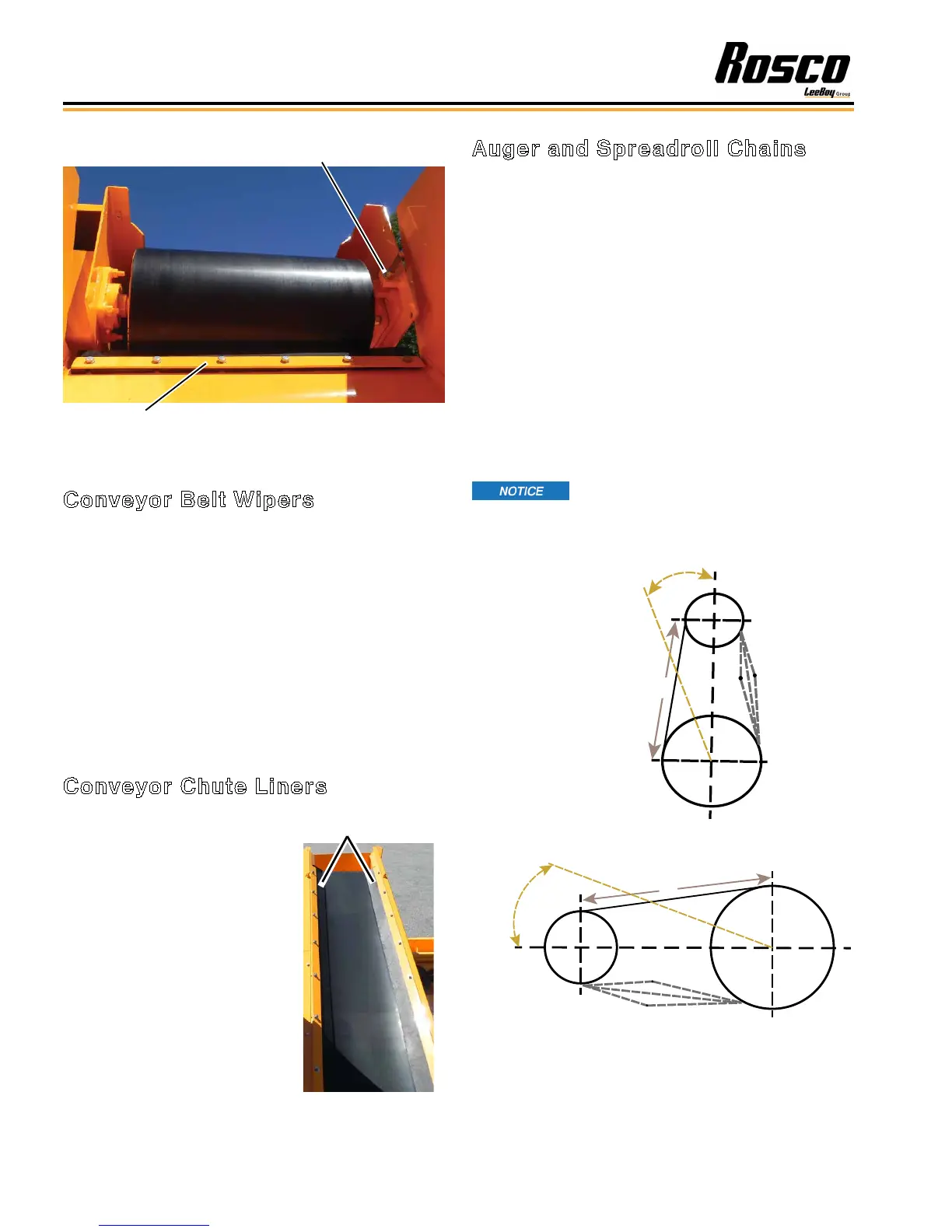

Head Pulley Adjuster

Belt Wiper

Figure 5-7. Head Pulley Adjuster and Belt Wiper

Conveyor Belt Wipers

The conveyor belt wipers are mounted immediately

below the conveyor head pulleys and contact the

conveyor belt. (Figure 5-7) They serve to remove

any material sticking to the belt as it moves toward the

receiving hopper. Periodically check for clearance

between the conveyor belt wipers and the conveyor

belts. You can access the belt wiper(s) via the front

conveyor panels.

To adjust the conveyor belt wipers, loosen the bolts

across the channel strip and move the wiper up until it

touches the conveyor belt.

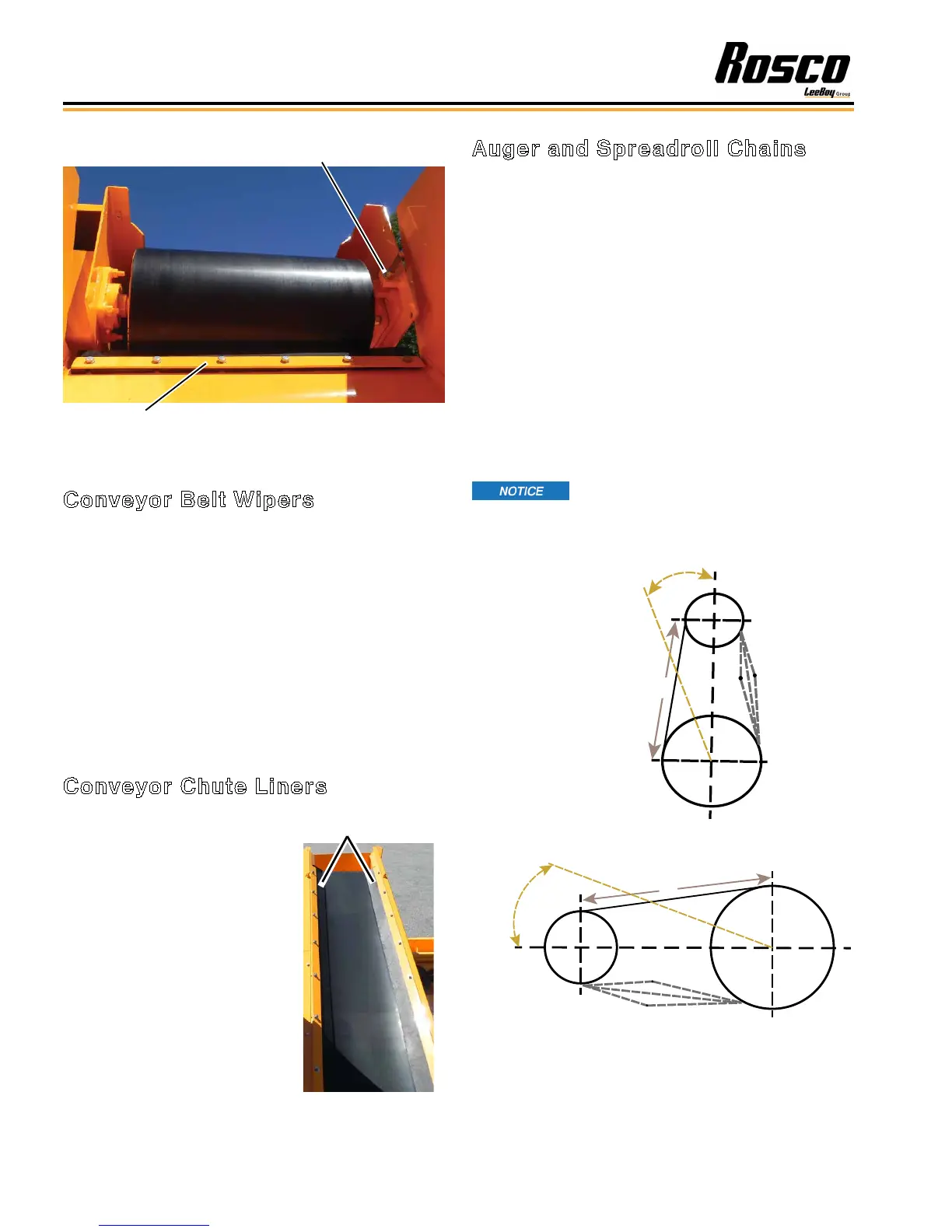

Conveyor Chute Liners

Rubber chute liners are located

on each side of the conveyor

belts to prevent aggregate

material from leaving the

conveyors. (Figure 5-8) They

should also be periodically

adjusted to touch the conveyor

belts evenly along the entire

length of the conveyor belts.

Adjust the chute liners when

necessary by loosening the

channel strip bolts and moving

the rubber liner until it touches

the conveyor belt.

Chute Liners

Figure 5-8. Chute

Liners

Auger and Spreadroll Chains

The auger and spreadroll hopper chains need periodic

adjustment, and should be inspected every 50 hours of

operation.

Generally, the slack of a roller chain should be on the

lower side. (Figure 5-9 and Table 5-3) Adequate

slack (S) is about four (4) percent of the span for normal

drives, but the slack should be about two (2) percent of

the span for the auger chains:

• Vertical drive or close to vertical drive.

• Center distance between two shafts is greater than

three (3) feet.

• Chain is operated under heavy load and high

frequency of on and off drive.

• Direction of the drive is often changed.

Auger and conveyor chains must have

a slack of 1/4 to 3/8 inches. To measure deection,

exert 40 - 60 pounds of force to chain in either

direction.

TL

45º

Horizontal to 45° Chain Tension

45° to Vertical

Chain Tension

S

S

45º

TL

S - SLACK

TL - TANGENT LENGTH

Figure 5-9. Chain Slack Adjustment for Proper

Tension

Maintenance

Rosco CSV Variable Width Chip Spreader5-10

Loading...

Loading...