MACHINE ADJUSTMENTS

Some components of the aggregate delivery system

require occasional minor adjustments. DO NOT adjust

any conveyor component during operation.

Use only Rosco LeeBoy parts if

replacing rubber conveyor components. Using

hard rubber, old conveyor belts or any other rubber

containing fabric or reinforcement will cause rapid

conveyor belt wear and eventual failure.

Loose clothing or long hair can be

entangled in machine components. Wear protective

clothing, stay clear of rotating shafts and use caution

when adjusting conveyor belts and other rotating

components.

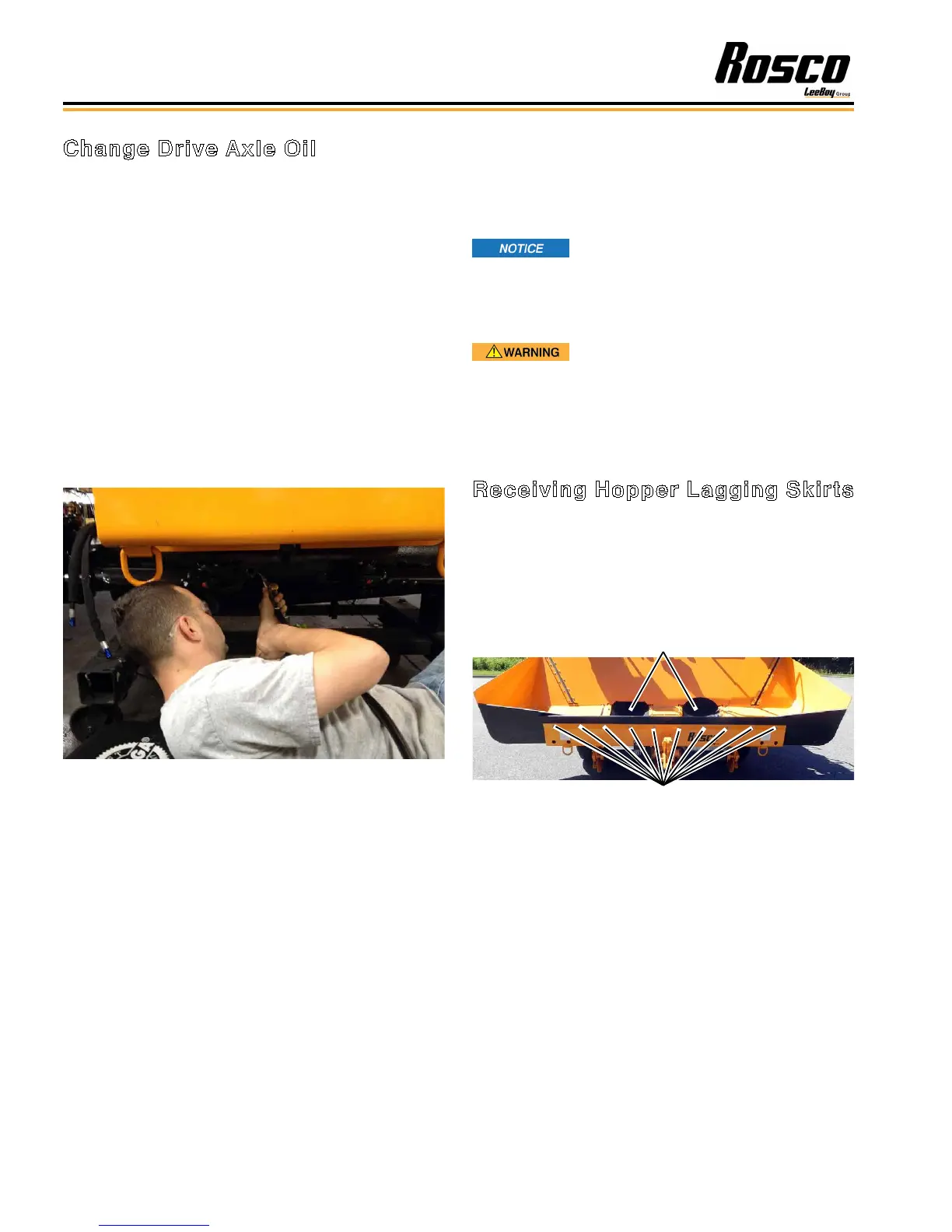

Receiving Hopper Lagging Skirts

The lagging skirts are mounted at the bottom of the

receiving hopper and can easily be adjusted when

needed to ensure contact with the conveyor belts

immediately above the tail pulley. (Figure 5-4)

Check for clearance between the skirts and the belts

periodically.

Conveyors

Skirt Bolts

Figure 5-4. Lagging Skirt Mounting Bolts

Adjust the lagging skirts when necessary by loosening

the skirt mounting bolts and moving the black rubber

skirt until it just touches the conveyor belts.

If the skirt shows excessive wear, contact your

authorized Rosco LeeBoy dealer for replacement.

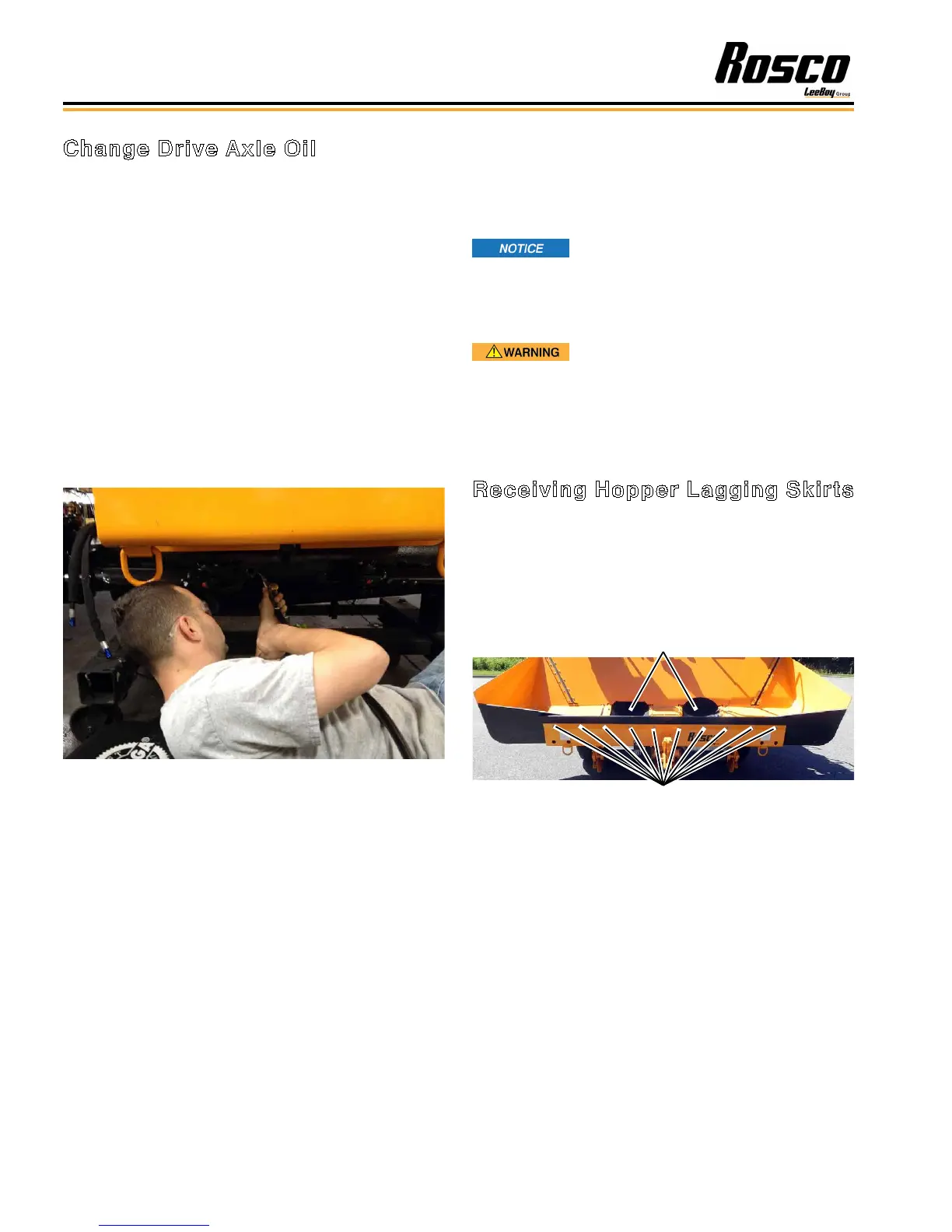

Change Drive Axle Oil

Check the oil level and ll if needed quarterly. Change

the drive axle oil every year for optimum performance.

(Figure 5-3)

To change the drive axle oil:

1. Remove the level plug in the center of the drive axle

housing.

2. Remove the breather plug inside the housing.

3. Add oil until it starts coming out of the level plug.

4. Replace the level plug.

5. Allow the axle to sit level for at least ve minutes to

allow the oil to ow to the hubs.

6. Remove the level plug and check oil level.

7. Add more oil if needed.

Figure 5-3. Changing Drive Axle Oil

Maintenance

Rosco CSV Variable Width Chip Spreader5-8

Loading...

Loading...