Table 5-2. Lubrication Chart

No. ITEM TYPE OF LUBRICANT INTERVAL

1 Auger Extension Bearings (both sides) Multipurpose Grease Daily

2 Spreadroll Extension Bearings (both sides) Multipurpose Grease Daily

3 Individual Gate Bearings (each gate) Multipurpose Grease Daily

4 Drive Shaft (Universal Joints & Slip Yoke) Multipurpose Grease Quarterly

5 Tie Rod Ends Multipurpose Grease Quarterly

6 Steering Cylinder Rod Multipurpose Grease Quarterly

7 Front Axle Oscillation Wheel Bearing Grease Monthly

8 Truck Hitch Multipurpose Grease Daily

9 Conveyor Tail Pulley Bearings (Rear) Multipurpose Grease Weekly

10 Conveyor Head Pulley Bearings (Front) Multipurpose Grease Weekly

11 Auger and Spreadroll Chains Multipurpose Grease Weekly

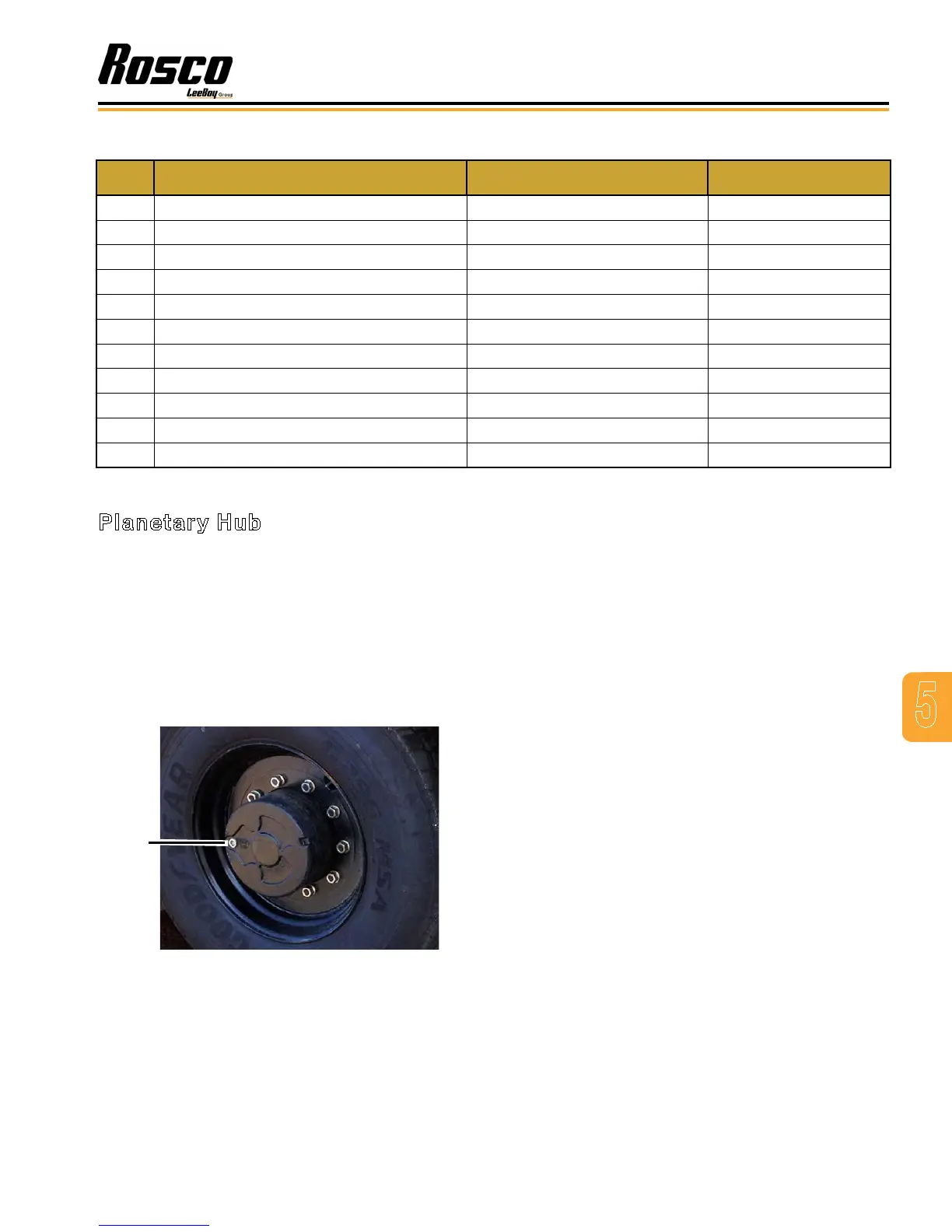

Planetary Hub

The planetary hubs should be checked periodically to

ensure they contain the proper amount of gear lube.

Two drain/ll plugs are located on the outer end of each

planetary hub. The planetary hub is mounted on each

side of the front axle. You will need an assistant to

properly check the gear oil level:

1. With assistance from a ground guide, slowly drive

the machine forward until the planetary hub plug is

at the 3 o’clock or 9 o’clock position. (Figure 5-2)

Plug

Figure 5-2. Planetary Hub Plug in 9 O’Clock Position

2. Shut off the engine and apply park brake.

3. Unscrew the planetary hub plug.

4. Oil should be level with bottom of plug hole.

5. Fill if needed and reinsert plug.

6. Replace the level plug.

7. Allow the axle to sit level for at least ve minutes to

allow the oil to ow to the hubs.

8. Remove the level plug and check oil level.

9. Add more oil if needed.

5

Maintenance

Rosco CSV Variable Width Chip Spreader 5-7

Loading...

Loading...