Trucks should drive VERY SLOWLY on the new surface

and never brake sharply to prevent wheel spin and

mat damage. Do not allow trucks to dump chips when

pulling away from the chip spreader, make sharp

turns or drive too fast on a newly-constructed chip

seal. When driving on the fresh mat, the truck wheel

paths should be staggered to assist in embedding the

aggregate uniformly.

Check the aggregate level in the

receiving hopper regularly while chip spreading.

Signal the truck driver to reload as needed.

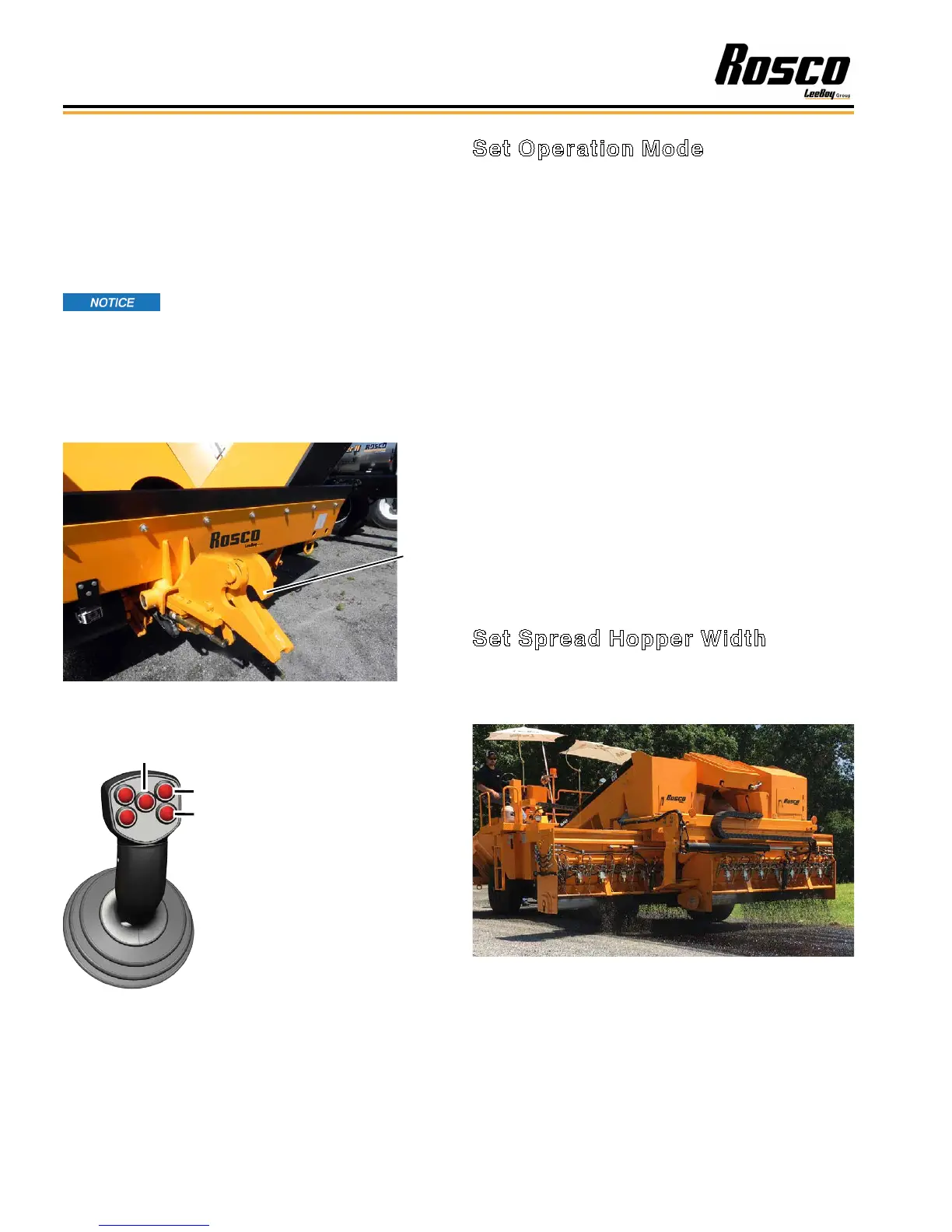

The CSV Variable Width Chip Spreader is equipped with

a positive-latching, hydraulic-release truck hitch that

secures the chip spreader to the pull bar on the dump

truck. (Figure 4-29)

Latch

Figure 4-29. Truck Hitch

Up

Down

Figure 4-30. Truck Hitch

Controls

The truck hitch controls

are located on the joystick

(Page 3-10). Pushing the

top right button raises the

truck hitch while pushing

the lower right button

lowers the hitch. The hitch

will automatically lock into

position.

The center button

releases the truck hitch.

(Figure 4-30)

Set Operation Mode

The operation mode switch defaults to Manual upon

start-up. In the Manual mode, the operator manually

controls the spread hopper gate openings and

conveyor speed on both sides from the control console.

When you select the Auto mode on the control console

(Page 4-5), the onboard computer will control the

spread hopper gate openings once the desired PSY,

rock size and type, and spreading FPMs has been

entered into the DP710 digital display.

Speed control is always active in the forward direction

while operating in the Auto mode. The control system

will automatically reach and maintain the desired ground

speed. If you move the joystick back toward center, the

machine will slow down proportionately until the joystick

is centered. (Moving the joystick into reverse closes the

spread hopper gates and shuts off the automatic ground

speed control.)

If operating in the Auto mode, the control system will

automatically resume the set operation. You will need

to back up (about four car lengths), then propel forward

for the automatic resume feature to activate.

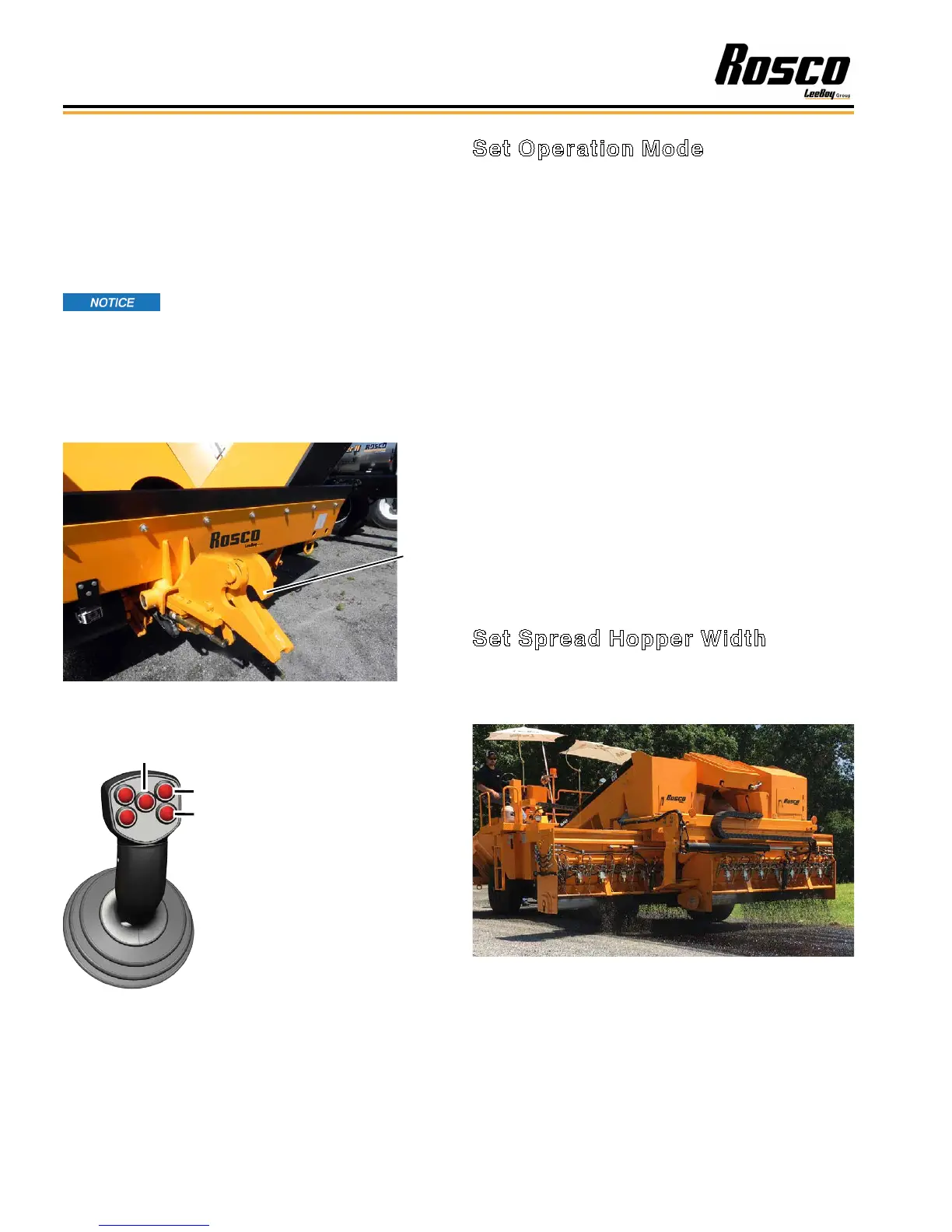

Set Spread Hopper Width

The front spread hopper is eight feet wide, with a

hydraulic extension on each side that can extend four

feet each for a total width of 16 feet. (Figure 4-31)

Figure 4-31. Right Spread Hopper Extended

1. Measure the width of the surface to be paved.

2. Extend either the left, right, or both extensions to

achieve the coverage needed using the spread

hopper extension buttons on the control panel.

(Figure 4-32)

Operation

Rosco CSV Variable Width Chip Spreader4-20

Loading...

Loading...