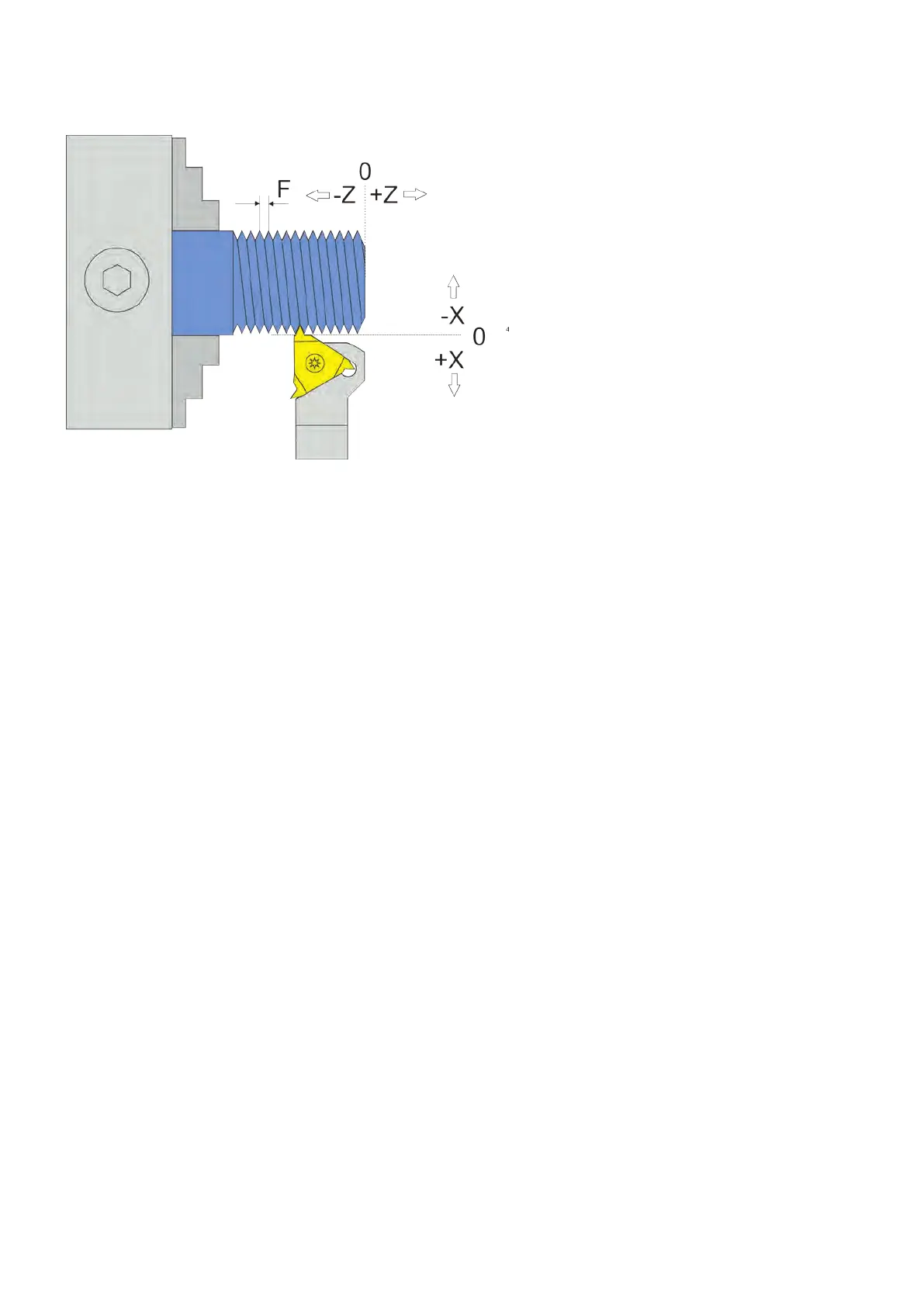

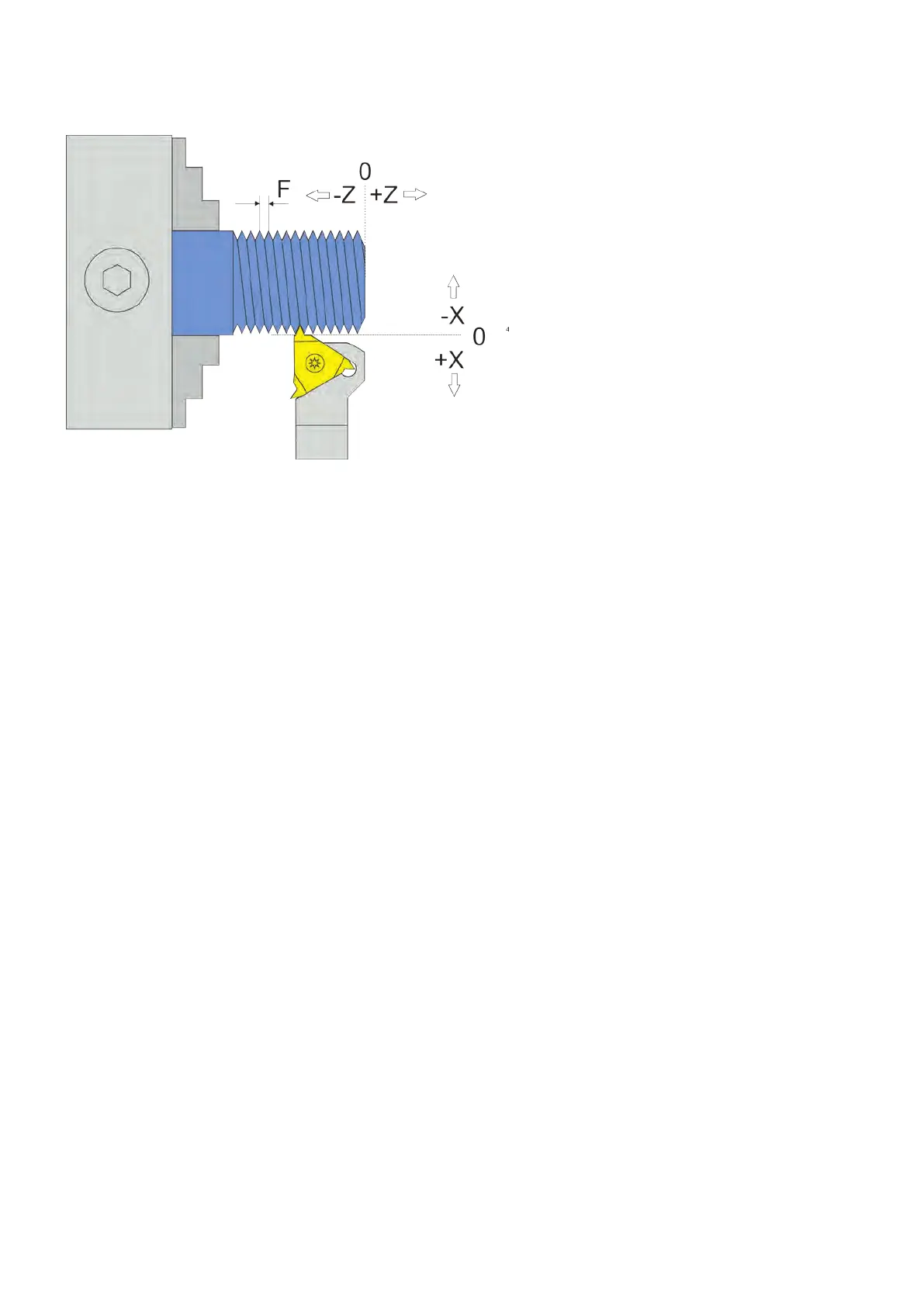

External threads

Starting from the zero point, the lathe tool moves to -X, then to -Z.

ZP = Thread length, XP = the thread depth (ap), F = the thread pitch.

ATTENTION: -X is ALWAYS in the removal direction, in this case -X is so away from the server!

To zero the X axis, always approach the workpiece and set it to 0 to ensure that the backlash is

taken into account.

There are two possible variants:

1. ZP < 0 and XP = 0 so only one length is given, no depth. In this case, the trip after the

START signal goes in -Z direction to ZP without interrogation. The slide stops there until the

WAIT TIME (see Settings) has elapsed and the X axis is retracted manually, and then moves back

to Z, stopping at a point before the zero point. Depending on the speed, this can be several

mm, which it moves beyond 0. The X-axis is not moved but must be moved manually!

2. ZP < 0 XP < 0, so a length and a thread depth are specied. After the START signal, the

controller rst displays all the data for the individual passes in an overview and then starts

again after a new start command. Here you can also abort at any time by pressing the STOP

buttons. The return travel always takes place in X slightly above the zero point, because other-

wise the cut thread would break. It also moves beyond 0 in the +Z direction.

This mode is suitable for turning threads from the zero point, but in this case the thread is

moved beyond 0 because of the required starting distance, which in some cases prevents the

use of the tailstock. If you are unsure, it is advisable to do a test run at the desired speed, leav-

ing XP at 0 so that no infeed is made.

If you want to run without any starting distance, the mode „THREAD <0“ must be selected, this

mode does not last beyond 0, but you have to make sure to keep it far enough.

71

Loading...

Loading...