ed. All in all a very recommendable drive for the ELS. The disadvantage here, too, is the higher

price.

The ELS generates step and direction signals for motor drivers. A step pulse drives the stepper

motor 1/200 revolution further, the direction signal determines in which direction the motor

rotates. In this way, the ELS can precisely control the motors. If the

motor is mounted on the lead screw, the ELS can precisely control

the position of the carriage.

Normal stepper motors make 200 full steps per revolution, but the

stepper motor output stages can divide these whole steps into small-

er parts, so-called microsteps. This starts with half steps and ends

with very small step widths. The smaller the sub-steps, the quieter

and smoother the motor runs, the disadvantage being that the motor loses torque the smaller

the step widths become, and that the controller has to deliver more impulses for this.

With the ELS, we use steps on the Z axis ½ or ¼, i.e. 400 or 800 steps per revolution. More is

not necessary and only unnecessarily limits the maximum possible feed rate. We can also use

even ner steps on the X axis.

Motorcoils

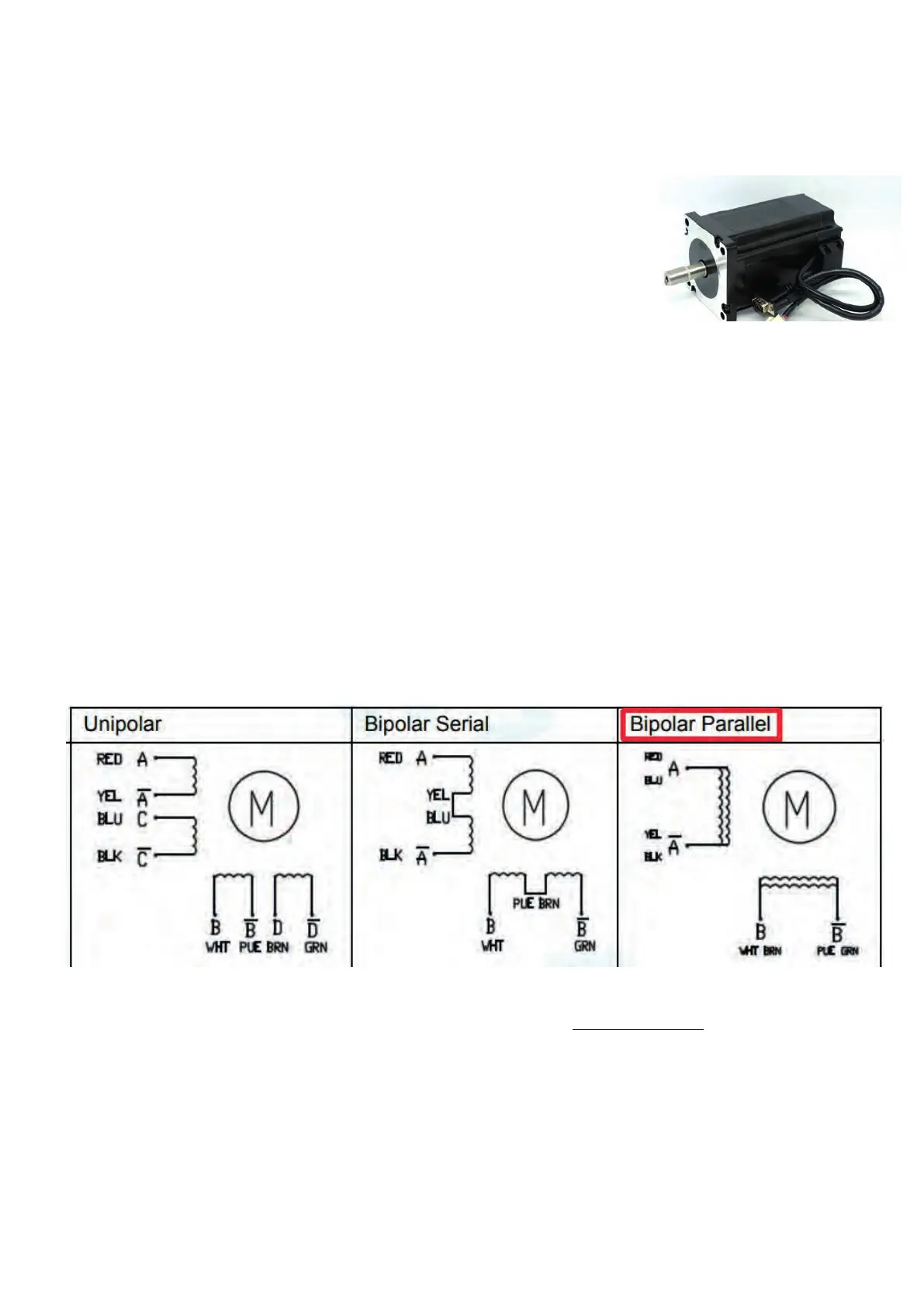

Stepper motors and hybrid servo motors have two, three or four coils that can be connected

to the output stage in dierent ways. Most stepper motors have 8 wires, for each coil 2. These

coils can now be operated in series or parallel. One method is unipolar, which is quite rare

since most power ampliers support bipolar serial or parallel operation:

There are advantages and disadvantages for each method, you can write books about it, so

we make it easy here: With the ELS we connect the motors Bipolar Parallel. This circuit gets the

most torque and the highest speed out of the motors.

15

Loading...

Loading...