Robotiq Screwdriving Solution - Instruction Manual

5.1.3.Pick and Screw Sequence

Caution

Prior to engaging a pick and screw sequence, make sure that the Screwdriver is equipped with the appropriate

screwdriving bit and vacuum sleeve, and that the coupler assembly iscorrectly adjusted to ensure a successful screw

detection and picking sequence.

Picking Screw

1. Insert a Pick screw node in the program tree. Please refer to the Command Windowsection should you need instructions on

how to do so.

2. If not automatically selected, select the digital inputsof the Screw Feeder. Please refer to the Screw Feeder Signalssection

should you need to rename the inputsaccording to the signal they are transferring.

3. Remove the vacuum sleeve covering the screwdriving bit.

Caution

Make sure the tool is perpendicular to the Screw Feeder’sSurface.

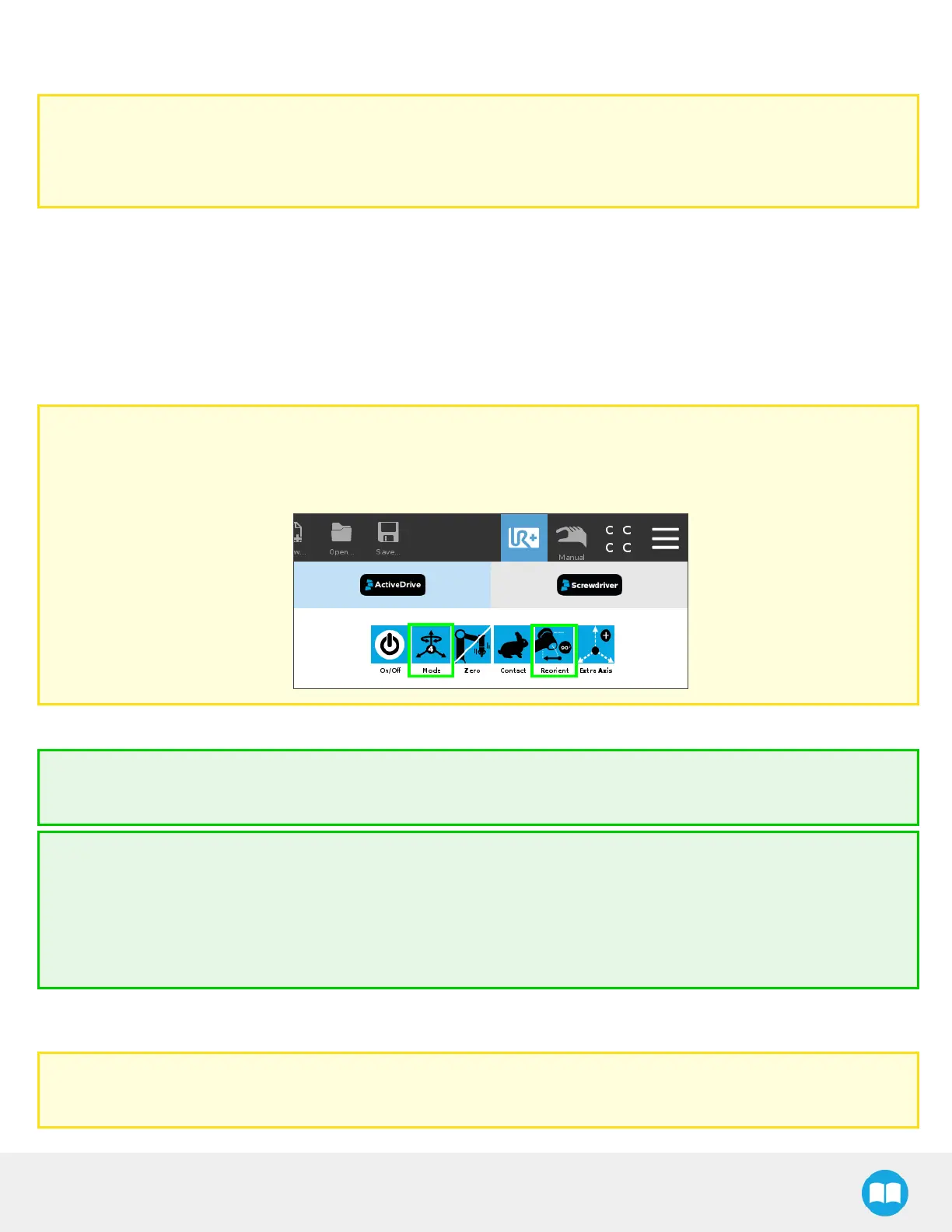

You can use the ActiveDrive feature to reorient the tool at 90 degrees and lock the motion in 4 degrees of freedom.

4. Using the ActiveDrive feature, move the tool to bring the screwdriving bit as close as possible to the screw head.

Tip

Use the Contact mode of the ActiveDrive feature to move the tool slowly and precisely.

Tip

Reduce the speed of the robot to the minimum using the slider in the PolyScope interface.

You will need to stop the ActiveDrive feature to do so.

The user can also rotate the Screwdriver’s body above the screw drive for the screwdriving bit to be as centered as

possible; screwdriving bitsare often not perfectly straight.

5. Slowly bring the screwdriving bit asclose aspossible to the screw head; Robotiq recommends placing the very tip of the

screwdriving bit flush with the top of the screw head. Thisoptimizesthe vacuum action for a straight screw picking.

Caution

The screwdriving bit must not reach and apply pressure at the bottom of the screw head drive.

58

Loading...

Loading...