10.Troubleshooting

10.1.Screwdriver Behavior

The Screwdriver goesup and downbefore a successful pick

This indicates that the screw detection via vacuum action isnot optimal.

Please refer to the Vacuum Coupler Adjustment section and optimize the adjustment of the vacuum coupler accordingly.

Screwsare not picked properlyand/orconsistently

l

Make sure you are using the right screwdriving bit.

l

Make sure you are using the vacuum sleeve that corresponds to the screwdriving bit. You can use a different sleeve if it appears

to be more suitable for your application.

l

Make sure the adjustment of the vacuum coupler allowsfor the appropriate holding of the screw against the vacuum sleeve.

Please refer to the Vacuum Coupler Adjustment section and optimize the adjustment of the vacuum coupler accordingly.

l

Make sure the picking position defined is aligned and at a perfect 90-degree angle perpendicular to the Screwdriver and screw-

driving bit. Please refer to the Picking Screw section to orient the device using the ActiveDrive feature.

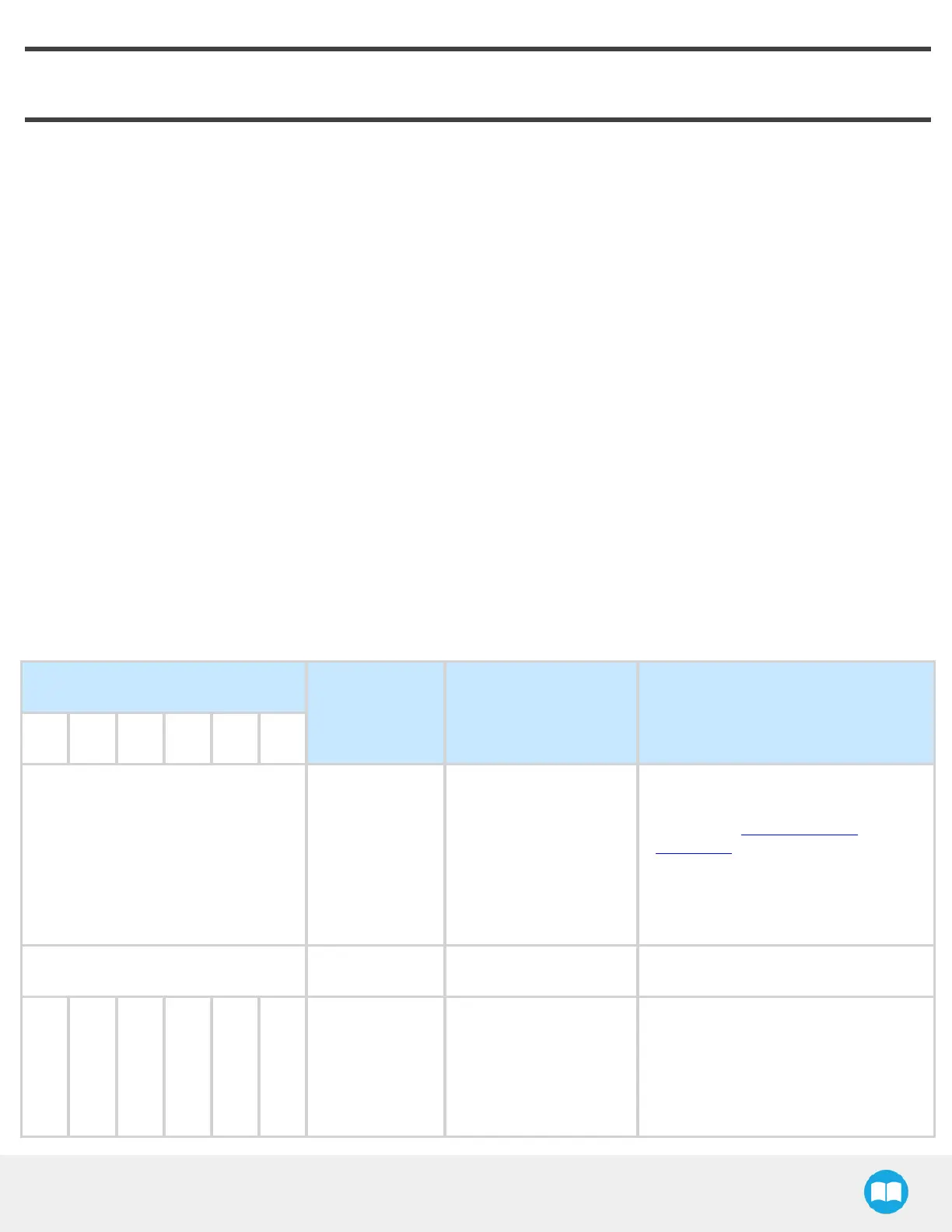

10.2.Screw Feeder Behavior

The Screw Feeder uses a periodic, equally timed, 6-pulse Red (R) and Blue (B)code to indicate its operating state. In normal

operating conditions, the Screw Feeder’sstatusLED is solid blue and it turns green when communicating via USB. Other statuses

and faults are detailed in the following table:

STATUSLED

DESCRIPTION POSSIBLECAUSE SOLUTION

1 2 3 4 5 6

SOLID BLUE AND RED (PURPLE) Booting

l

The device is going

through its power on

sequence (no more

than 2 seconds).

l

The device cannot

load the firmware pro-

gram.

Upgrade the Screwdriver’s firmware

(contact the Robotiq support

department for assistance).

If the problem persists, call Robotiq’s

support department.

SOLID BLUE No fault Normal operation -

- - - R R R

Minor

application

error

Wheel and/or

singulator motor

blockage

1. Check for screw blockage

around the reclaiming wheel and

singulator; the screwsmay have

fallen in unwanted positions.

2. Too many screws in the Screw

Robotiq Screwdriving Solution - Instruction Manual

87

Loading...

Loading...