12

The ELS Basic is a control system that sends signals to motors and can thus set the axes of a

lathe in motion. In order for this movement, which is important for lathes, to take place syn-

chronously with the spindle rotation, a feedback signal from the spindle is required. It provides

the decisive signal.

The following components are required for a functional machine:

ENCODER

● An incremental encoder must be mounted on the main spindle.

● An incremental encoder generates pulses that indicate the rotation speed and direction.

The signal must be dierential, the encoder must therefore have connections A, A/, B and

B/ and must be able to operate with 5V. An index signal is not necessary.

● We recommend the type AMT 103-V as it can be mounted on many shaft diameters and the

pulse rate is adjustable.

● Select the pulse rate of the encoder so that [pulse rate] * [spindle speed] is < 1,200,000

Example: Speed=3000 rpm, 400 pulses/rev: 3000x400 = 1.2000.000, which is ne.

● If the pulse rate is too high this can overload the control! The maximum possible speed can

then be reduced.

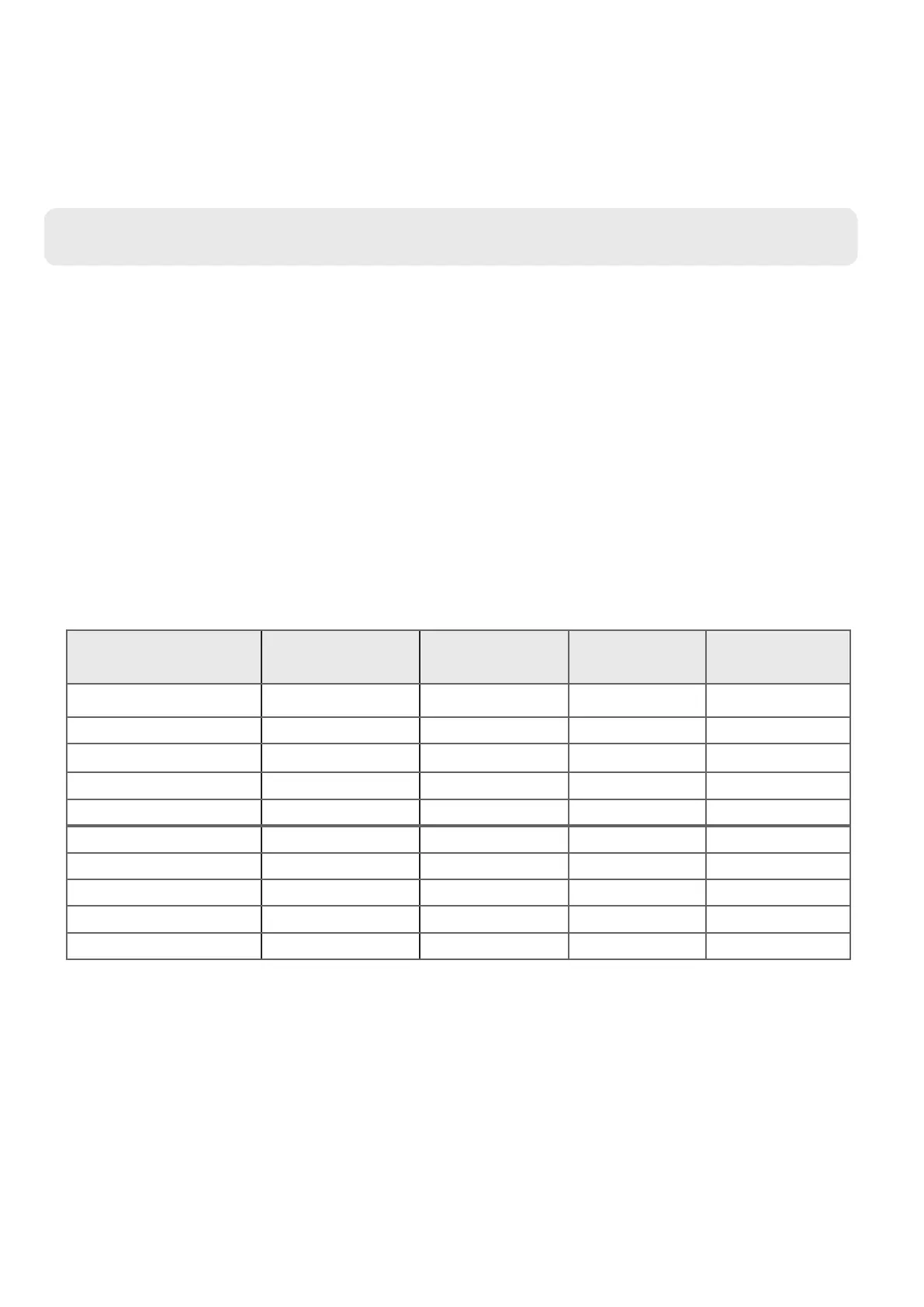

● The following pulse rates are recommended with a ratio [spindle : encoder] of 1:1 and 2:1:

Max. Spindle-

speed

Transmission Impulserate

Encoder

Settings in

ELS

Product

2000 1:1 500 500 1.000.000

3000 1:1 400 400 1.200.000

4000 1:1 250 250 1.000.000

5000 1:1 250 250 1.250.000

6000 1:1 200 200 1.200.000

2000 2:1 250 500 1.000.000

3000 2:1 200 400 1.200.000

4000 2:1 125 250 1.000.000

5000 2:1 125 250 1.250.000

6000 2:1 100 200 1.200.000

● For installation via toothed belt and a transmission ratio deviating from 1:1, the pulse rate

must be selected accordingly (see table above).

● The pulse rate delivered to the ELS per spindle revolution must be entered in the control

settings before starting operation.

● Encoders can be connected directly to terminals or via the Rocketronics „Incremental Line

Driver“ with an Ethernet patch cable (CAT5 or better, S-FTP e.g.) to the RJ45 connector. See

also „Inputs

Loading...

Loading...