GENERAL INFORMATION

The CSV Variable Width Chip Spreader is equipped

with a receiving hopper in the rear, moving aggregate

via belt conveyors to the vibrating spread hopper in

the front where adjustable, hydraulic discharge gates

apply material accurately without overlaps. Typically

used on rural roads, subdivisions, parking lots and other

resurfacing jobs, operators can change the aggregate

rate at any time, even while chipping. Efcient and

economical, the CSV Variable Width Chip Spreader

offers superior automation and easy operation.

Only authorized personnel who are

properly trained should operate the Rosco LeeBoy

CSV Variable Width Chip Spreader.

RECEIVING THE MACHINE

Although the machine has been checked thoroughly by

the manufacturer, road hazards or other factors during

transport may result in damage. Be sure to check the

machine thoroughly before operating it:

1. Check engine oil. (Page 5-12)

2. Check hydraulic uid level. (Page 5-21)

3. Check machine hoses for any damage or leaks.

4. Inspect machine for any damage during transport.

Contact your authorized dealer immediately if any

damage has occurred in transit.

Initial and Daily Inspection

The following inspection is essential and should be

performed before the initial start-up. Visually inspect the

unit to check its general condition and for familiarization.

Continue with a check of the systems and components

shown in the table below:

Table 4-1. Initial and Daily Inspection

INSPECT PROCEDURE

Engine Oil

Level

Maintain oil level between ADD and

FULL marks on dipstick.

Fuel Tank

Check for adequate fuel supply. Fill if

needed. Always ll tank at end of the day

to prevent condensation in the tank.

Hydraulic

Tank

Check the tank for oil level and leaks.

Radiator Check coolant level.

Battery

Ensure all cables are tight and clean.

Check for corrosion on the battery

terminals.

Air Cleaner

Check the air lter element and hose

connections. Air cleaner has both a

primary and secondary lter.

Drain Plugs Make sure plugs are inserted and tight.

Engine Belt Check for proper belt tension.

Grease

Fittings

Ensure ttings are greased and in good

working order.

DEF Tank Check uid level daily.

Dual

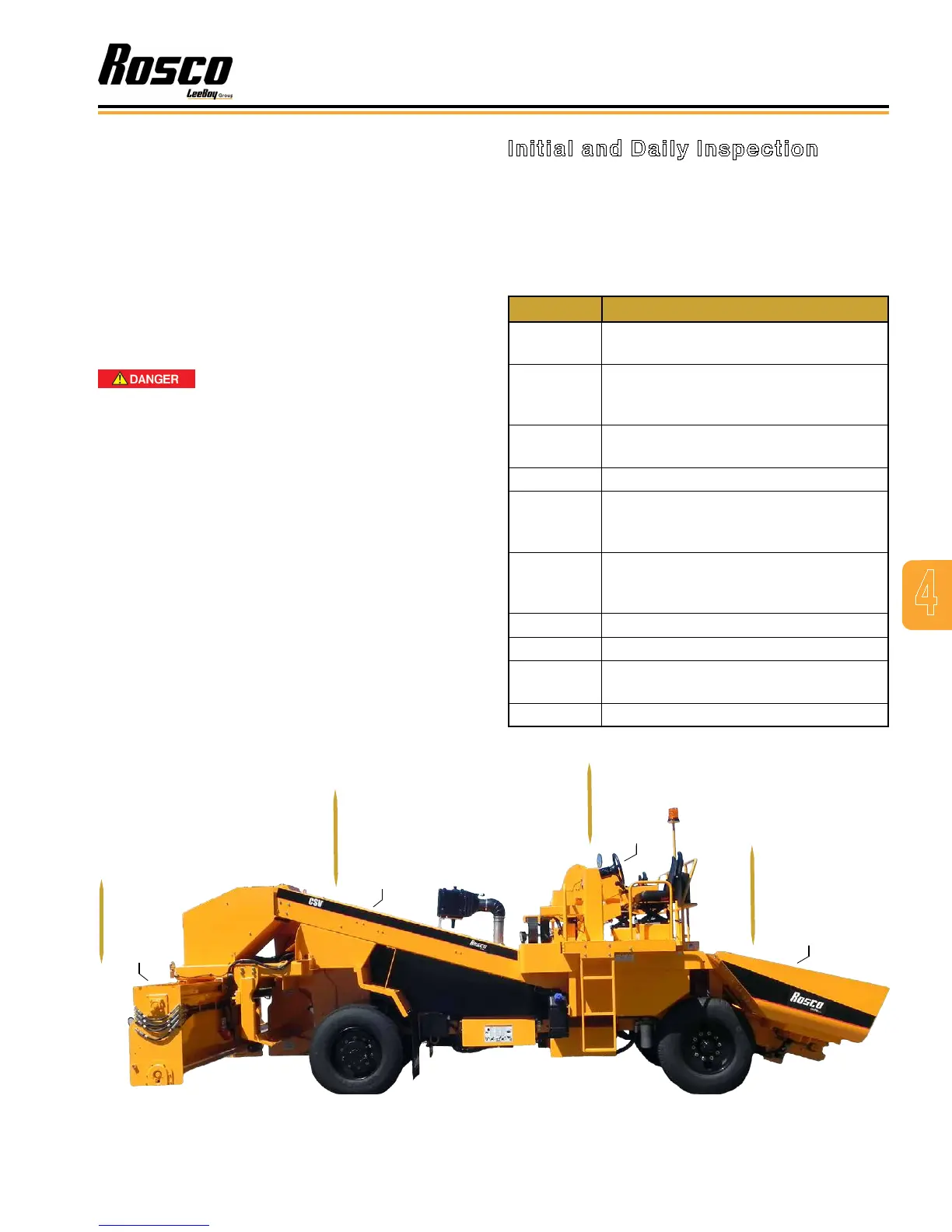

Conveyors

Moves aggregate

from the receiving

hopper in rear to

spread hopper.

Receiving

Hopper

Hopper wings open

and close for added

truck clearance. Holds

up to 3.5 cubic yards.

Spread

Hopper

Fully extends

to a width up

to 16 feet.

•

•

Operator

Platform

Platform(s)

extends and

retracts.

•

•

4

Operation

Rosco CSV Variable Width Chip Spreader 4-3

Loading...

Loading...