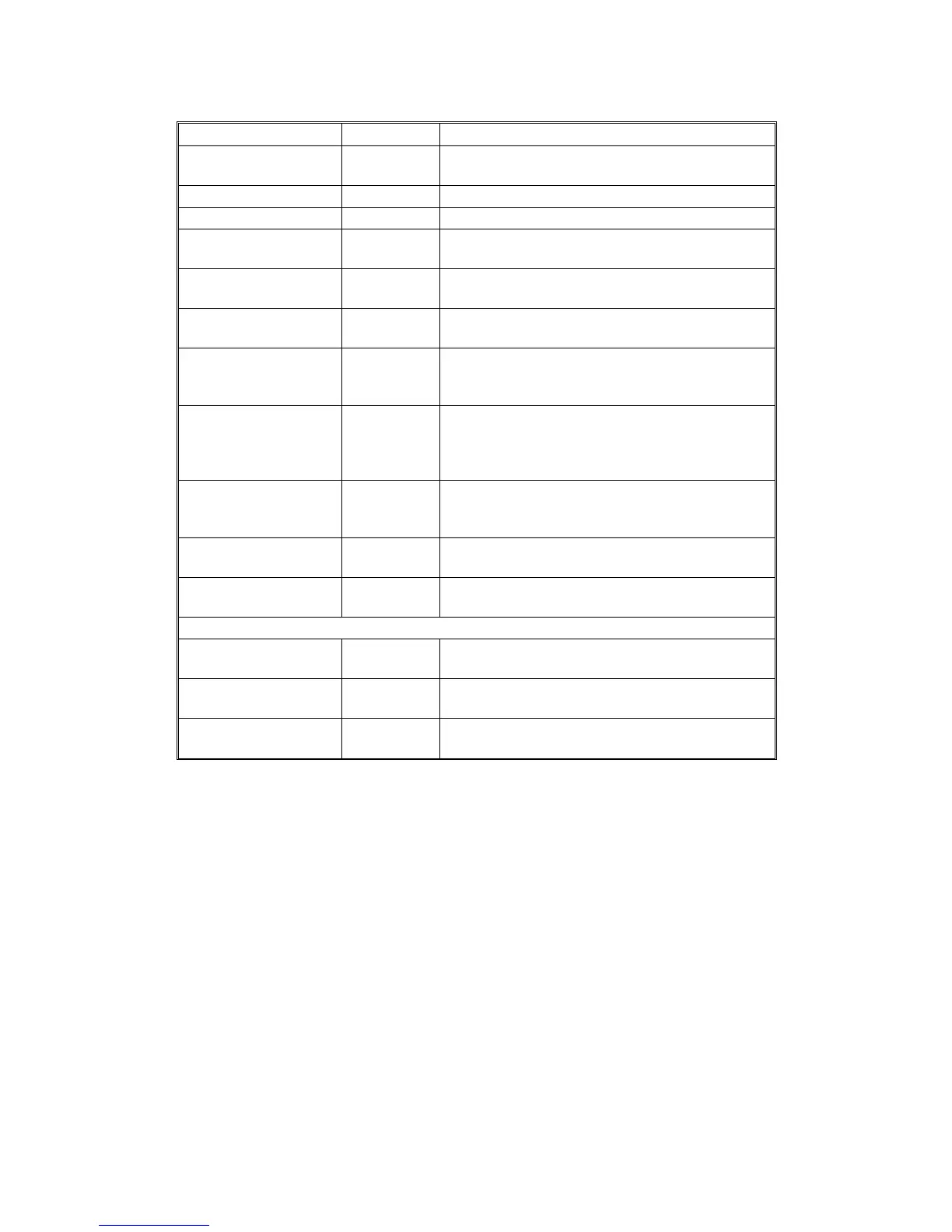

1.3 PERIODIC INSPECTION TABLE (EVERY 6 MONTHS)

Item/Location Step Inspection Standard

Original platen cover Cleaning Wipe off any stains with a soft cloth dampened

with ethyl alcohol.

Exposure glass Cleaning Wipe with a dry cloth.

Mirror/Sub mirror Cleaning Use a blower brush.

Platen roller Cleaning Wipe off paper powder with a cloth dampened

with water.

Sensors Inspection

and cleaning

Check the performance of all the sensors.

Remove stains from sensors with dry cloth.

Press roller Cleaning Wipe off the ink and paper powder with cloth

dampened with ethyl alcohol.

Drum surface Cleaning Wipe off the paper powder and ink which is forced

out from the trailing edges of the masters using a

cloth dampened with ethyl alcohol.

Master feed and

delivery

Inspection The master should be properly fed and clamped,

without generation of skew, folding, etc. The

master should also be properly delivered without

jam.

Paper feed and delivery Inspection Print several sheets of paper to ensure that paper

is fed smoothly and delivered, without generation

of skew, folds, wrinkles, etc.

Second paper feed

rollers

Cleaning Wipe off ink and paper powder with a cloth

dampened with alcohol.

Original transport rollers Cleaning Wipe off paper powder with a cloth dampened

with water.

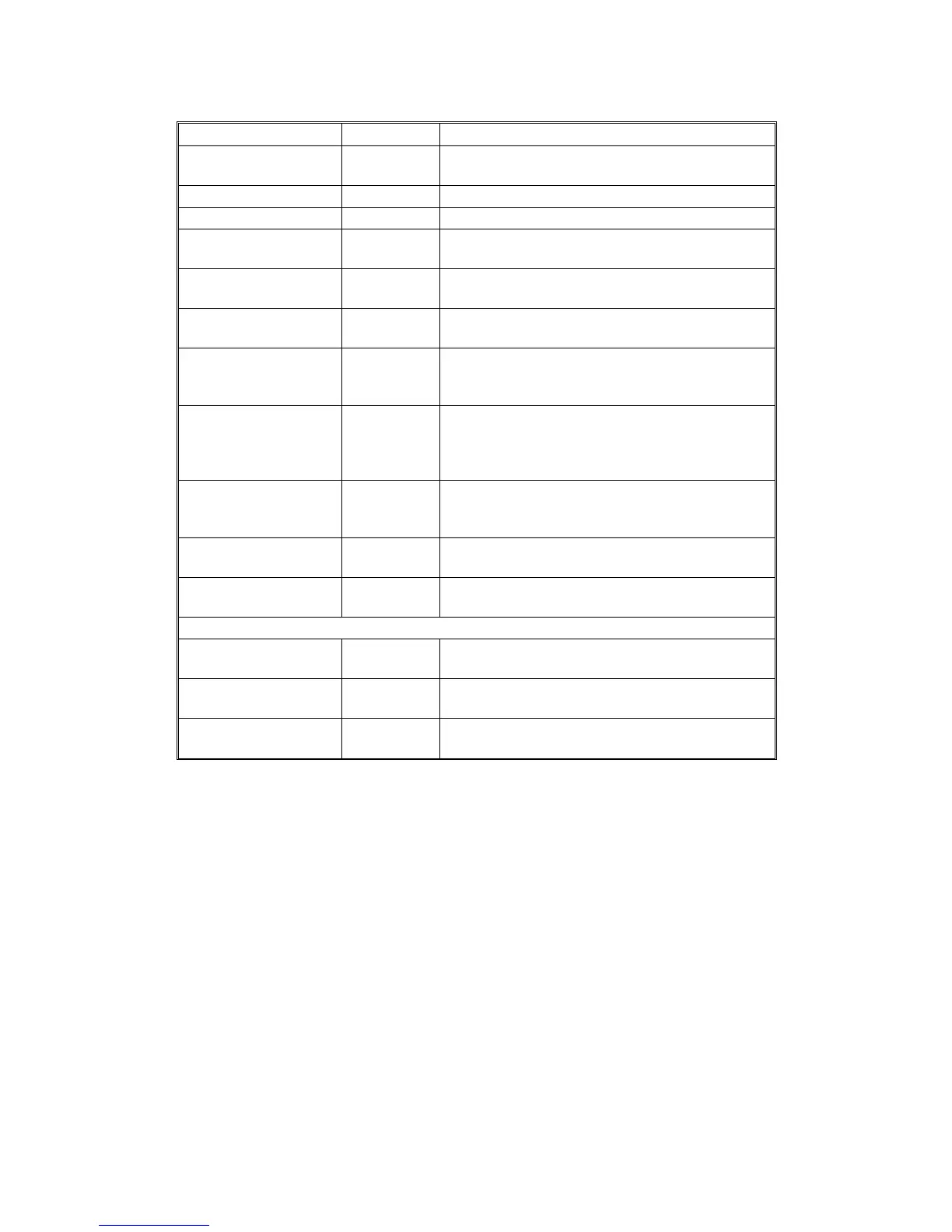

ADF

Pull-out roller Cleaning Wipe off paper powder with a cloth dampened

with water.

Original feed roller Cleaning Wipe off paper powder with a cloth dampened

with water.

Separation blade Cleaning Wipe off paper powder with a cloth dampened

with water.

C224 4-2 SM

Loading...

Loading...