Robotiq Screwdriving Solution - Instruction Manual

8.2.2.Lubrication

MAINTENANCEINTERVAL REQUIRED TOOLS REQUIRED PARTS

Monthly

l

Non-curing silicone-based lubricant

l

T10 Torx

®

screwdriver

None

Caution

Do not use petroleum-based productsfor lubricating the Screw Feeder parts.

Only use silicone-based lubricants.

1. Using a T10 Torx

®

screwdriver, remove the two top screwsfrom the head clearance plate assembly.

2. Remove the whole assembly by sliding the plate forward and then upward.

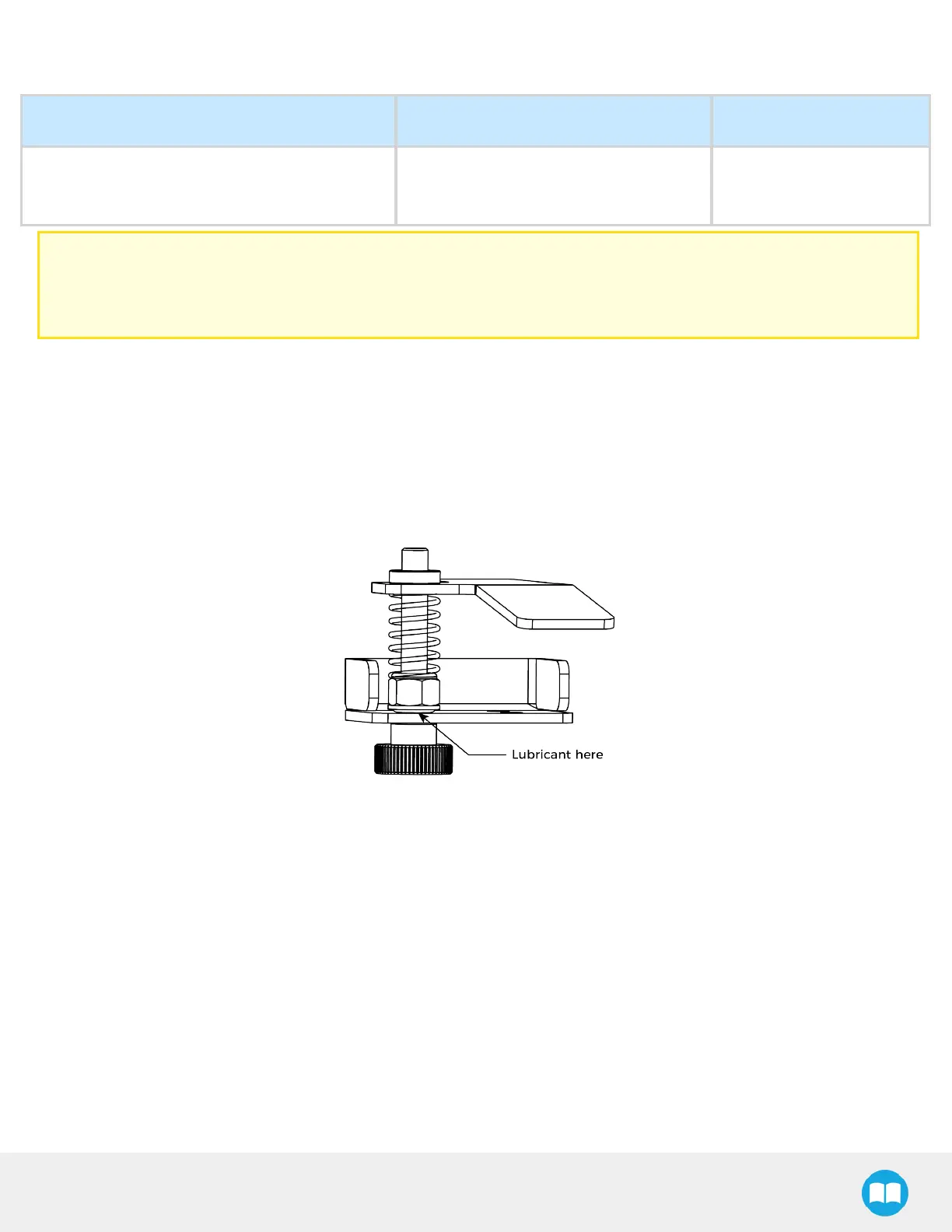

3. Holding the assembly upside down, add a drop of non-curing silicone-based lubricant at the base of the pivot (behind the

flat washer).

4. Work the adjustment knob to spread the lubricant evenly.

5. Wipe off the excess lubricant before reassembling the head clearance plate.

Fig. 8-2: Head Clearance Plate Lubrication.

6. Open the Screw Feeder’scover.

7. Push the brush assembly horizontally; doing so will reveal the adjustment screw mechanism.

8. Add a drop of lubricant between the flat washer and the main brush shaft.

9. Work the adjustment knob to spread the lubricant evenly

10. Wipe off the excess lubricant.

81

Loading...

Loading...