EXTERNAL CONE

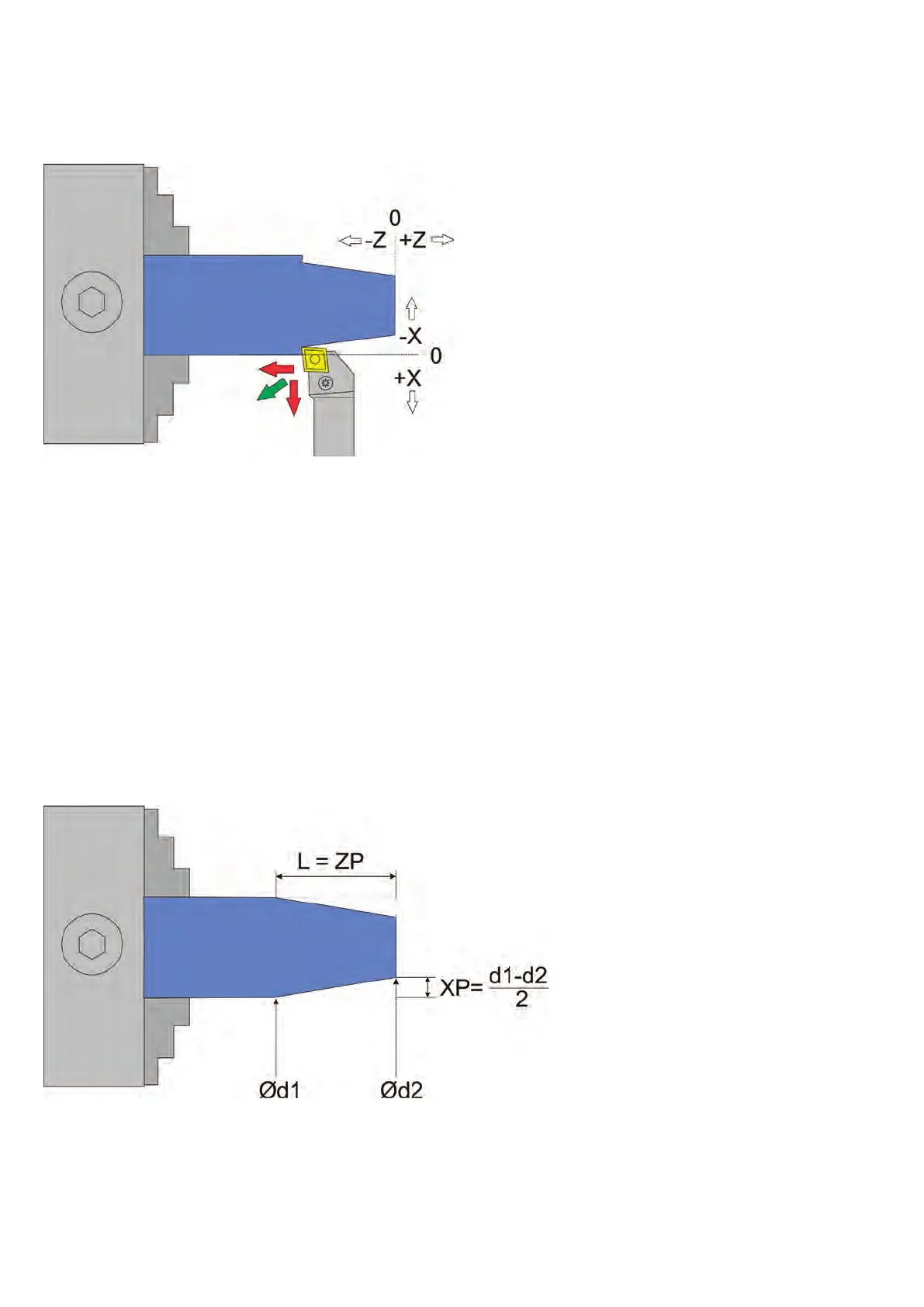

This cycle is used to cut external cones at any angle. The X and Z axes are moved simultane-

ously.

The cuttings of external cones is only possible with a drive on the X axis. The control compen-

sates the radius of the cutting edge of the tool. This goes so far that completely round indexa-

ble inserts can also be used. The radius must be entered correctly in the parameter menu. The

setting is „Tool Corner Radius“.

Due to the Tool Corner Radius compensation, the X axis travels slightly beyond -XP! Even in the

Z direction, a small excess of the ZP path can occur.

An important prerequisite for turning cones is a precisely measured backlash of the X-axis set

in the control system. This can be measured with a dial gauge and must then be entered in the

settings.

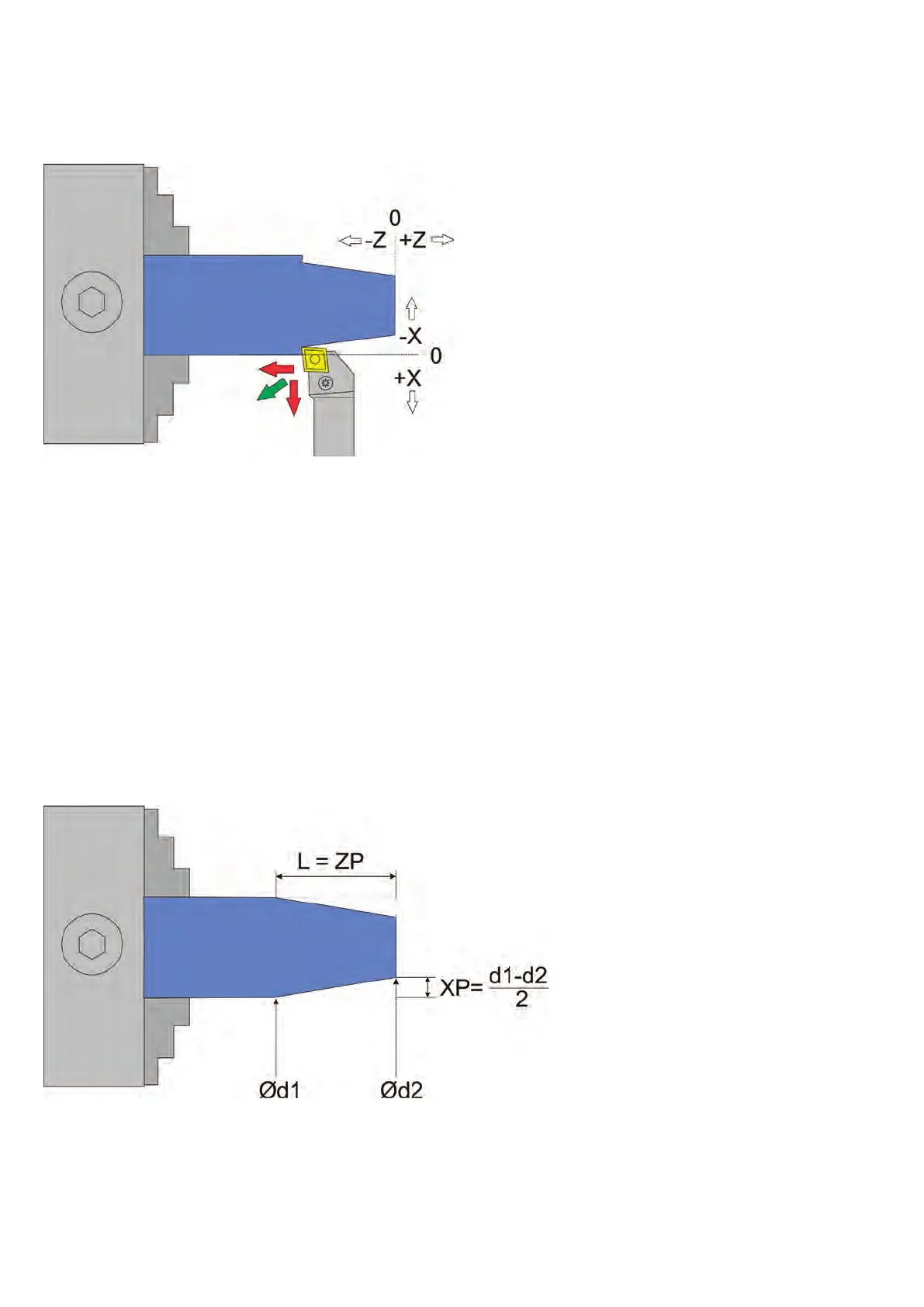

A cone is dened by 2 diameters D1, D2 and the length L:

The controller expects two specications:

ZP – This corresponds to the length of the cone.

XP – The distance in X by which the cone tapers, i.e. (d1-d2)/2

78

Loading...

Loading...