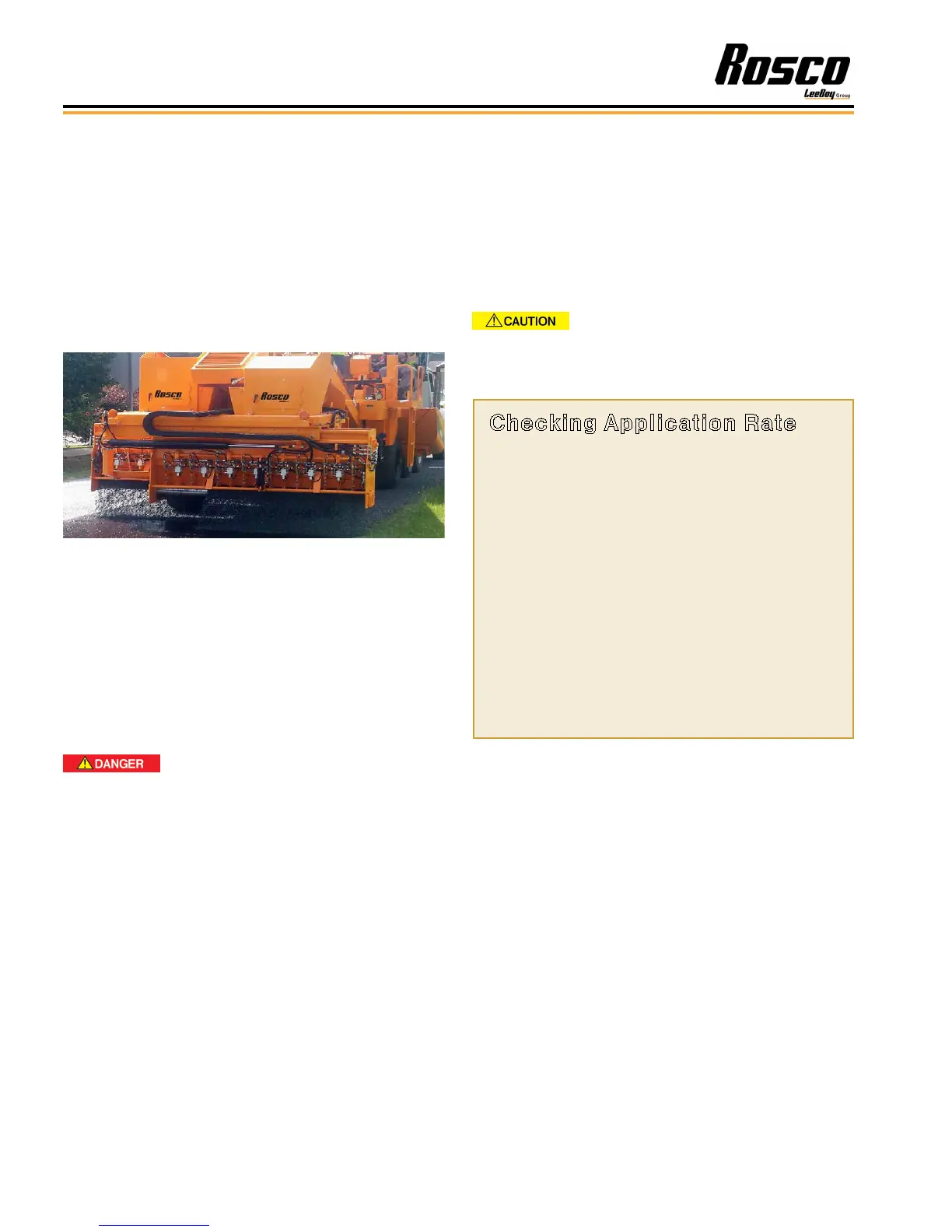

CHIP SPREADING OPERATION

The CSV Variable Width Chip Spreader is propelled

by a hydrostatic transmission with a single two-speed

motor driving the axle. Aggregate is emptied into the

receiving hopper from a typical dump truck and moved

via two conveyors to the spread hopper in the front

where individual gates are hydraulically opened. Within

the spread hopper, a spread roll rotates to provide

consistent, uniform aggregate application to the binding

material sprayed onto the paving surface. (Figure 4-25)

Figure 4-25. Chip Spreading

It is important that operators understand system

functions and controls before operating the machine for

successful results. Pay attention to the DP710 digital

display as the main screen shows the status of various

functions set on the control console. (Page 4-9)

Be sure trafc control operations are in place before

beginning the chip spreading project. As soon as the

chip spreader is in place, line up the asphalt distributor

truck in front.

Always sound the horn before moving

the chip spreader and ensure no people are in its

path. Serious injury or even death can result.

In order for the chip spreader to propel from a stationary

position, remember:

• The park brake must be disengaged.

• The joystick(s) must be in the neutral position.

• The desired operator control console must be

activated (if equipped with dual operator stations).

• You must step on the service brake and release, then

propel forward or reverse using the joystick. (If you

try to propel without stepping on the service brake, an

error code will ash on the DP 710 digital display.)

• If the machine sits idle more than 10 seconds, the

joystick will time out and you must step on the service

brake again.

NOTE: Extend both spread hopper extensions,

navigate to the Settings screen on the

DP710 digital display and perform a “hopper

dump” before lling the receiving hopper,

especially if the machine has not been used

for awhile. This clears any debris or old

aggregate from the hoppers. This is a good

habit if there are multiple operators or a

variety of aggregate used.

Avoid low limbs, power lines and other

objects that can endanger crew or chip spreader.

Checking Application Rate

Checking the aggregate application rate can be

accomplished using the following recommended

method. This method is also used for PSY

calibration:

1. Enter your target PSY rate into the DP710

digital controller. (Page 4-14)

2. Place a tarp measuring one square yard (.84

m

2

) onto the roadway and apply aggregate

onto it.

3. Weigh the tarp with the aggregate. This is your

actual PSY rate.

4. Enter the actual PSY rate into the DP710 digital

controller.

Operation

Rosco CSV Variable Width Chip Spreader4-18

Loading...

Loading...