UNDERCUT

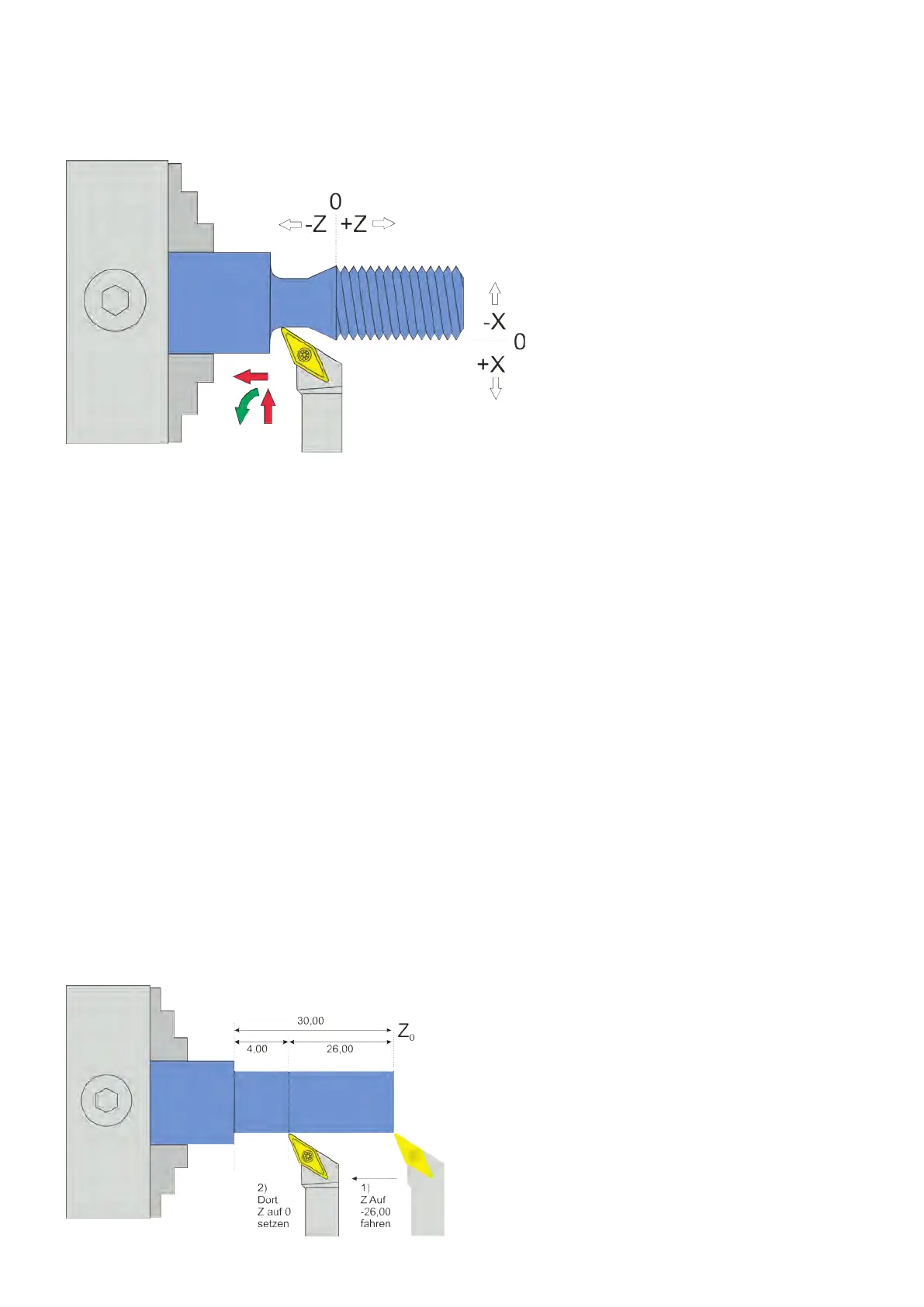

This mode is used for the automatic turning of undercuts according to DIN 76-1. Turning is

done with pointed inserts, e.g. type VCGT..

An undercut is optimal at the bottom of threads. The undercut according to DIN 76-1 is initiated

by a 30° incline, followed by a straight section that ends in a radius.

The dimensions are entered by changing the depth (XP). Since undercuts are usually used in

threads, select the depth by the depth of the thread and add 0.5mm. The length of the under-

cut will then be calculated automatically to obtain the shortest possible undercut. If you want

the undercut to be longer than the automatic has calculated, you can switch to ZP and simply

increase the length.

Before the start of the cut, the number of passes is shown again, which can be changed quickly

with the knob as usual.

Example:

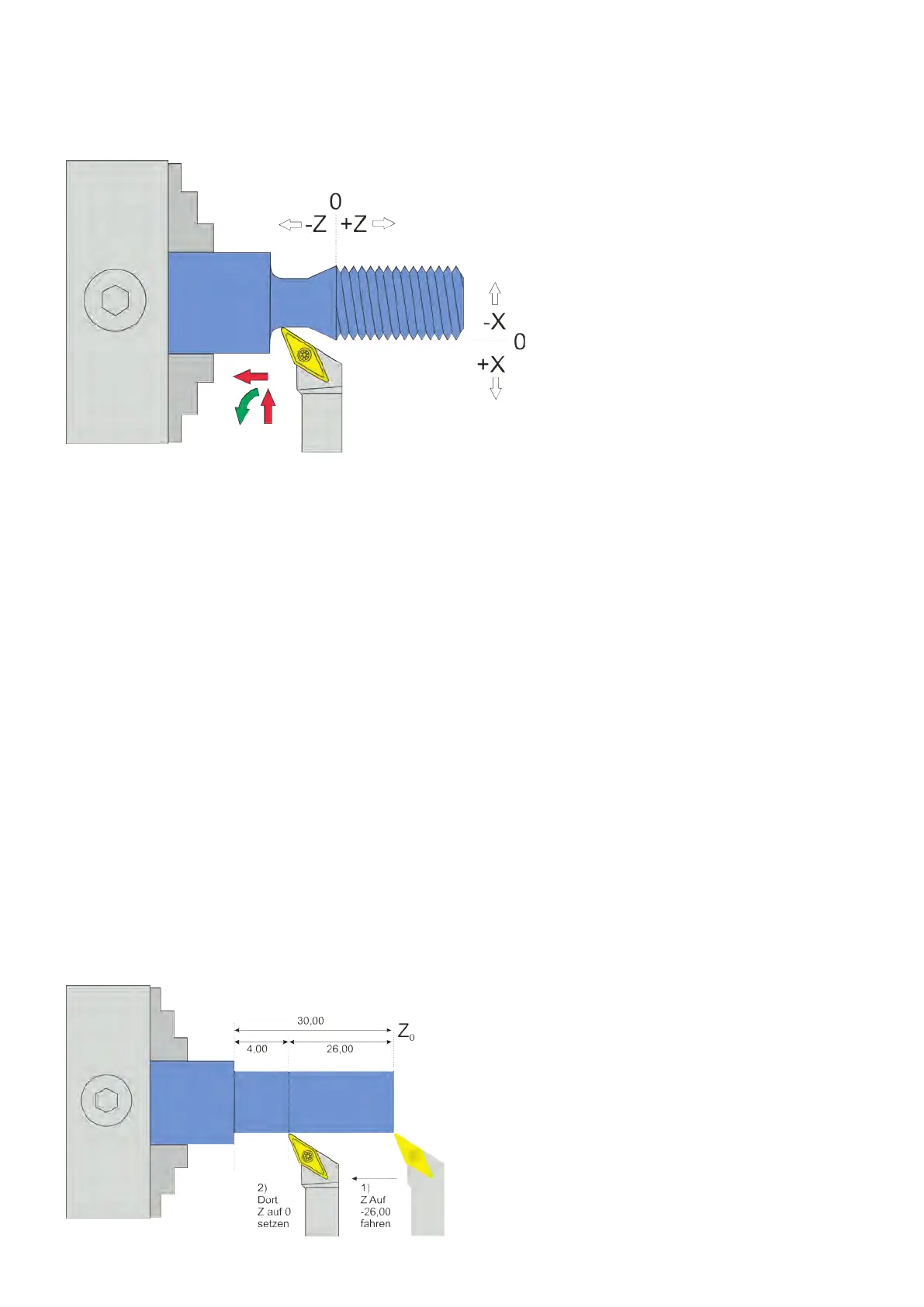

A bolt end has been turned and is 30 mm long. A thread is to be cut with 0.97mm thread depth.

We set the depth of the undercut to XP=-1,50mm. The length is then calculated by the ELS to

ZP=-3.47mm.

So that we can place the undercut exactly at the end of the bolt, we increase the length to -4.00

mm. We then move from the zero point on the at surface of the bolt in Z to -26.00, i.e. 4 mm

before the end of the bolt. There we set Z to 0, our new zero point for the undercut. So we can

turn the 4mm long undercut exactly to the end of the bolt!

67

Loading...

Loading...