Robotiq Screwdriving Solution - Instruction Manual

Feeder can cause motor block-

age.

3. Review the adjustments of the

Screw Feeder; for instance, a

brush adjustment set too low

can cause motor blockage.

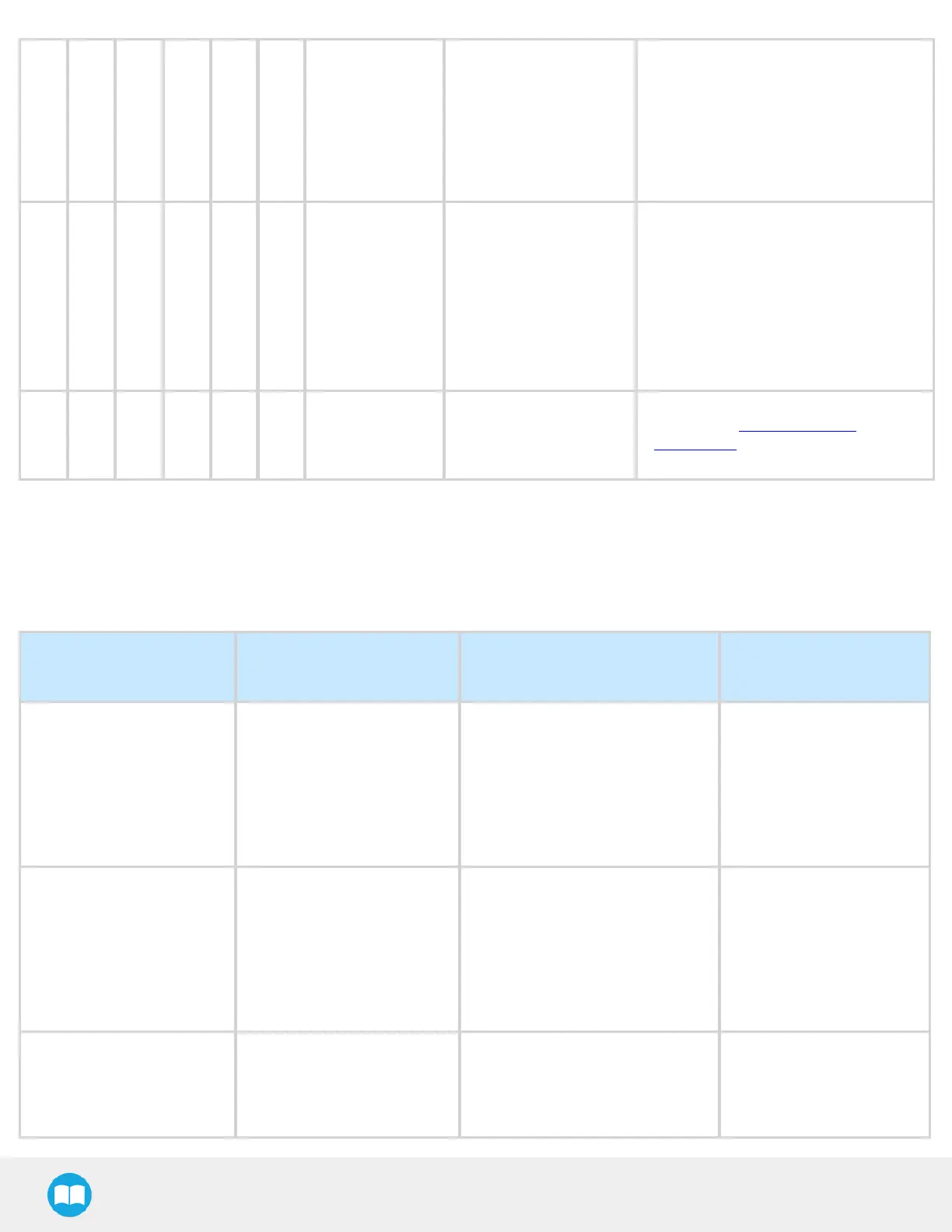

B B B R R -

Major general

error

l

Undervoltage

l

Over temperature

Make sure the Screw Feeder is

powered with the appropriate power

supply.

Make sure the Screw Feeder isnot too

hot.

If the fault persists, call Robotiq

support.

B B B R R R

Major

application

error

Internal major problem

Contact the Robotiq support

department.

Refer to the Error Management section for more troubleshooting guidance.

10.3.Error Management

10.3.1.Robotiq Screwdriver

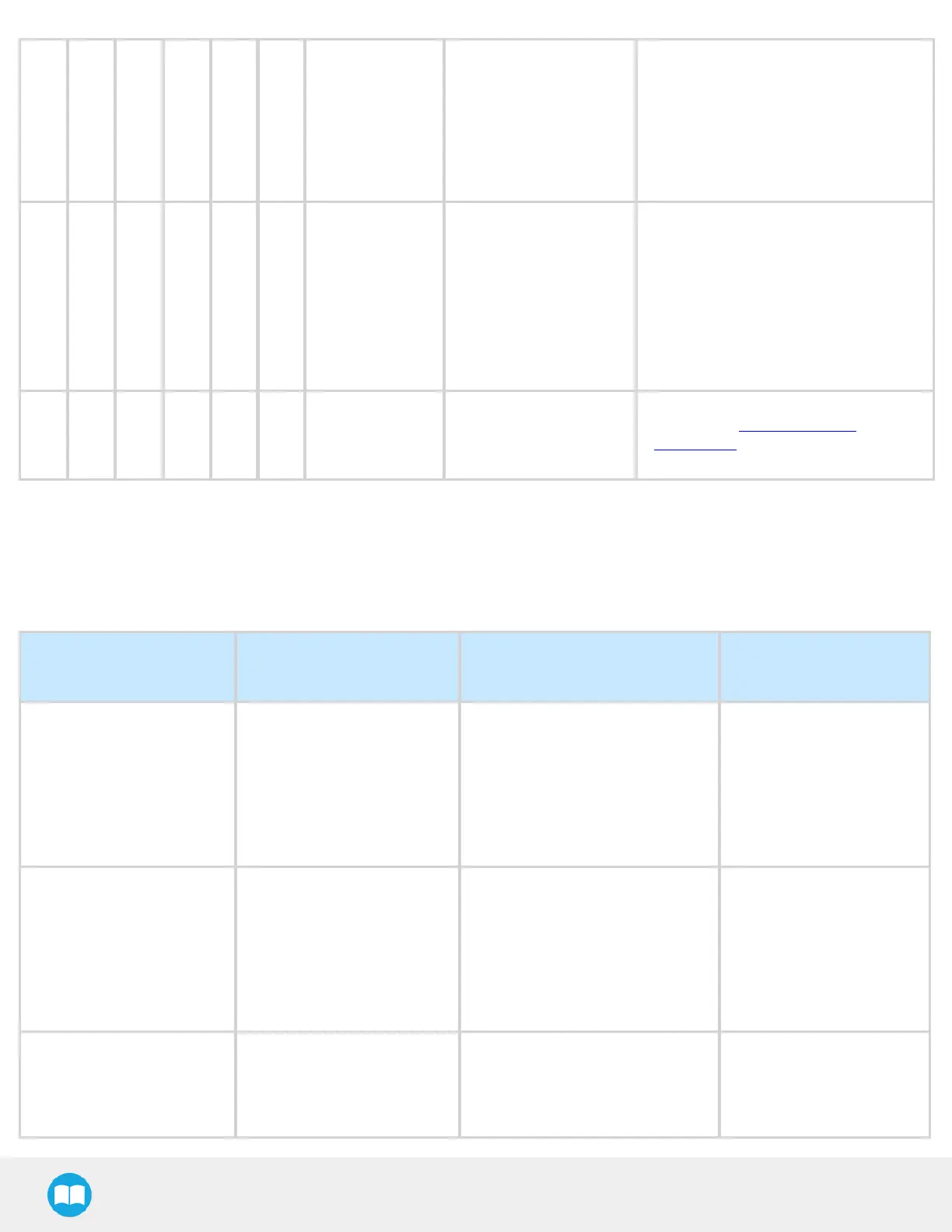

ERROR DESCRIPTION POTENTIALRECOVERY

RELATED SCRIPT

FUNCTIONS

Screw not detected

The Screwdriver isat the

retract position after going

to the pick position, and the

screw is either not detected

or misaligned.

Dispose of the dropped screw, if

applicable, and perform the

picking action again.

Vacuum off

rq_screw_vacuum_off()

Validate the presence of

the screw

rq_get_screw_detection()

Screw dropped

A screw had been detected,

but its presence is not

detected anymore.

Retrieve the dropped screw, and

either 1) halt the program and

wait for an operator to solve the

issue or 2) dispose of the

dropped screw, if applicable, and

perform the picking action again.

Vacuum off

rq_screw_vacuum_off()

Validate the presence of

the screw

rq_get_screw_detection()

Torque value reached

before reaching final

position

The Screwdriver has

performed the screwing

action but has not reached

the final position due to

1. Maintain the screwdriving

bit in the screw’s drive,

unscrew, and perform the

screwing action again on

Unscrew

rq_auto_unscrew()

88

Loading...

Loading...