DEF Tank Filter

The DEF tank lter should be cleaned or replaced every

2000 hours, or every two years, whichever is rst. The

lter is the rst point of contact with foreign elements.

To clean or replace the DEF tank lter, remove the DEF

header tank assembly using the following procedures.

The DEF lines are connected using quick-release

ttings and must be disconnected in the order

described below. (Figure 5-18)

NOTE: It is imperative that you disconnect the

plumbing from the header in the exact order

described below to prevent accidental DEF

contamination of the electrical connector.

Wear eye protection, gloves and

appropriate protective clothing to avoid injury. The

coolant lines connect to the after treatment dosing

unit are hot and under pressure. DO NOT disconnect

while the engine is running or before the system has

purged and cooled down after shutting down the

engine. Disconnecting the coolant lines before the

system cools down may cause coolant to spray and

burn skin on contact.

1. Complete Steps 1 - 4 to prepare machine for DEF

system maintenance.

2. Place a container under the DEF tank as a small

amount of DEF may drain from the coolant lines

when disconnected. (Dispose of the uid in

accordance with environmental regulations.) DO

NOT ush the coolant.

3. Use a clean, damp cloth to wipe the unit to reduce

the risk of contamination entering the DEF tank.

Wipe away any spilled DEF while servicing the DEF

tank lter.

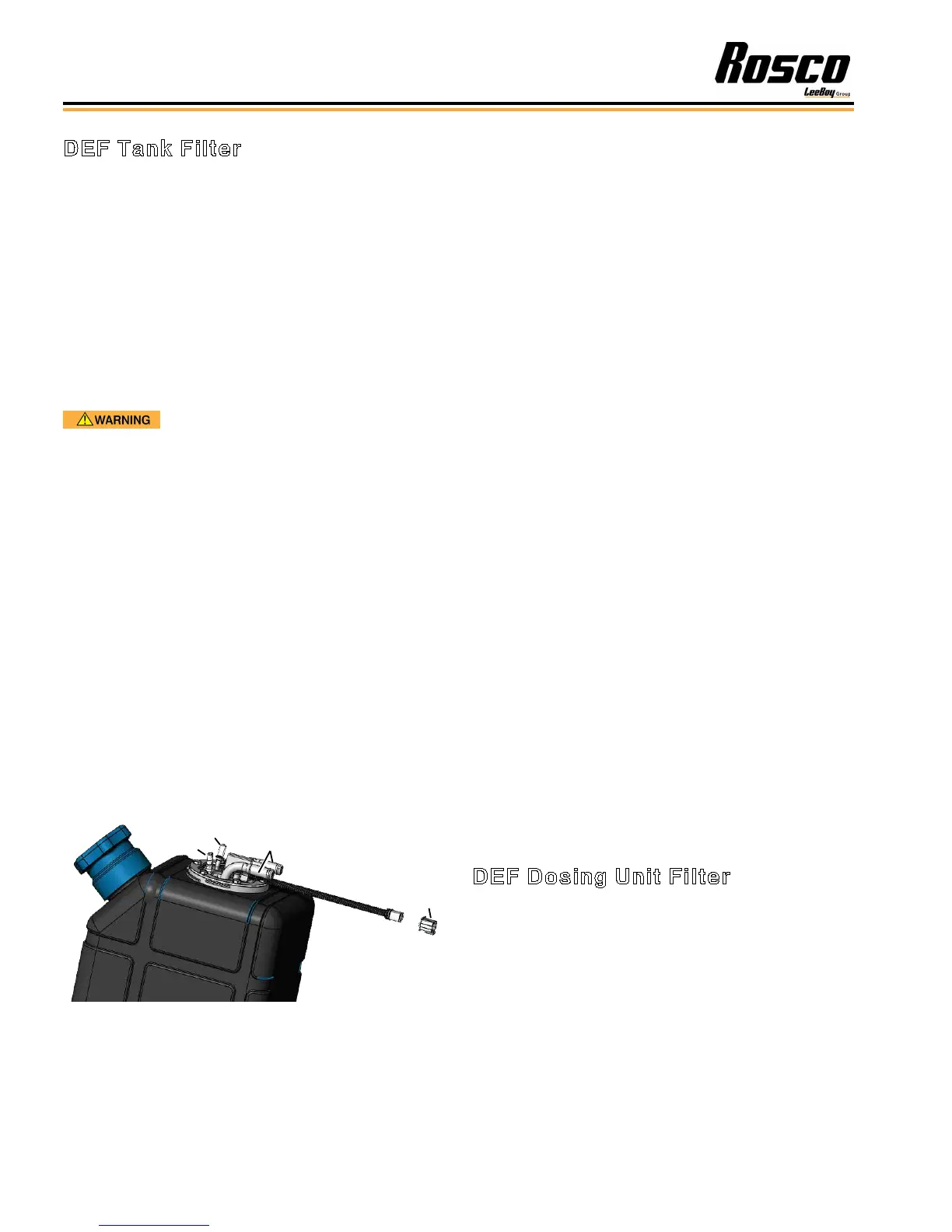

1

2

3

4

Figure 5-18. DEF Tank Header Assembly

1 - Suction DEF Connector

2 - DEF Connector

3 - Coolant Connectors

4 - Electrical Connector

4. Disconnect the coolant connectors and cap the

lines to prevent contamination or DEF leakage.

Figure 5-18) (You can also use a pair of coolant

hose pinch-off pliers to clamp the lines. Make sure

the tank coolant hose material is exible enough.)

DO NOT drain the cooling system. DO NOT spill any

coolant into the DEF tank.

5. Disconnect the DEF connector.

6. Disconnect the suction DEF connector.

7. Disconnect the back-ow DEF connector.

8. Disconnect the electrical connector by pressing the

top of the tting.

9. Remove the header from the tank by removing the

six bolts on the metal ring separating the header

from the tank. Slowly and carefully lift the header

out of the DEF tank, exposing the lter unit, to avoid

damaging the lter or other components.

10. Remove the clip, pull the lter cartridge out and

inspect for cracks, damage and contamination

or debris. Clean the lter and reinsert, unless

replacing the lter at service interval or if debris or

damage is evident:

• Discard the lter element and O-ring in

accordance with environmental regulations and

replace with a new lter element.

• Also inspect the after-treatment DEF dosing unit

lter after replacing the tank lter. (Figure 5-19)

11. Lubricate the O-rings with clean DEF uid and install

the new lter element (O-ring side facing outward) in

its seated notch location.

12. Reinstall the lter cartridge into the DEF tank.

13. Reinstall the tank lter header in reverse order

DEF Dosing Unit Filter

The DEF dosing unit lter prevents foreign objects that

may be suspended in the DEF from entering the dosing

system, which draws DEF from the tank, pressurizes

it, and delivers the DEF through a dosing valve. Any

unused DEF is then routed back to the tank. The DEF

dosing unit lter should be replaced every 4500 hours

or three years, whichever comes rst. It is located on

the left inside the rear access panel on the driver’s side.

Maintenance

Rosco CSV Variable Width Chip Spreader5-16

Loading...

Loading...