REPLACEMENT PROCEDURES

Replace Batteries

Batteries create explosive gases

when charging. DO NOT expose these gases to

sparks or open ame during maintenance. Always

perform battery service in a well-ventilated area or

outside. Serious injury can occur from exploding

batteries.

When installing batteries, always

install the positive cable rst followed by the

negative cable. Reversed polarity can damage the

electrical system.

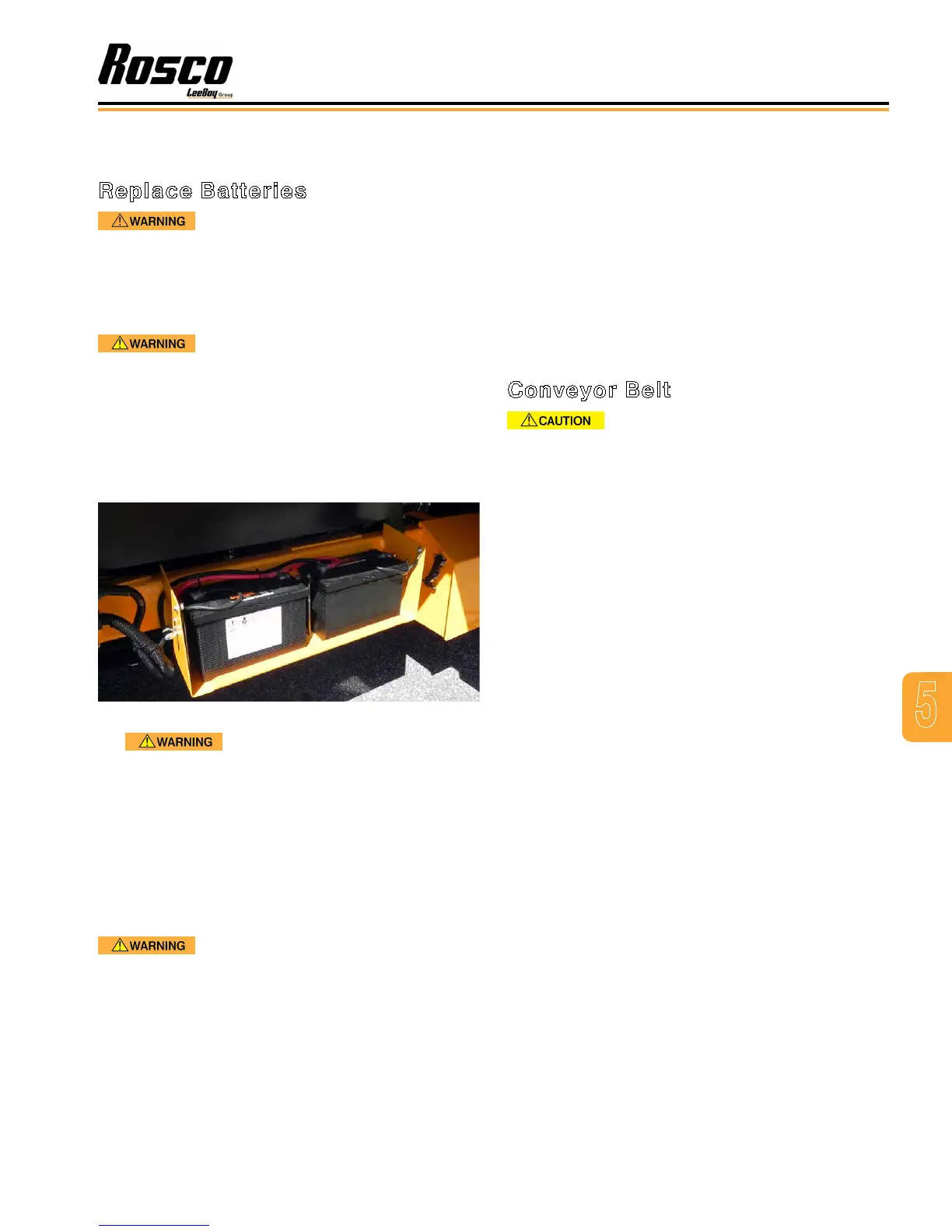

1. Remove the black ground (-) cable from the

negative (-) battery terminal, followed by the red (+)

cable from the positive (+) battery terminal. (Figure

5-32)

Figure 5-32. 12-Volt Battery System

If the negative cable is grounded

during removal, sparks will not occur. If the positive

cable is grounded during removal, sparks will occur

and could ignite explosive gases.

2. Remove the hold down bar.

3. Inspect the batteries for cracks, wear and damage

that could result in leaks.

4. Carefully remove the batteries from the battery

plate, noting battery position during removal.

DO NOT dry batteries using

compressed air. Allow the batteries and surrounding

area to dry. Battery acid can cause severe injury if

blown into the face or other areas of the body. If injury

occurs, seek medical attention immediately. Flush

eyes and skin for 30 minutes with clean water.

5. Make sure the battery cells are sealed. Clean the

batteries, battery tray, cables, and brackets with

baking soda and warm water. Allow to air dry.

6. Place the batteries in proper position in the battery tray.

7. Install hold down bar. Tighten bar to retain battery,

but not so tight as to damage battery.

8. Install red (+) battery cable to the positive (+) battery

terminal.

9. Install the black (-) battery cable to the negative (-)

battery terminal.

10. Reattach the battery box cover and reconnect the

battery box locks.

Conveyor Belt

The conveyor belt weighs nearly

400 pounds. It will require more than one person to

replace the belt.

NOTE: When installing a belt, use the old belt to

pull the new belt onto the machine.

For conveyor belt replacement, refer to Page 5-8 and

proceed as follows:

1. Move the existing belt so that the belt joint is on the

top surface near the conveyor head pulley bearing.

2. Remove the belt lacing pin to disengage the belt.

3. Attach one end of the new belt to the top of the old

belt. Attach the belts together with the lacing pin.

4. Slowly thread the new belt around the pulleys back

to the tail pulley group while removing the old belt

from the conveyor.

5. Stop the machine when the end of the new belt is on

top of the pulley group.

6. Remove lacing pin and move old belt clear of the

area.

7. Secure the two ends of the new belt together with

lacing pin.

8. Check that the new belt is properly adjusted and

centered.

5

Maintenance

Rosco CSV Variable Width Chip Spreader 5-25

Loading...

Loading...