Re-Cut thread at full depth

If the thread does not quite t after the cut, you can start a new pass and simply turn the

number of passes to 1, then another pass is made at maximum deptch, often this is enough to

remove the missing last hundredths and make the thread t. Some material is not suitable for

turning and has to be turned several times to full depth until it ts. This is where trial and error

helps.

LEFT THREADS

This is not a separate mode, but there are several ways to turn a left-hand thread:

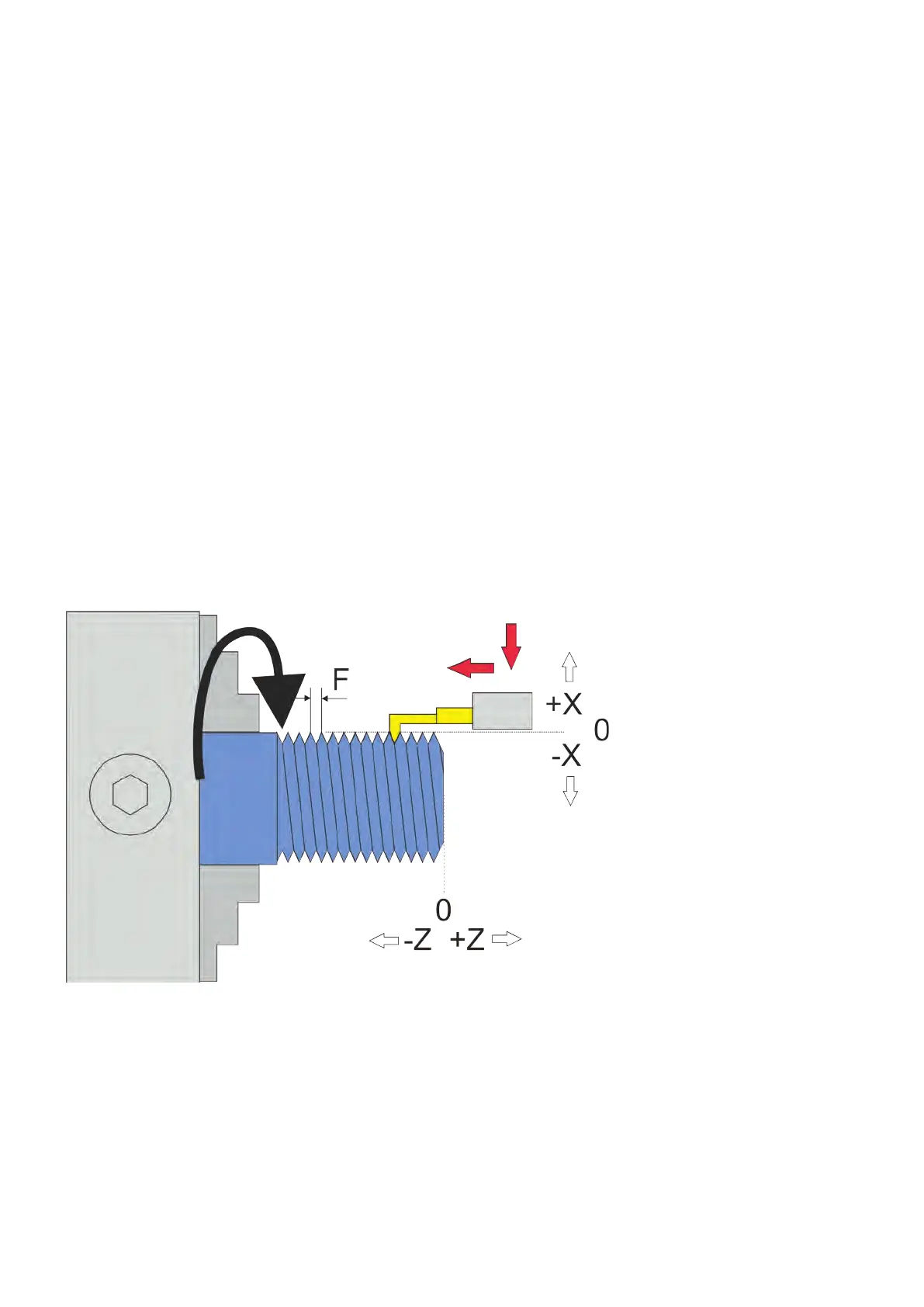

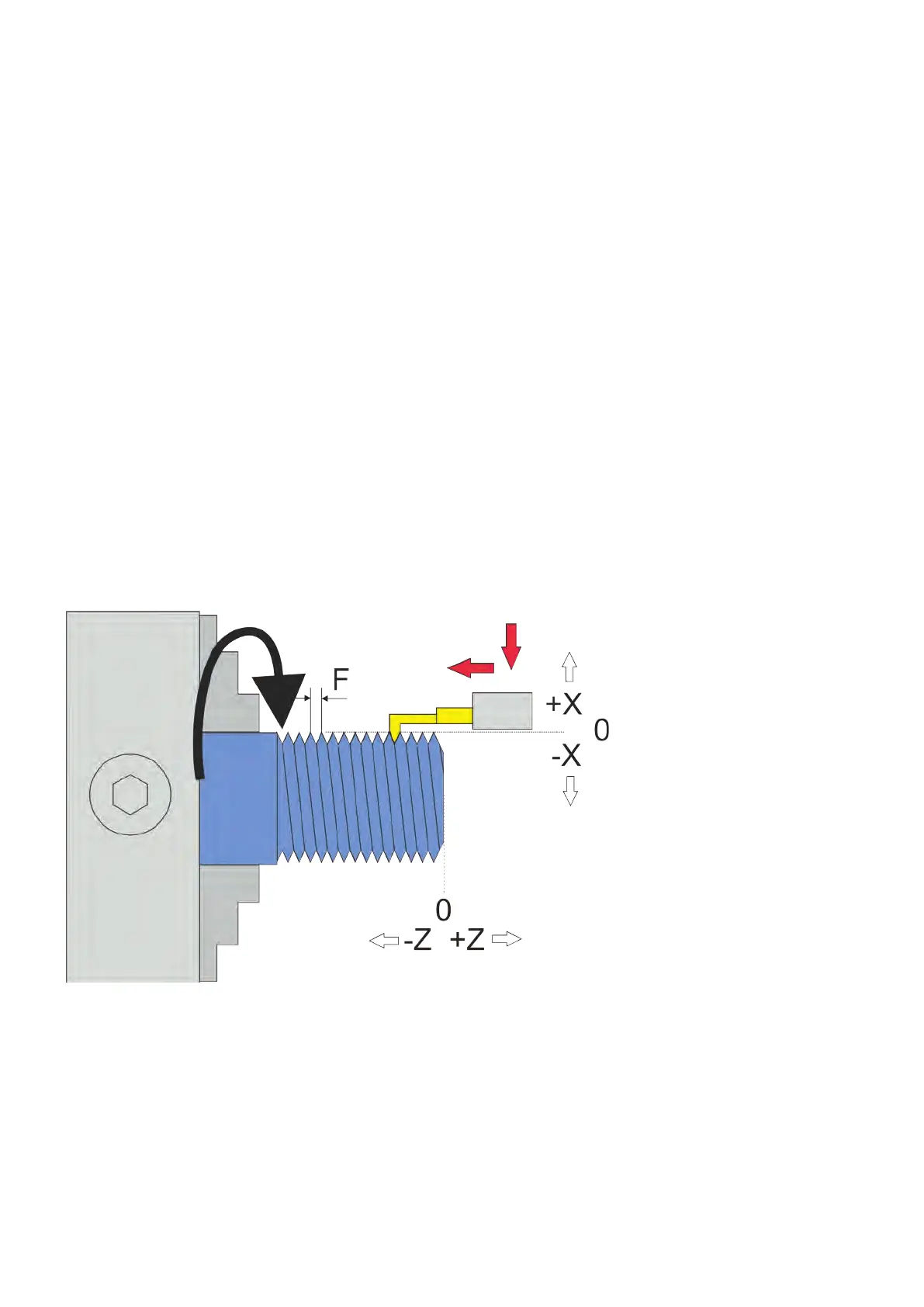

1. Turn the turning steel around and let the spindle turn clockwise. Then you can turn the

external left-hand thread in the external thread mode.

2. Use an internal thread turning tool and place the opposite end of the workpiece. Then

you use the internal thread mode(!) to turn an external left-hand thread when the spindle is

turning clockwise. In internal thread mode, the thread is fed to the operator, which in this case

produces an external thread. Somewhat tricky, but easy to do. The zero point in X must then of

course be set moving towards the operator, as is usual in internal modes.

75

Loading...

Loading...