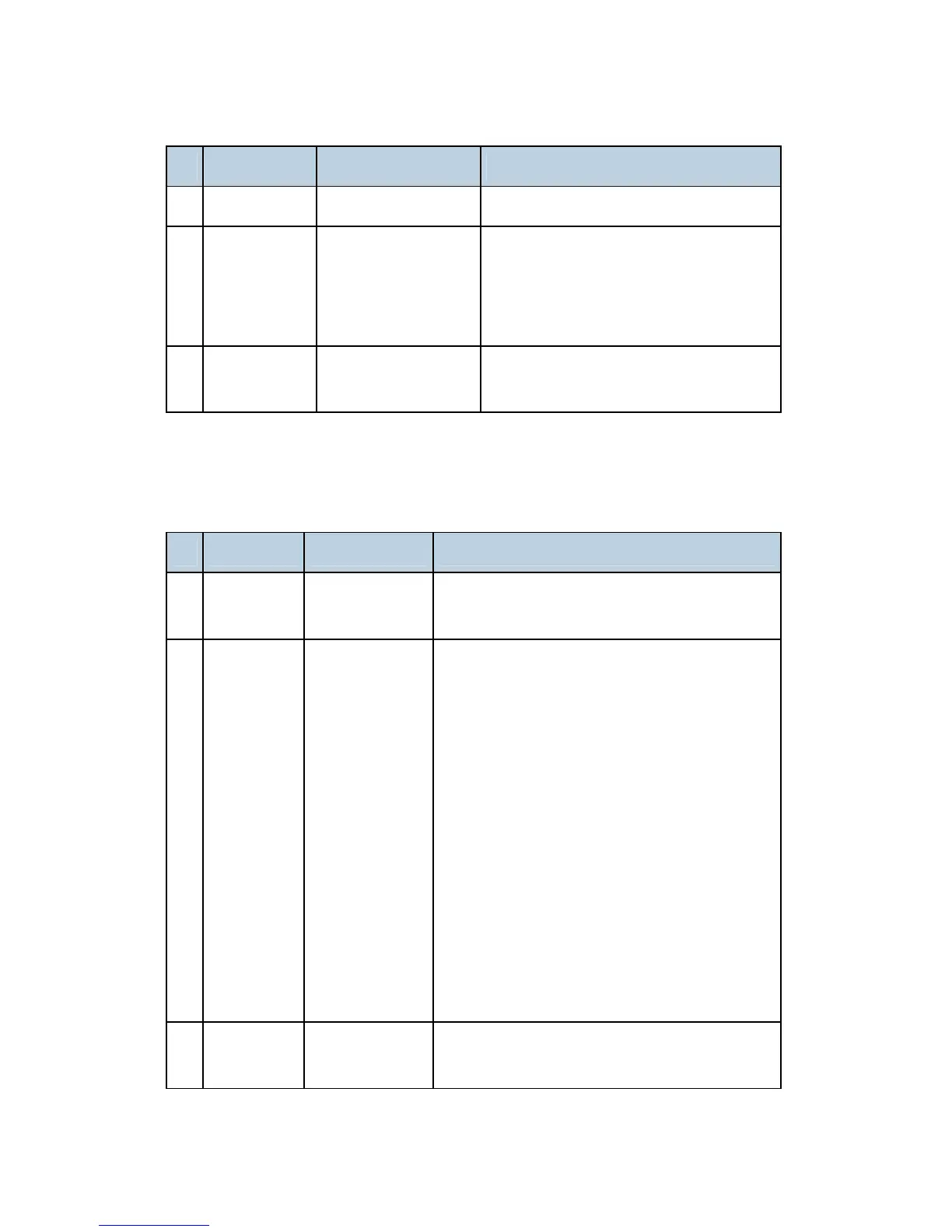

Process Control Error Conditions

D037/D038/D040/D041 5-4 SM Appendix

No. Result Description Possible Causes/Action

Same as 53

59

Sampling data

error during

gamma

correction

Not enough data can

be sampled during the

gamma correction.

ID sensor pattern density is too high

or low.

Hardware defective

Same as 53

99

Unexpected

error

Process control fails.

Power Failure

Check the power source.

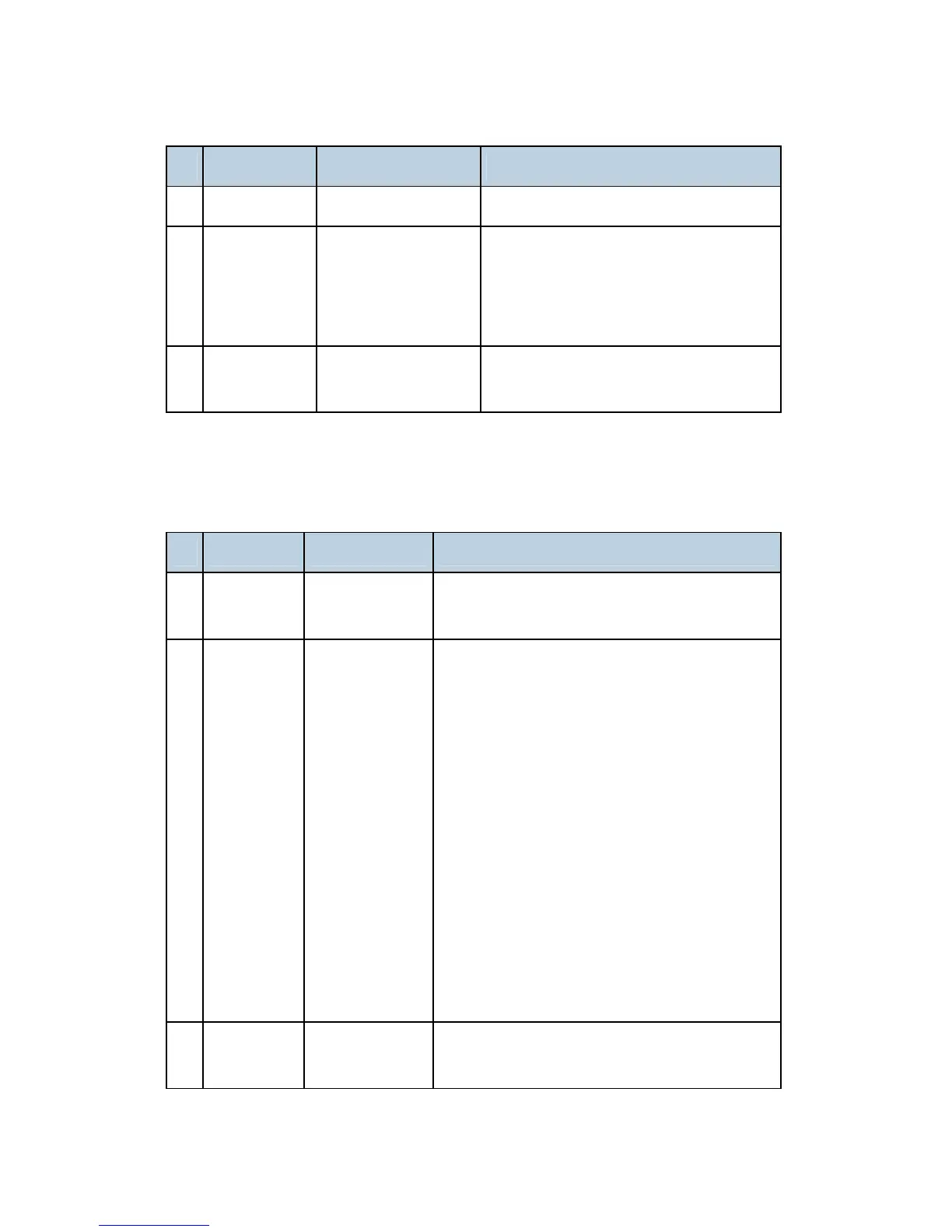

Vsg Adjustment Result

SP3-325-001 to -010 (Vsg Adjustment Result)

No. Result Description Possible Causes/Action

1 O.K

Vsg adjustment

is correctly done.

-

2

ID sensor

adjustment

error

Vsg cannot be

adjusted within

4.0 ±0.5V.

Dirty ID sensors (toner, dust, or foreign

material)

Dirty image transfer belt

Scratched image transfer belt

Defective ID sensors

Poor connection

Defective BCU

1. Clean the ID sensors.

2. Check the ITB cleaning unit. Clean or

replace the image transfer belt.

3. Replace the image transfer belt.

4. Replace the ID sensors.

5. Check the connection.

6. Replace the BCU board.

3

ID sensor

output error

ID sensor output

is more than

Defective ID sensors

Poor connection

Loading...

Loading...