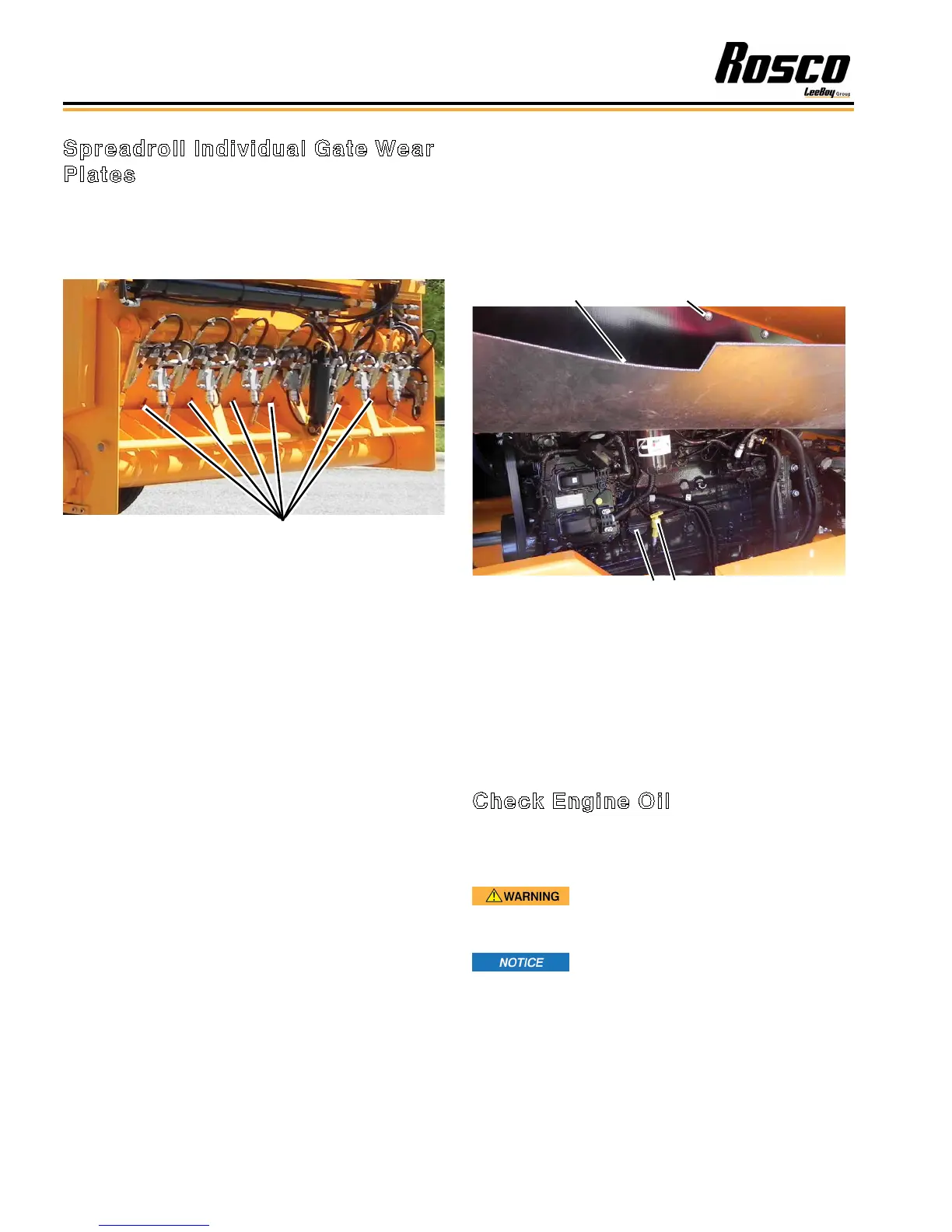

ENGINE MAINTENANCE

The Rosco CSV816 Variable Width Chip Spreader

features a Cummins QSV6.7 Tier 4F diesel engine.

You can access engine components by removing the

access panel on the left side of the machine. (Figure

5-13)

3 4

Figure 5-13. Engine Access Panel, Oil Cap, Dipstick

and Filter

1 - Engine Access Panel

2 - Access Panel Bolts

3 - Engine Oil Cap

4 - Oil Dipstick

Check Engine Oil

The engine lubrication oil must be kept at a level above

the ADD mark, but not above the FULL mark, on the

engine lubrication oil dipstick.

ALWAYS stop the engine before

checking the engine lubrication oil level as hot oil

can be thrown, causing serious injury.

Wait ve minutes after engine

shutdown before removing the dipstick from the

engine and checking the oil level to assure accuracy.

This also prevents lling the engine with too much

lubrication oil. Engine oil should be warm when

checked.

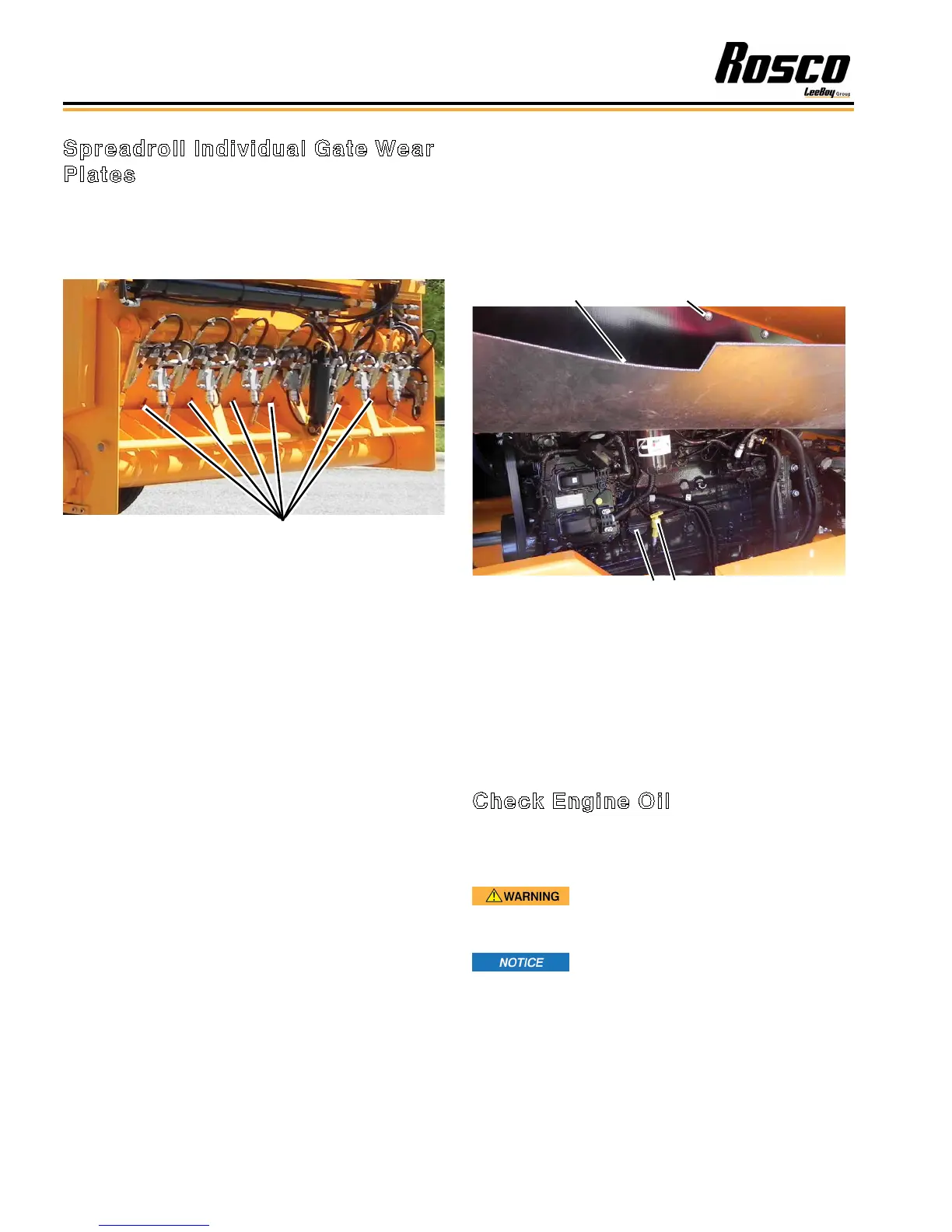

Spreadroll Individual Gate Wear

Plates

The spread hopper wear plates are adjustable and

reversible. Check this adjustment every 50 hours of

service. The adjusters are located behind the spreading

gates. (See Page 5-26 for wear plates replacement.)

Adjuster Bolts

Figure 5-12. Gate Wear Plate Adjusters

To adjust the wear plates:

1. Extend the spreading gates completely.

2. Loosen the adjuster bolts. (Figure 5-12)

3. Slide the spreadroll seal to obtain an even 1/16-inch

(1.59 mm) gap between the seal and the spreadroll,

then retighten each bolt.

Maintenance

Rosco CSV Variable Width Chip Spreader5-12

Loading...

Loading...