Open Receiving Hopper

The aggregate is emptied into the receiving hopper

using a typical dump truck. Before the dump truck

backs up to the receiving hopper, lower the hopper

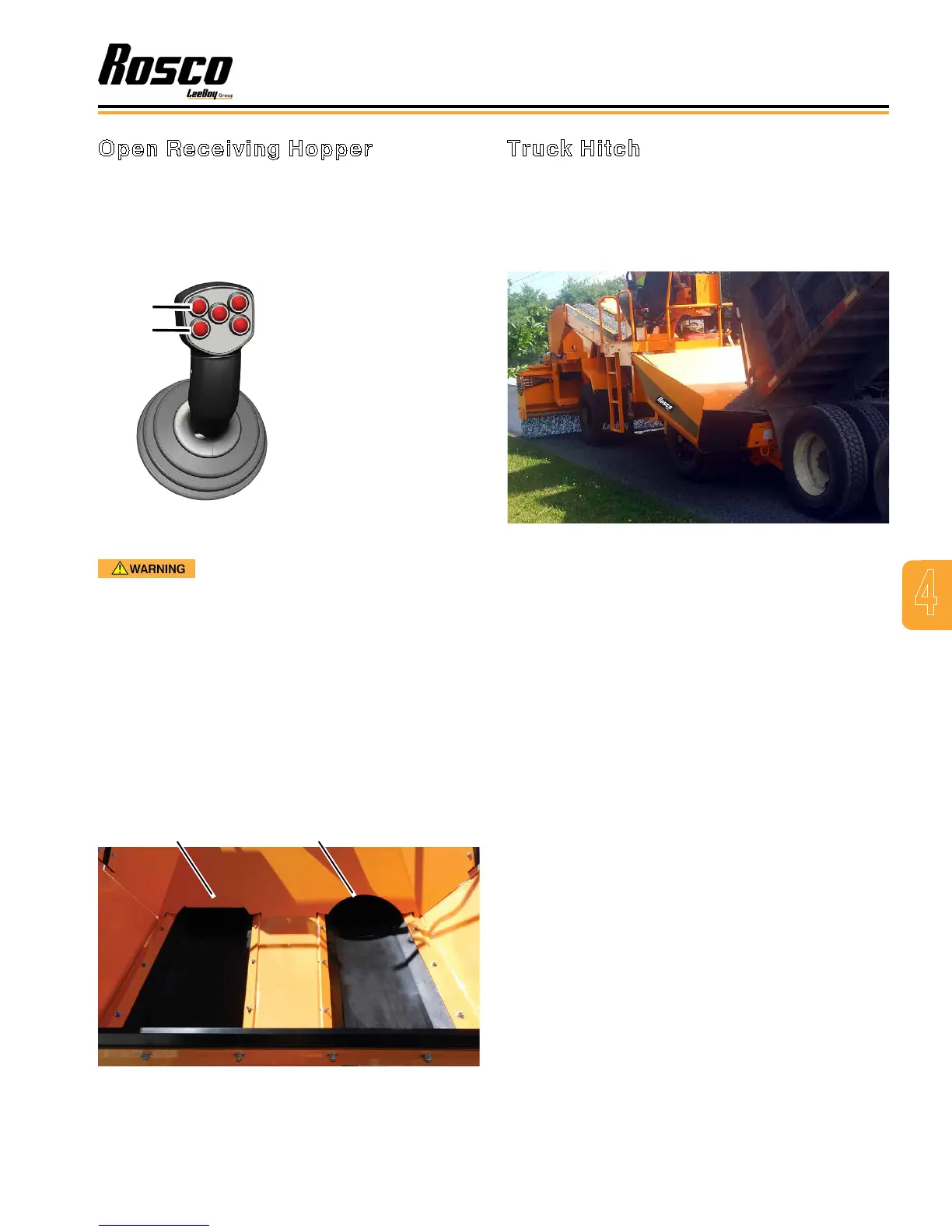

wings (opens hopper) by pressing the bottom left button

(Down) on the joystick. (Figure 4-26)

Up

Down

Figure 4-26. Hopper

Wings Control

NOTE: DO NOT open or

close the hopper

wings while the

dump truck is in

close proximity

or hitched to the

receiving hopper.

The receiving hopper width is 10 feet

when fully extended. Use extreme caution to prevent

damage or serious injury from trafc and roadside

obstacles while chip spreading.

The operator (or a ground helper) will also need to

open or close one or both of the feed gates in the

receiving hopper. (Figure 4-27) The feed gates

regulate aggregate ow on the conveyors to the spread

hopper. If using only one conveyor, close the other feed

gate completely. If you notice excessive spillage or

overowing at the spread hopper, lower the feed gates

accordingly.

Closed

Feed Gate

Open

Feed Gate

Figure 4-27. Receiving Hopper Feed Gates

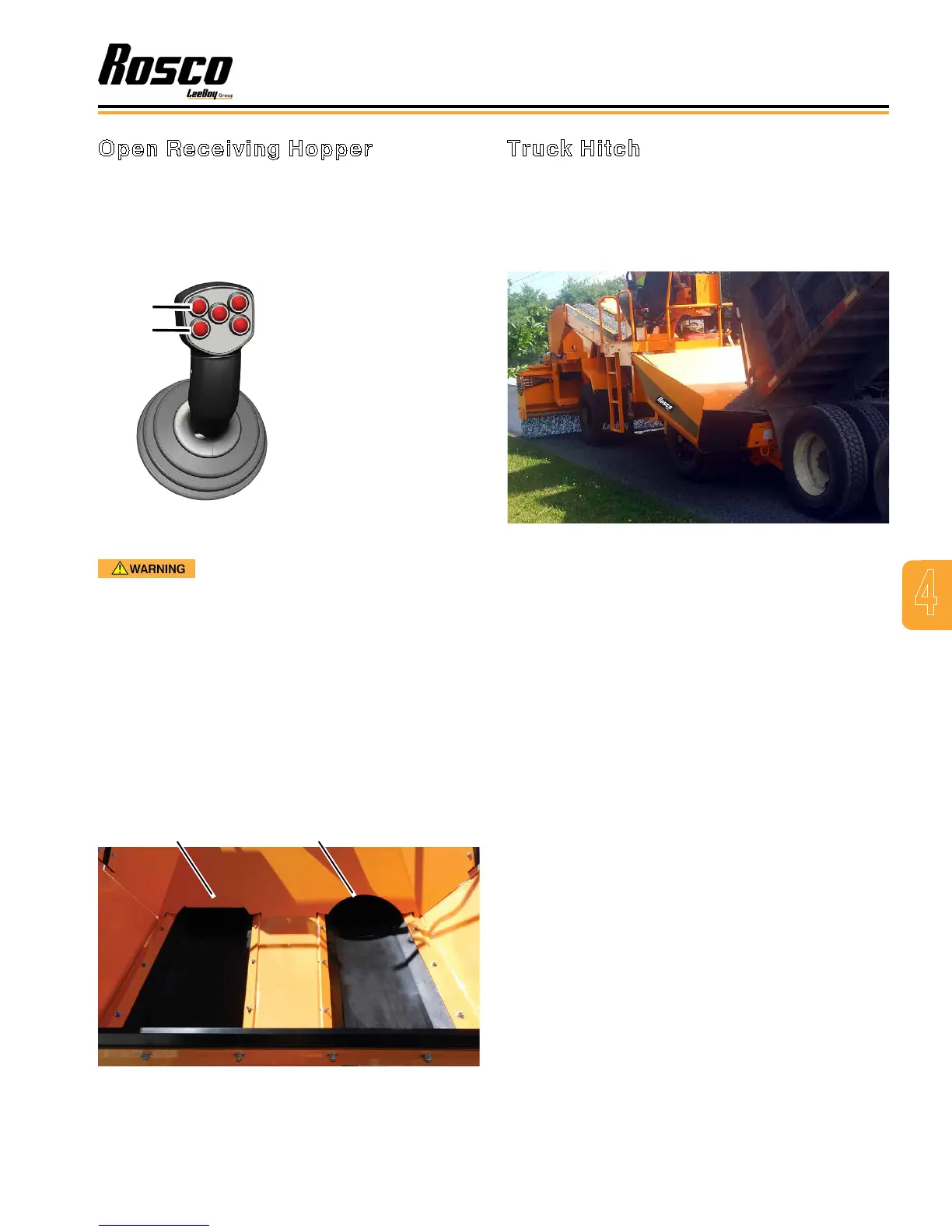

Truck Hitch

The success of the entire spreading function is directly

related to the dump truck hook-up to the receiving

hopper, and care should be taken to ensure accuracy.

The truck hitch provides the means for the truck to be

held in close proximity to the receiving hopper.

Figure 4-28. Dump Truck Hitched to Receiving

Hopper

The dump truck must be compatible to prevent any

interruption of aggregate supply. In general, the

tailgate of the truck bed should be set eight (8) inches

(203.2 mm) inside the retaining rubber skirt of the

receiving hopper when the bed is raised. Frame length,

the overhang of the dump truck bed frame, and the

relationship of the rear wheels to the frame vary among

trucks. Therefore, a thorough check of each truck bed

in relation to the receiving hopper must be made prior to

starting to spread.

Single-axle trucks carry 5 - 7 tons (4500 - 6350 kg)

while tandem-axle trucks carry 11 - 14 tons (9000 -

12,700 kg). Tandem-axle haul trucks are recommended

as the increased capacity requires fewer hook-ups, less

chance of spillage, and more efcient operation. On

large, tandem-axle trucks, the frame, rear wheels and

gate of the dump bed may be on the same vertical line.

Extensions to the truck bed may be necessary to ensure

a proper seal when attaching to the dump truck. Hitches

should be installed to allow a minimum of two inches

(50.8 mm) clearance between the rear truck tire and the

bumper of the chip spreader.

NOTE: Dump trucks should be in good mechanical

condition. Leaking dump trucks can

compromise the seal binder.

4

Operation

Rosco CSV Variable Width Chip Spreader 4-19

Loading...

Loading...