Rockwell Automation Publication KNX-SG001H-EN-P - December 2020 29

Product Features Comparison

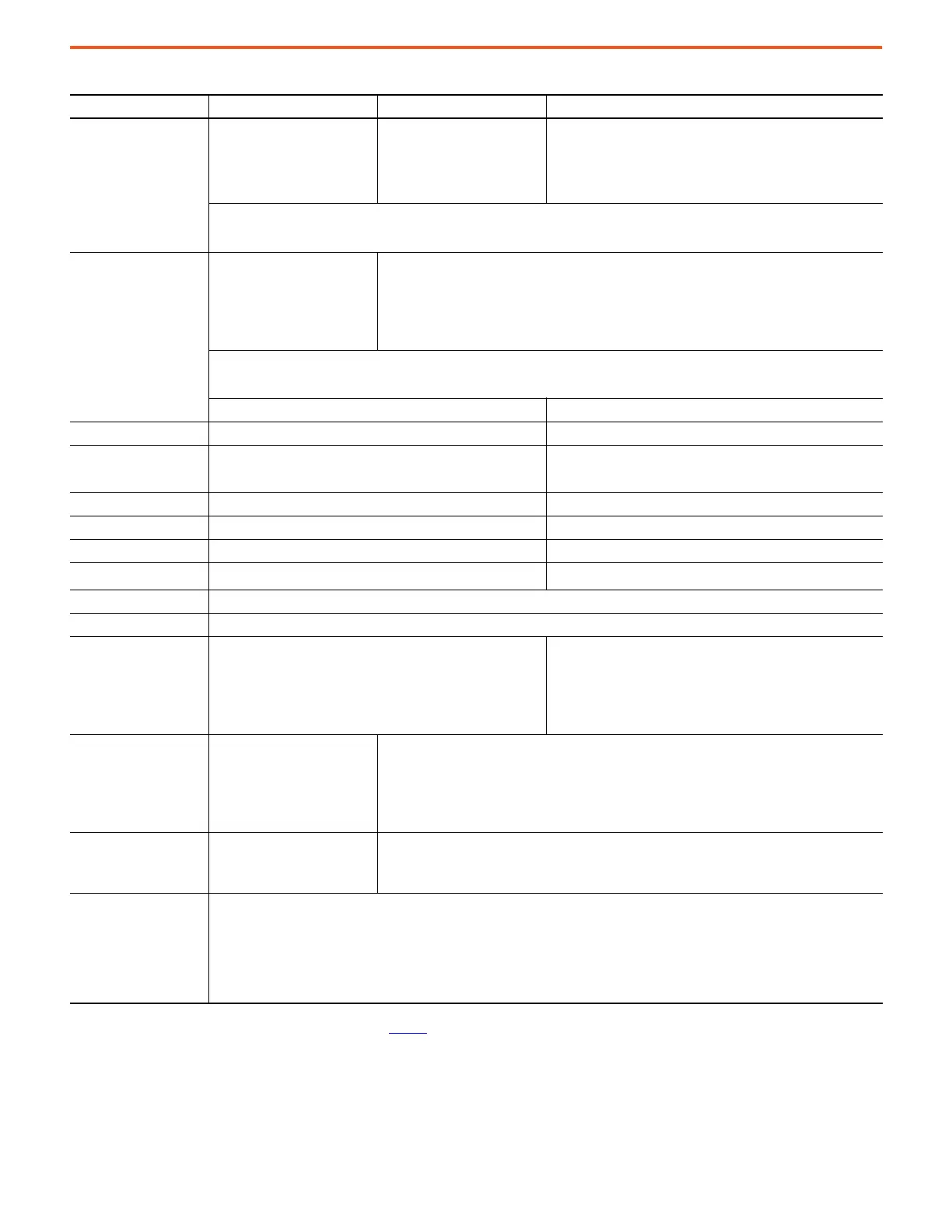

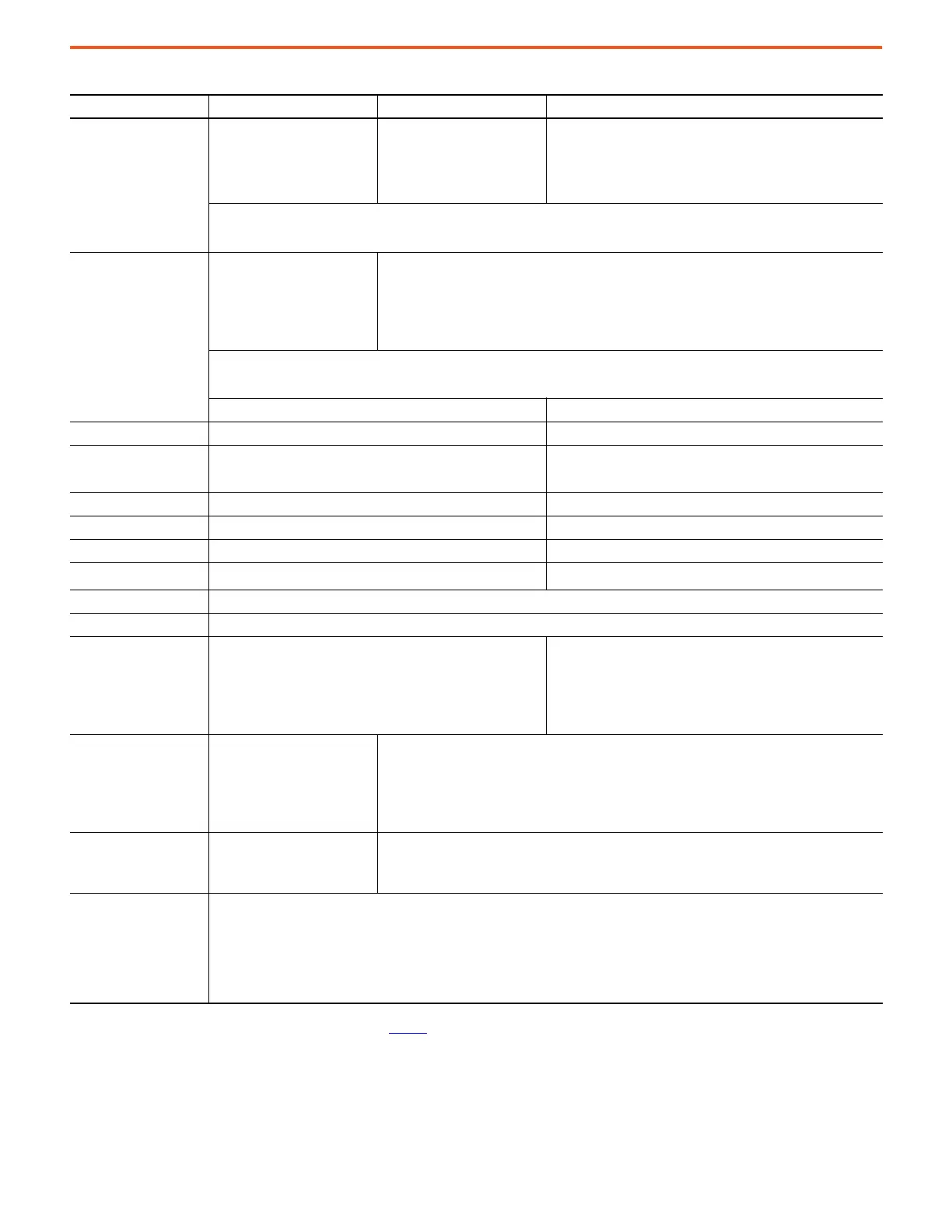

Kinetix VP and Kinetix MP Electric Cylinders

Actuator Features Kinetix VPAR Electric Cylinders Kinetix MPAR Electric Cylinders Kinetix MPAI Heavy-duty Electric Cylinders

Main characteristics

State-of-the-art design features

ballscrew construction driven by

Kinetix VPL servo motors

State-of-the-art design features

ballscrew construction driven by

Kinetix MPL servo motors

• State-of-the-art design features ballscrew and roller screw construction

driven by Kinetix MPL servo motors

• Front flange-mount, front trunnion-mount, and rear clevis-mount

cylinders

• Food-grade (paint) option with epoxy coating and corrosion resistant

stainless steel fasteners and accessories

• Fully assembled and ready to mount cylinders contribute to reductions in mechanical design engineering, wiring, and commissioning time

• Smart Motor Technology

• Very high linear speeds

Features

• 200/230V and 400/460V

operation

• Absolute, high-resolution

feedback options consistent with

Kinetix VPL servo motors

• 2090-Series single-cable

technology

• 200/230V and 400/460V operation

• Absolute, high-resolution feedback options consistent with Kinetix MP servo motors

• Standard Kinetix MP motor power and feedback connectors

• Rated for 100% duty cycle and designed for repeatable, reproducible performance over the actuator's operating life

• Absolute feedback allows operation without limit and home switches

• No piping, valving, air, or oil supply required

ISO 15552 pneumatic-class frame sizes 32, 40, and 63 mm Frame sizes 64, 83, 110, and 144 mm

Actuator type Ball-screw driven electric cylinders Ball-screw and roller-screw electric cylinders

Environmental rating

• IP40 (complete unit) includes rod-end seal and breather port

• IP66 applies to electronic components with the use of Rockwell

Automation factory-delivered 2090-Series cable connectors

IP66/IP67 (in static condition only) and with the use of Rockwell Automation

factory-delivered 2090-Series cable connectors

Continuous stall force 240…2000 N (54…450 lb) 706…13,122 N (159…2950 lb)

Max feed force 300…2500 N (67…562 lb) 1446…14,679 N (325…3300 lb)

Peak velocities 150…1000 mm/s (5.9…39.4 in/s) 176…610 mm/s (6.9…24.0 in/s)

Stroke lengths

(1)

(1) Not all stroke lengths (travels) are available with all frame sizes.

100…800 mm (4.0…32.0 in.) 076, 150, 300, 450 mm (3.0, 6.0, 12.0, 18.0 in.)

Feedback options Multi-turn, high-resolution absolute position

Optional equipment 24V DC holding brakes

Field-installable accessories

• Foot mounting

• Flange mounting

• Trunnion mounting kit

• Trunnion support

• Mounting attachments (swivel flange, trunnion)

• Piston-rod attachments (rod eye, rod clevis, rod coupler)

•Guide rod

• Mounting plates

• Front flange mount

• Rear clevis mount

• Rod-end attachments (rod eye, rod clevis)

• Anti-rotation option

Compatible drives

(2)

(2) For Kinetix 2000 drive specifications, refer to Additional Resources on page 233 for links to the applicable technical data and design guide publications.

•Kinetix 5700

•Kinetix 5500

•Kinetix 5700

•Kinetix 5500

•Kinetix 5300

• Kinetix 6200/6500

•Kinetix 6000

• Kinetix 300/350

•Kinetix 2000

Servo cable compatibility

• 2090-CSxM1xx-xxAA/AFxx

(TPE) cables

• 2090-CSxM1xx-xxVA/LFxx

(PVC and PUR) cables

2090-CxxM7xx cables

Typical applications

• Material handling (loading, unloading, lifts, pick and place, diverters, transfers, gantries)

• Volumetric filling and process control (web guides, valve, nozzle, van, and gate positioning)

• Fabrication (adjustments for machine backstops and cutting tools, works alignment)

• Push, pull, eject, press, or clamp parts

• Packaging (consumer products, automotive, medical)

• Electronic assembly

•Insertion systems

• Inspection and test equipment

Loading...

Loading...