Air Filter

Turbo-charged engines are especially demanding on air

lter performance. The operator should be continually

aware of the condition of the air lter system. Inspect

all components for damage, cracked hoses or loose

clamps. Replace the lter every 100 service hours. The

air lter is mounted on top of the engine sound shield

between the two conveyers. (Figure 5-15) A restriction

indicator is mounted on the side of the outlet that should

be checked often. If the red indicator is visible, the air

cleaner element must be replaced.

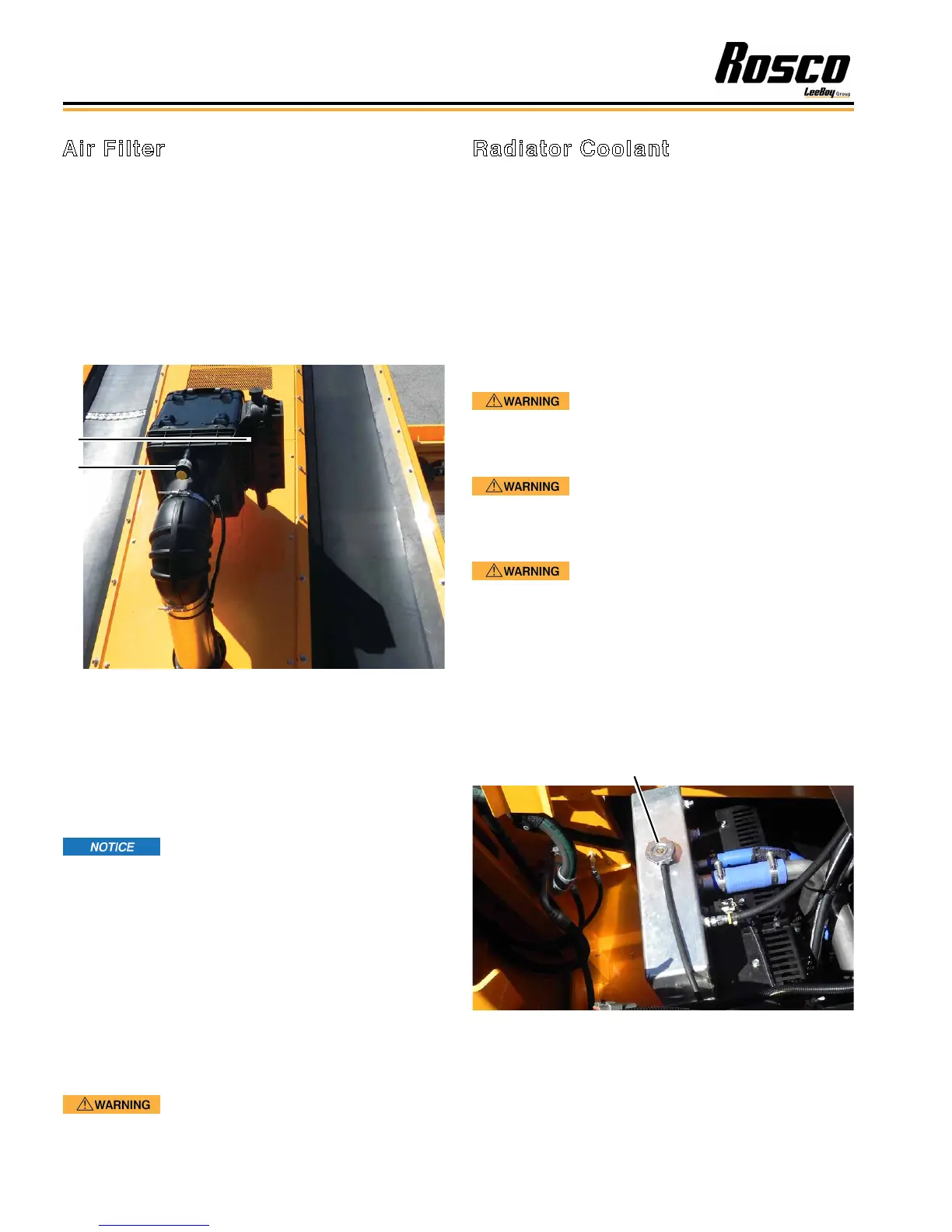

1

2

Figure 5-15. Air Filter Box

1 - Precleaner

2 - Indicator

As the air lter becomes more clogged, the air pressure

increases, causing the indicator to illuminate. When

this occurs, the air lter must be cleaned or replaced as

follows:

Be sure to clean the inside of the air

cleaner body before replacing the air lter element.

Be careful not to introduce any contaminants into the

engine intake tube.

1. Open clamps securing the cover on the lter

housing, then remove the cover.

2. Remove the lter cartridge.

3. Replace with the new lter cartridge.

4. Reinstall cover and secure with the clamps.

5. Reset the lter indicator by pressing button on top of

the indicator.

NEVER operate machine without air

lter to prevent destruction of the engine.

Radiator Coolant

Check the radiator daily to ensure the radiator is full

and that no debris is present as this could block the

system and cause overheating. (Compressed air can

be used to remove any debris from the radiator.) You

can access the radiator surge tank ll cap via the front

access door between the two conveyors.

When the engine is cold, the coolant level should cover

the radiator core. If low, ll with a solution of 50 percent

water and 50 percent ethylene-glycol antifreeze. Flush

the radiator system every 500 service hours (see your

Engine Operator Manual for more information).

DO NOT remove the radiator surge

tank cap while the engine is still hot. The radiator is

under pressure and the hot water can cause serious

injury.

Avoid prolonged and repeated skin

contact with used antifreeze as contact can cause

skin disorders or injury. Wash thoroughly after any

contact.

ALWAYS wear eye protection when

using compressed air to prevent injury.

To check the radiator or add coolant:

1. Open the access door to access the radiator surge

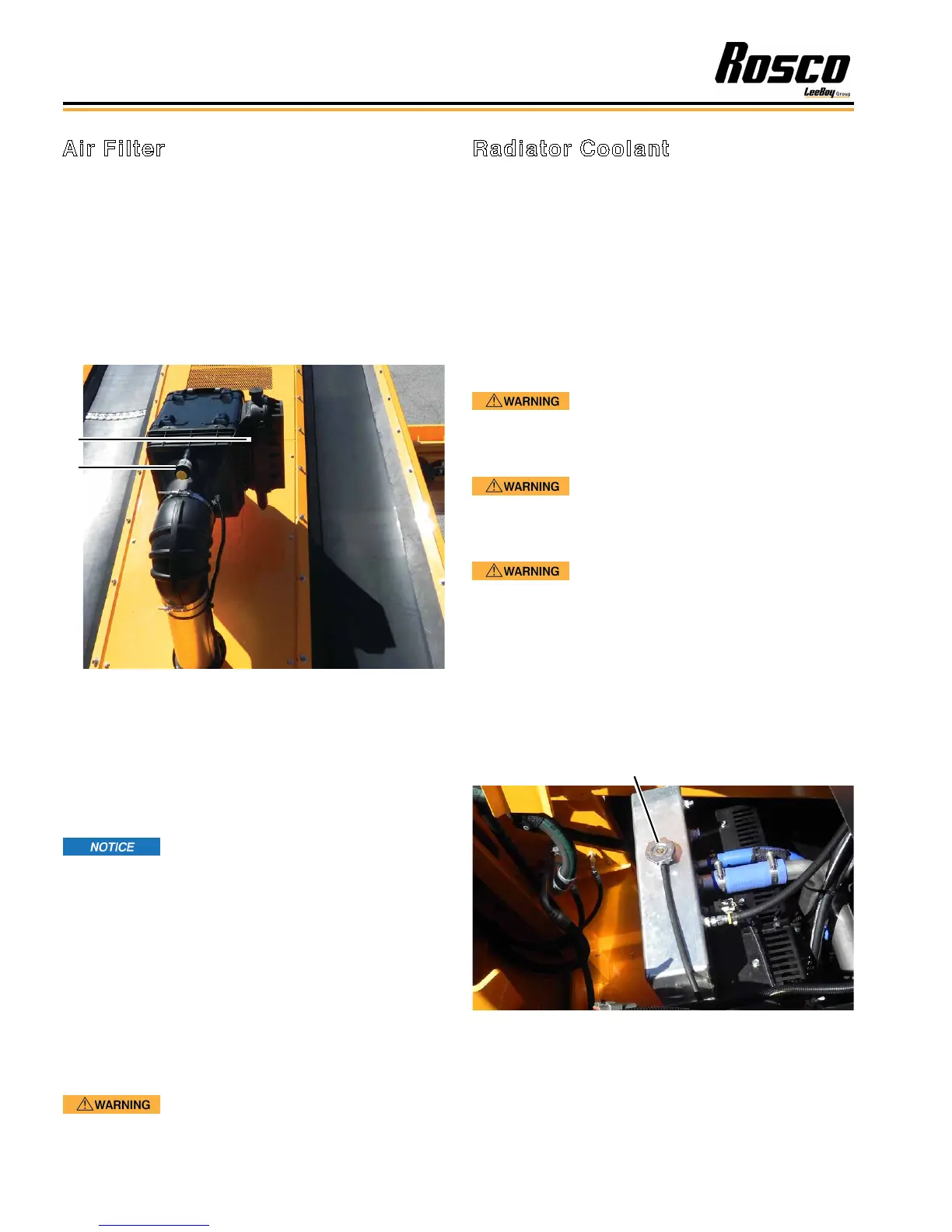

tank cap. (Figure 5-16)

2. Remove the cap to check ONLY WHEN UNIT IS

COOL. Coolant level should be visible.

3. If coolant level is low, add coolant. DO NOT overll.

Radiator Cap

Figure 5-16. Engine Radiator Surge Tank Fill Cap

Maintenance

Rosco CSV Variable Width Chip Spreader5-14

Loading...

Loading...